Method for low-temperature puffing drying of fruits and vegetables

A low-temperature puffing, fruit and vegetable technology, applied in the direction of preservation of fruits/vegetables by dehydration, etc., can solve the problems of destroying basic nutrients, pigments and flavor substances, unfavorable retention of active ingredients, and loss of nutrients, etc. The effect of good feeling and low equipment investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Method for drying autumn spinach by low-temperature puffing with mixed gas

[0028] Pick spinach with 85% moisture content in autumn, remove roots and miscellaneous leaves, wash with water and place in a drying box to remove free water to a moisture content of 25%, then move to a puffing reactor and vacuum to 0.05MPa , Charge CO with a volume ratio of 3:17 2 And N 2 , Make the pressure in the reactor reach 1.0MPa, maintain the temperature at 4°C, and after maintaining the pressure for 20 minutes, the pressure will drop to normal pressure instantaneously within 3 seconds to expand and dehydrate the material.

[0029] Take the material out and put it in the drying box, and dry it until the moisture content is 4%. 2 The sealed package is protected and opened when used, and the shelf life can reach 18 months.

[0030] Before puffing, the spinach branches with one stalk and leaf can be loosened in a bundle of 5-7 roots, and the lower leaves of the stalk can be erected to...

Embodiment 2-5

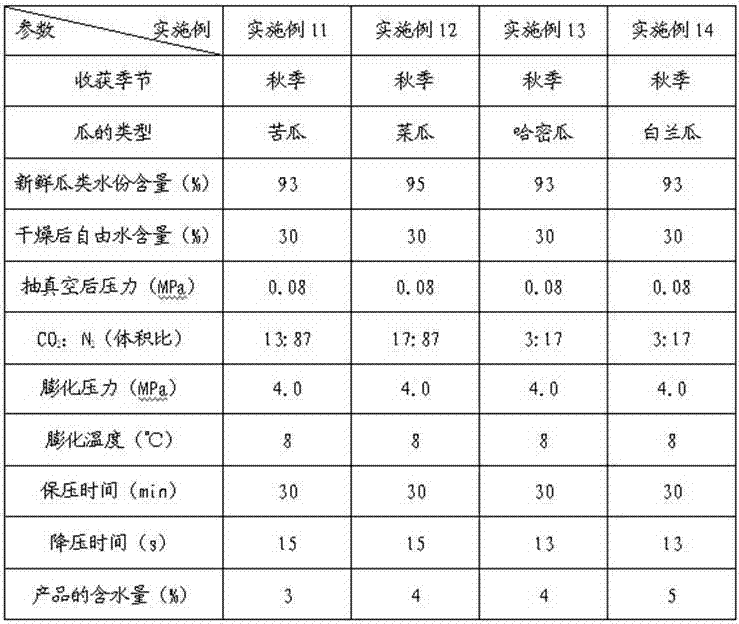

[0033] Example 2-5 Method for drying other types of spinach by low-temperature puffing and drying of mixed gas

[0034] Examples 2-5 are methods for using mixed gas to puff and dry spinach produced in other seasons at low temperature. The preparation method is the same as that of Example 1, except that the corresponding control parameters during the preparation process are different. See Table 1 for details.

[0035] Table 1 Relevant technical parameters of spinach produced in other seasons using mixed gas low-temperature puffing and drying

[0036]

[0037] The color of the products produced in Examples 2-5 is emerald green, the rehydration is good, the color after rehydration is brighter than the undehydrated material, the color retention time is long, and the nutrients are retained to the utmost extent. The treatment process has low expansion pressure, low equipment investment cost, high safety factor, easy operation, and high economic and social benefits.

Embodiment 6

[0038] Example 6 Method for drying long beans by low-temperature puffing with mixed gas

[0039] After picking the long beans with 83% moisture content in autumn, wash them with water and cut them into 2-3cm-long sections. Place them in a drying box to remove free water until the moisture content is 20%; move to the puffing reactor and vacuum To the pressure of 0.1MPa, charge CO with a volume ratio of 1:4 2 And N 2 The pressure in the reactor reaches 2.8MPa, the temperature is maintained at 10℃, the pressure is maintained for 45min, and the pressure drops to normal pressure instantly (20s), so that the material is expanded and dehydrated. Take the material out and put it in a drying box, and dry it to a moisture content of 3%. 2 Under the protection, sealed and packaged and stored for immediate use, the shelf life can reach 18 months.

[0040] The finished product has a bright green color and good rehydration. After rehydration, the color is brighter than that of the undehydrated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com