Quick Connector Fitting

A connector, fast technology, applied in the direction of coupling, mechanical equipment, etc., can solve the problems of large volume, complex design, difficult to assemble, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

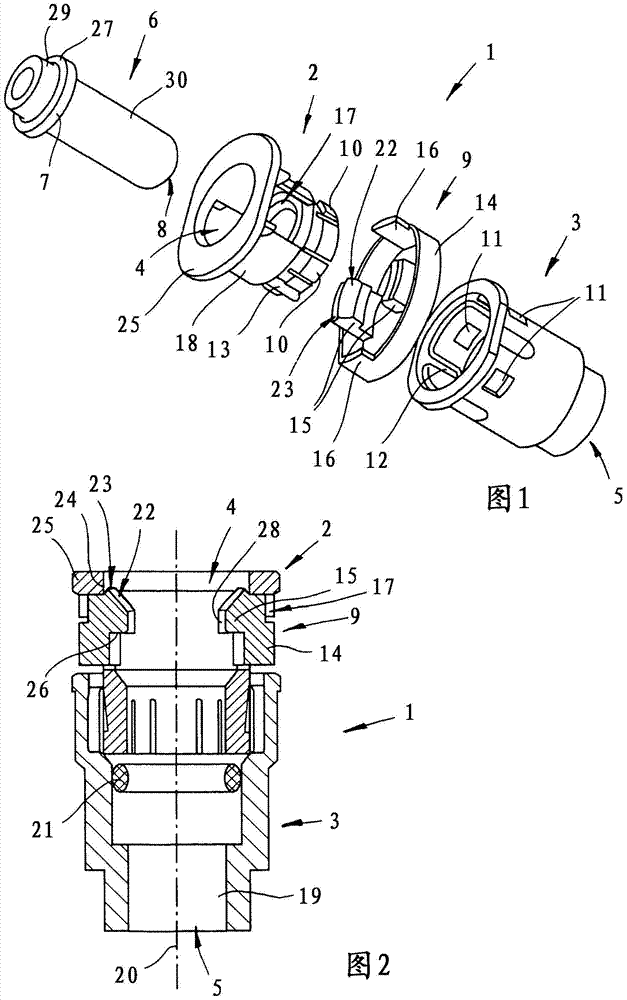

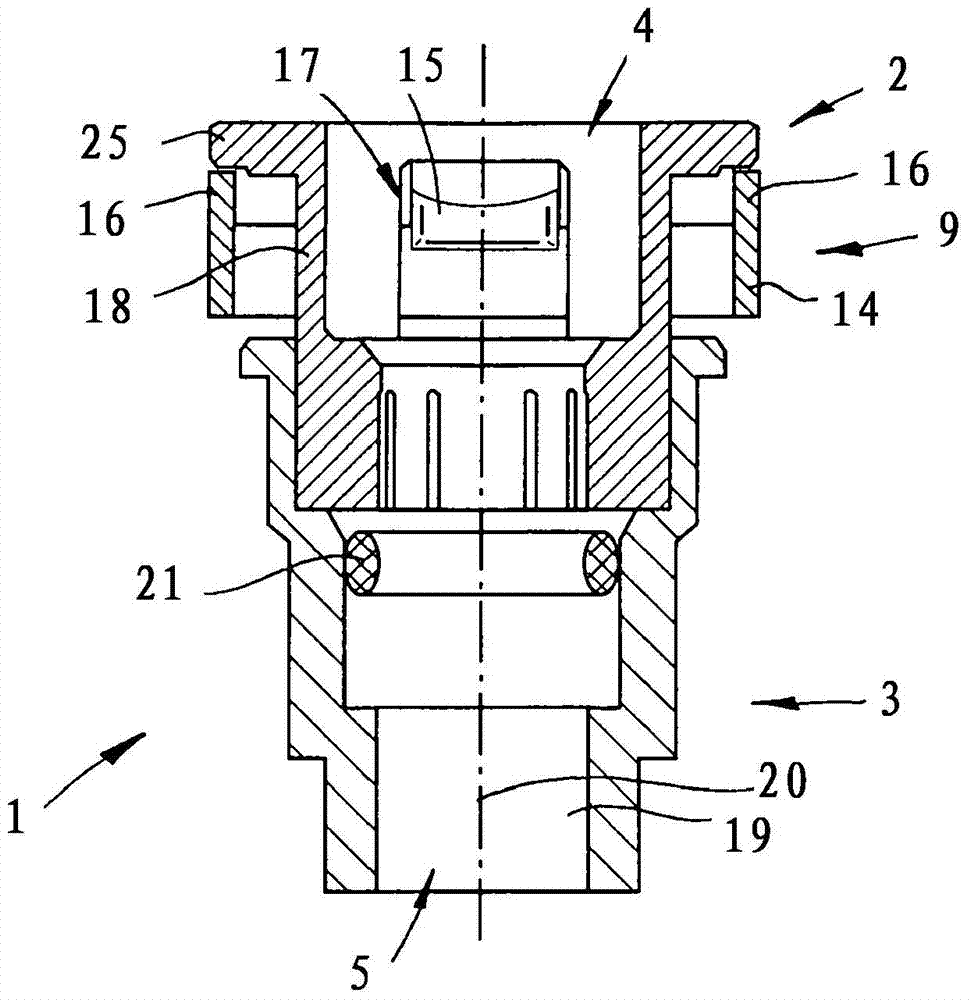

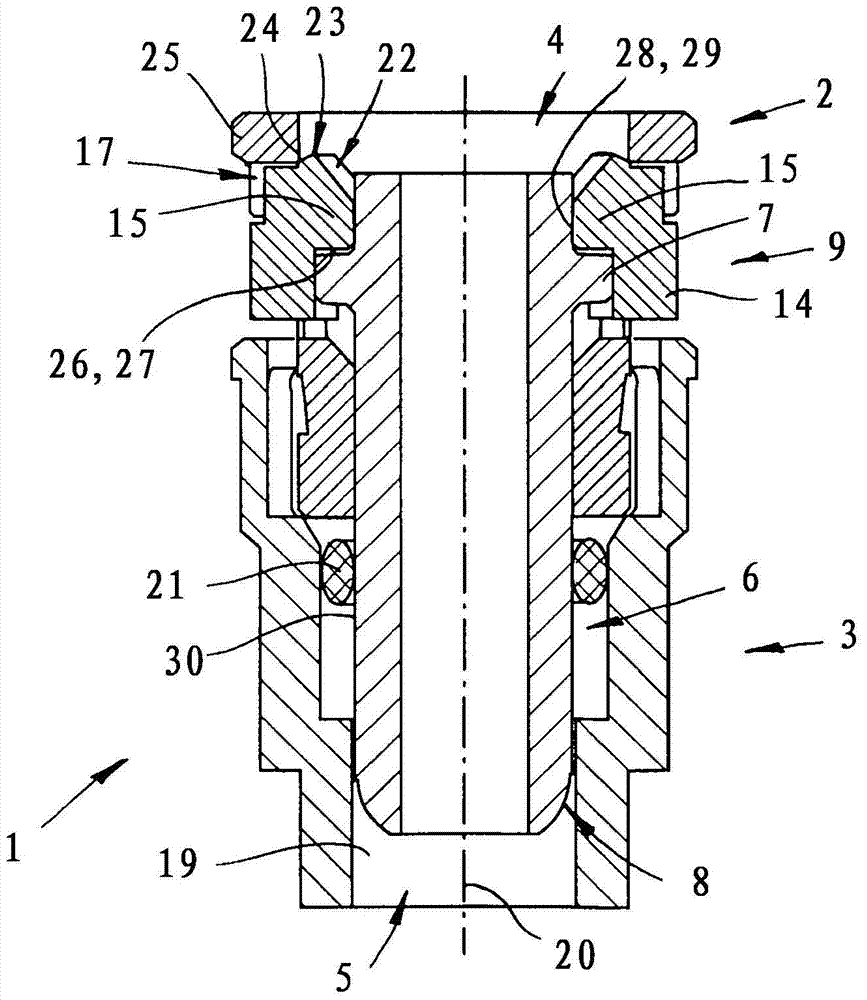

[0060] in figure 1 Here, a quick connector joint 1 is shown, which includes a generally cylindrical hollow body including a head element 2 connected to a sealing element 3. These elements are along Figure 2 to 4 The longitudinal axis 20 shown defines a through hole 19. The head element 2 includes a male member inlet port 4 at one end, which is formed by a cylindrical surface 24 in the cover 25 at the end of the head element 2. The opposite end includes an insertion portion including a wall 80 having a slot in the axial direction. according to figure 1 The sealing element 3 includes an outlet port 5 at the end farthest from the head element 2 in the axial direction. As shown in the figure, the end of the sealing element 3 that defines the outlet port 5 is configured to define a barbed hose connection aligned along the longitudinal axis 20. As commonly used in quick connector construction, the barbed hose connection end of the connector body can be set at an angle relative to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com