Experimental device for shale movable oil ration determination

A quantitative measurement and experimental device technology, applied in the direction of material inspection products, etc., can solve the problem of only measuring part of the movable oil amount, unable to quantitatively measure, unable to determine the movable oil amount, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the above-mentioned and other objects, features and advantages of the present invention more obvious and understandable, preferred embodiments are listed below in conjunction with the accompanying drawings, which are described in detail as follows.

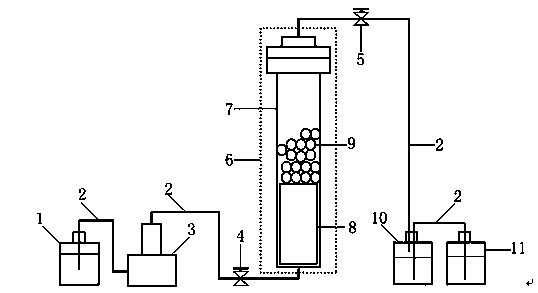

[0018] Such as figure 1 As shown, figure 1 It is a structural diagram of the experimental device for quantitative determination of shale movable oil of the present invention. The experimental device for quantitative determination of shale movable oil consists of formation water container 1, stainless steel pipeline 2, high pressure constant pressure pump 3, first valve 4, second valve 5, heating furnace 6, autoclave 7, oil collection bottle 10 and overflow Composition of flow bottle 11. The high-pressure constant-pressure pump 2 is connected between the formation water container 1 and the autoclave 7, and injects the fluid in the formation water container 1 into the sample in the autoclave 7, and controls th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com