Rubber-covered roller surface plate brushing device

A technology of surface plate and rubber roller, which is applied to the device and coating of surface coating liquid, which can solve the problems of low efficiency and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

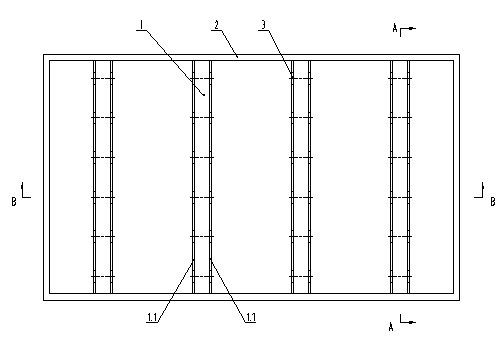

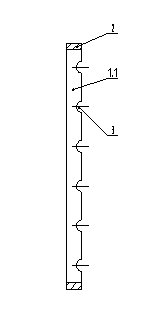

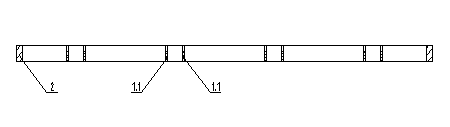

[0014] The rubber roller surface plate coating device shown in the accompanying drawings includes a frame 2, at least one strip-shaped support assembly 1 for supporting the rubber roller; the support assembly 1 is fixedly connected in the frame 2; the upper surface of the support assembly 1 is provided with several Groove 3; the groove 3 is of equal height in the height direction; preferred solution: the support assembly 1 is composed of at least two parallel and vertical support plates 1.1, and the upper surface of the support plate 1 is provided with several grooves 3. In this embodiment, four sets of support assemblies 1 are arranged inside the frame 2, and each set of support assemblies 1 is composed of two support plates 1.1.

[0015] When the present invention is in use, the rubber roller 4 to be treated is placed flat in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com