Quick connector coupler

A connector, fast technology, applied in the direction of coupling, mechanical equipment, etc., can solve the problems of large volume, difficult to assemble, complex design and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

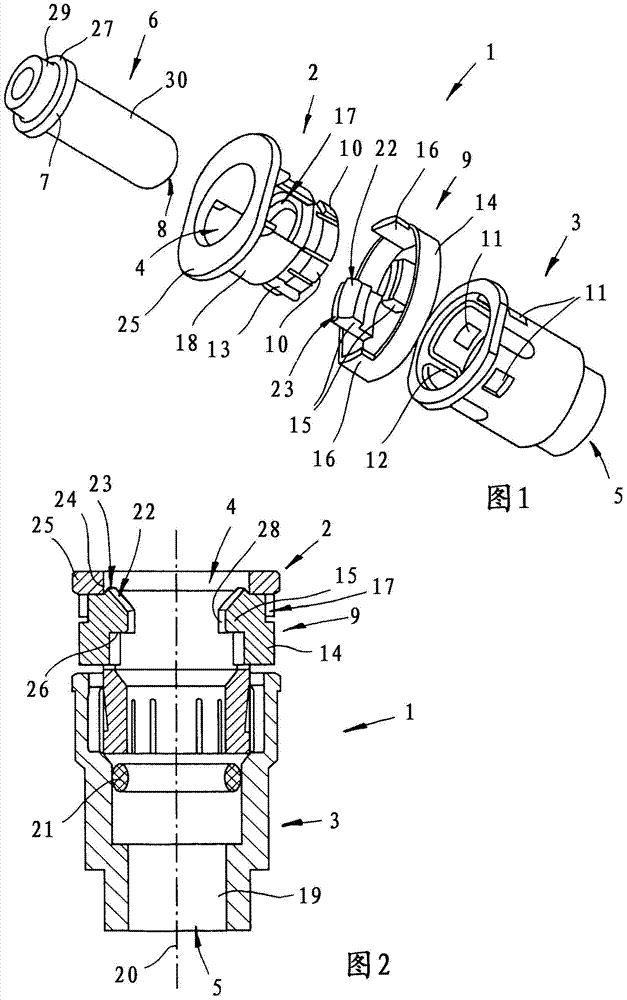

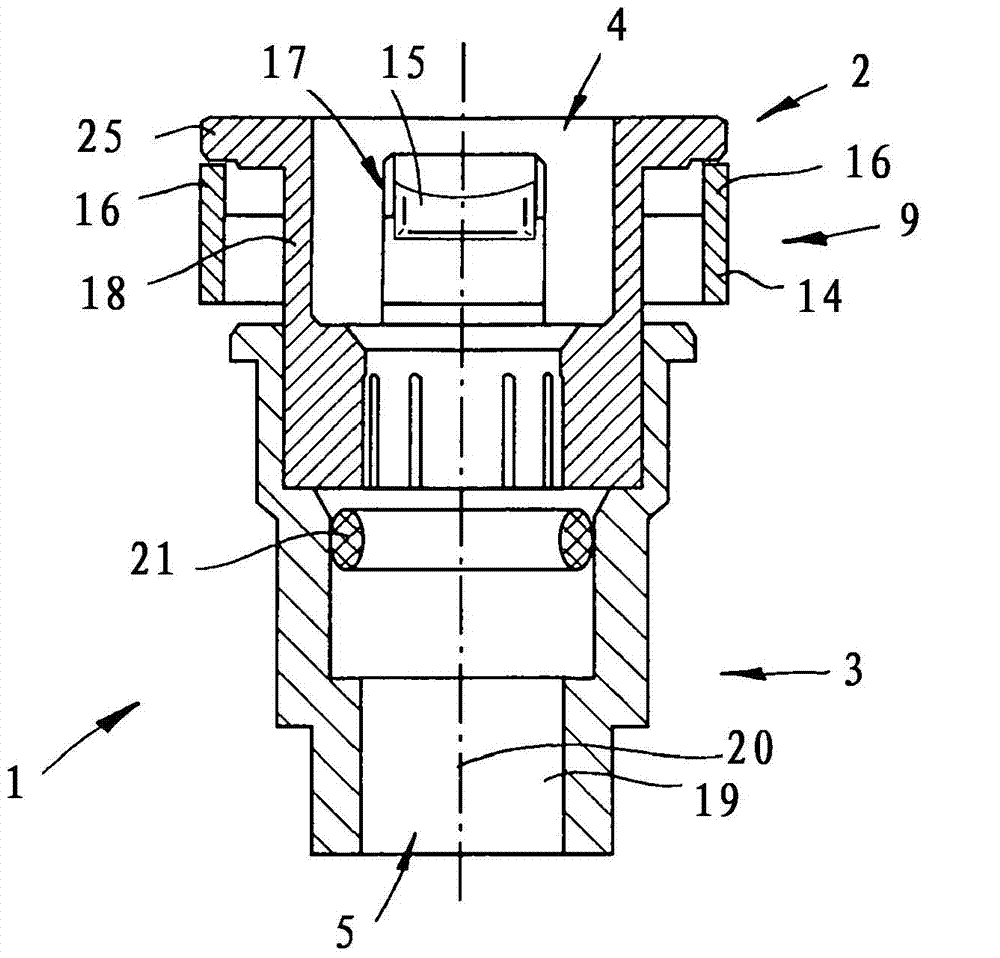

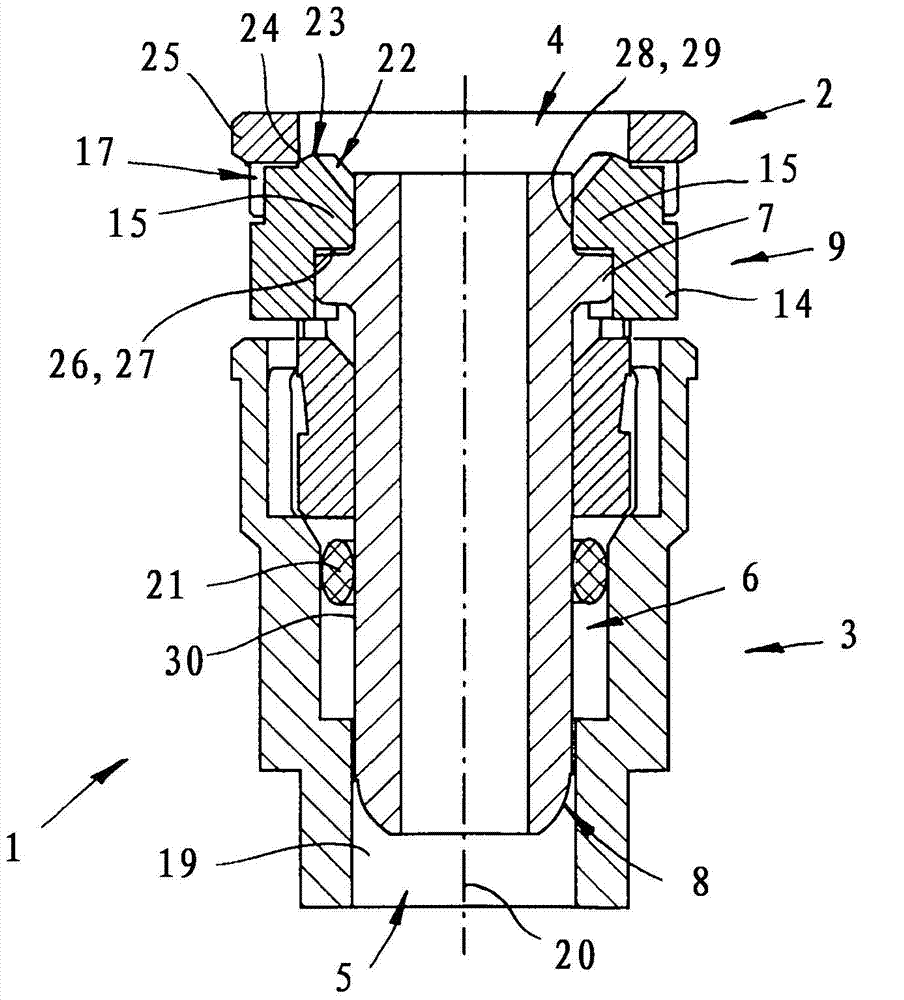

[0060] exist figure 1 , a quick connector fitting 1 is shown comprising a substantially cylindrical hollow body comprising a head element 2 connected to a sealing element 3 . These elements are along the Figures 2 to 4 The shown longitudinal axis 20 defines the through bore 19 . The head element 2 comprises at one end a male member inlet port 4 formed by a cylindrical surface 24 in a cover 25 at the end of the head element 2 . The opposite end comprises an insert portion comprising a wall 80 with a slot in the axial direction. according to figure 1 , the sealing element 3 comprises an outlet port 5 at the end axially furthest from the head element 2 . As shown, the end of the sealing element 3 defining the outlet port 5 is configured to define a barbed hose connection aligned along the longitudinal axis 20 . As is common in quick connector constructions, the barbed hose connection end of the connector body may be disposed at an angle, such as at a ninety degree (90°) ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com