Transparent film having micro-convexoconcave structure on surface thereof, method for producing same, and substrate film used in production of transparent film

A technology of fine concave-convex structure and transparent film, which is applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, application, etc., can solve problems such as poor refractive index and poor appearance, and achieve excellent adhesion and good appearance quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

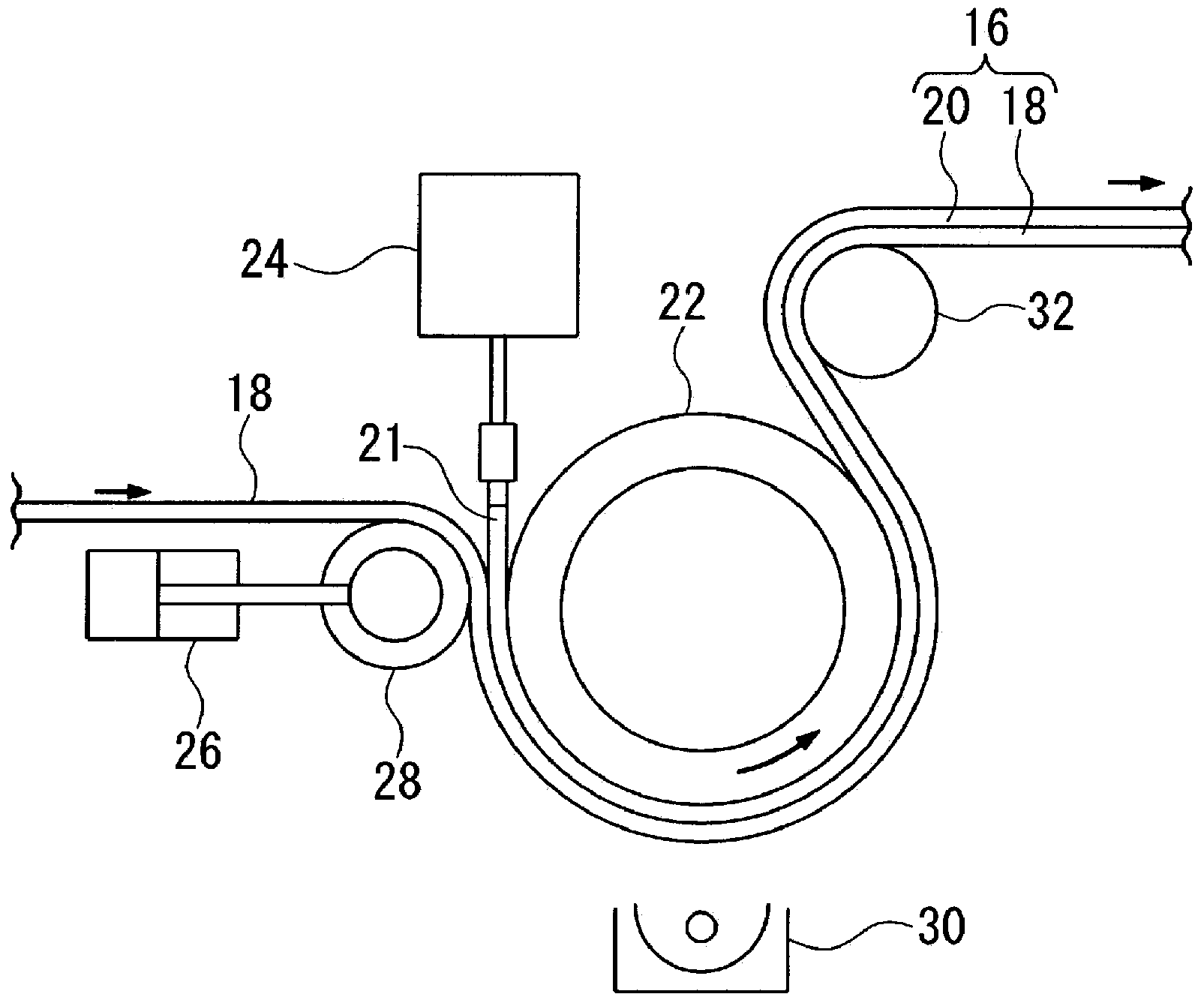

[0252] use figure 2 The fabrication setup shown produces transparent films.

[0253] As the roll-shaped die 22, the aforementioned die a was used.

[0254] As the active energy ray-curable resin composition 21, the active energy ray-curable resin composition A shown in Table 1 was used.

[0255] As the base film 18, an acrylic film having the maximum valley depth Pv and the average width RSm of the contour elements shown in Table 3 was used. In addition, the value of the maximum height roughness Rz (according to JISB0601:2001) is recorded as a reference.

