Lubricating device with automatic oil replenishment

A lubricating device and automatic oil replenishment technology, applied in the direction of engine lubrication, lubricating parts, lubricating oil input, etc., can solve problems such as time waste, reduce the number of parts, improve equipment utilization rate, and save downtime for refueling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

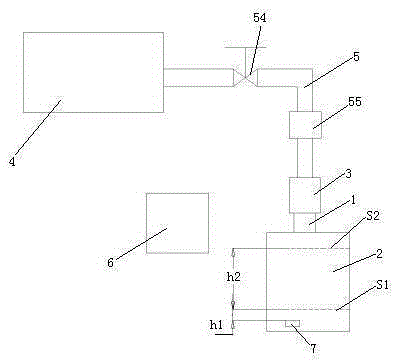

[0024] Embodiment one, see figure 1 , a lubricating device that can automatically replenish oil, including a lubricating oil tank 2, a main oil tank 4 and a control unit 6. An oil quantity sensor 7 is installed in the lubricating oil tank 2 . The fuel quantity sensor 7 is a pressure sensor. The oil quantity sensor 7 and the control unit 6 are electrically connected together. Lubricating oil tank 2 is provided with oil pipe interface 1. The oil pipe interface 1 is located at the upper end of the lubricating oil tank 2 . The main oil tank 4 is located above the lubricating oil tank 2 . The outlet of the main oil tank 4 is provided with an oil pipe 5 . Oil pipe 5 and main oil tank 5 are connected together by flexible pipe. Oil pipe 5 and oil pipe interface 1 are butted together. A sealing ring is arranged between the oil pipe 5 and the oil pipe interface 1 . Oil pipe 5 and oil pipe interface 1 are fixed together by connecting nut 3 . The oil pipe 5 is provided with a man...

Embodiment 2

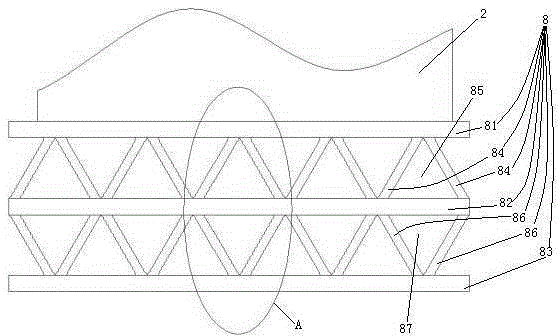

[0026] Embodiment two, see figure 2 , the difference with the first embodiment is: a mounting frame 8 is also provided. The mounting frame 8 includes an upper base plate 81 , a middle base plate 82 and a lower base plate 83 distributed along the vertical direction. A number of inclined support plates 84 are provided between the upper base plate 81 and the middle base plate 82 . Several upper deformation channels 85 extending along the horizontal direction are enclosed between the upper base plate 81 , the middle base plate 82 and the upper inclined support plate 84 . The upper deformation channel 85 is triangular. Between the lower base plate 83 and the middle base plate 82 are provided several downwardly inclined support plates 86 . A plurality of lower deformation channels 87 extending along the horizontal direction are enclosed between the lower base plate 83 , the middle base plate 82 and the lower inclined support plate 86 . The lower deformation channel 87 is triang...

Embodiment 3

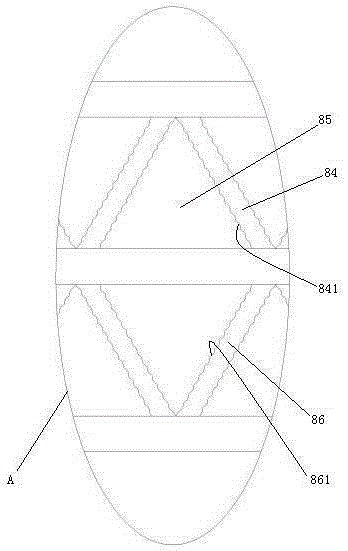

[0029] Embodiment three, see Figure 4 , The difference with the second embodiment is: the two ends of the upper deformation channel 85 and the lower deformation channel 87 are provided with end caps 80, so that the upper deformation channel 85 and the lower deformation channel 87 form a closed cavity. The upper inclined support plate between the adjacent upper deformation channels 85 in the upper inclined support plate 84, the lower inclined support plate between the adjacent lower deformation channels 87 in the lower inclined support plate 86, and the middle base plate 82 are located on the corresponding A damping channel 88 is provided at the position between the adjacent upper deformation channel and the lower deformation channel. Both the upper deformation channel 85 and the lower deformation channel 87 are filled with damping fluid (the damping fluid is not shown in the figure). The upper deformation channel 85 and the lower deformation channel 87 are provided with an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com