[0256] The coating film of the active energy ray-curable resin composition A is irradiated with a cumulative light intensity of 1000 mJ / cm from the base film 18 side 2 The active energy ray-curable resin composition A is cured by ultraviolet rays. The temperature of the surface of the mold a when the active energy ray-curable resin composition A was cured was 70°C.

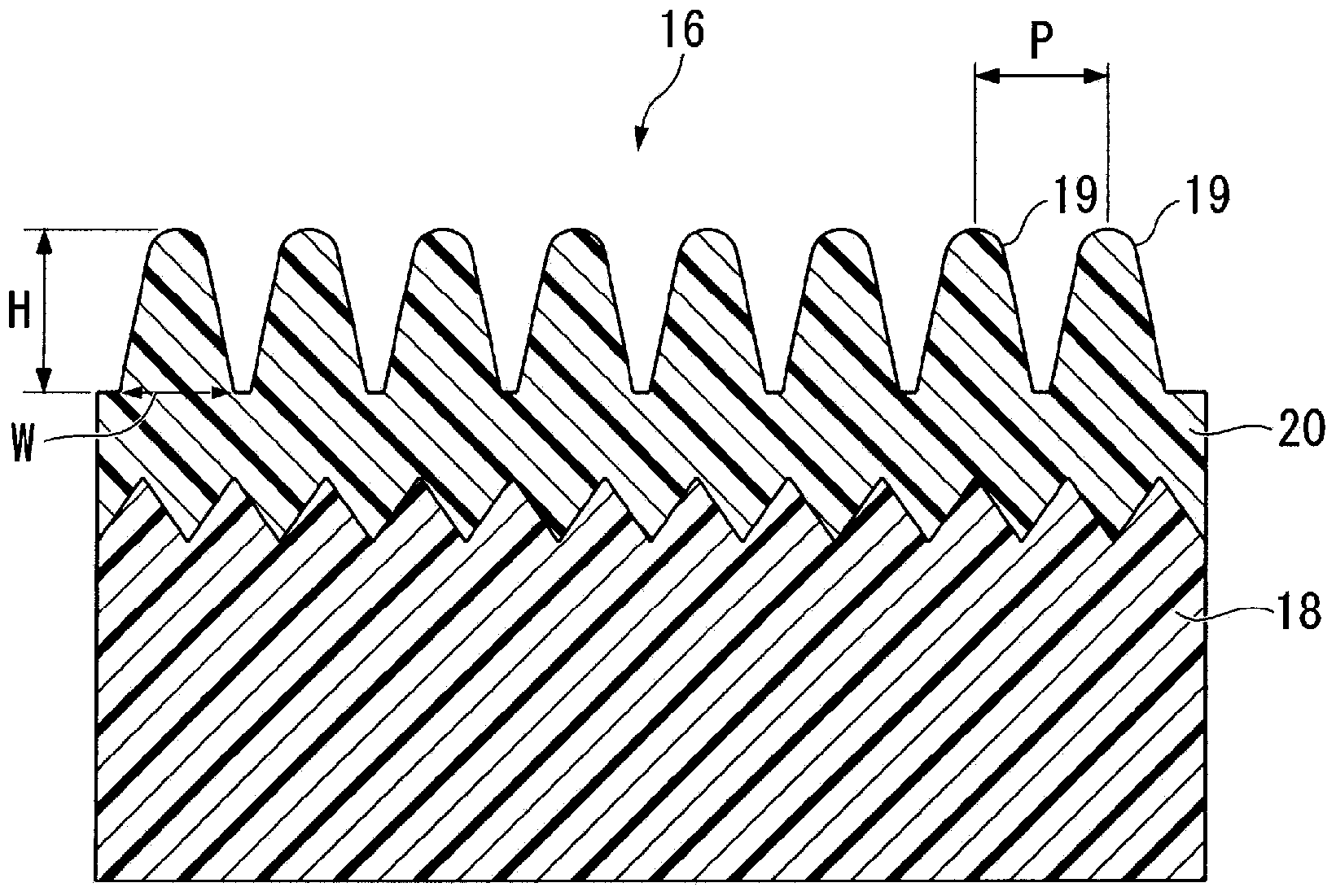

[0257] The average period of the protrusions of the ...

Embodiment 2~6、 comparative example 1~2)

[0259]Except having used what is shown in Table 3 as the active energy ray-curable resin composition 21 and the base film 18, and having changed the temperature of the mold 22, it carried out similarly to Example 1, and manufactured the transparent film.

[0260] Table 3 shows the evaluation results of the adhesiveness and appearance of the transparent film.

[0261] [table 3]

[0262]

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com