Vehicle active transverse stabilizer bar

A stabilizer bar, active technology, applied to vehicle components, interconnection systems, suspensions, etc., can solve the problems of limited ability to resist body roll, difficult to meet vehicle handling stability and comfort, and achieve increased resistance Roll stiffness, compensation for the lack of ability to resist large-scale roll of the body, and the effect of changing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

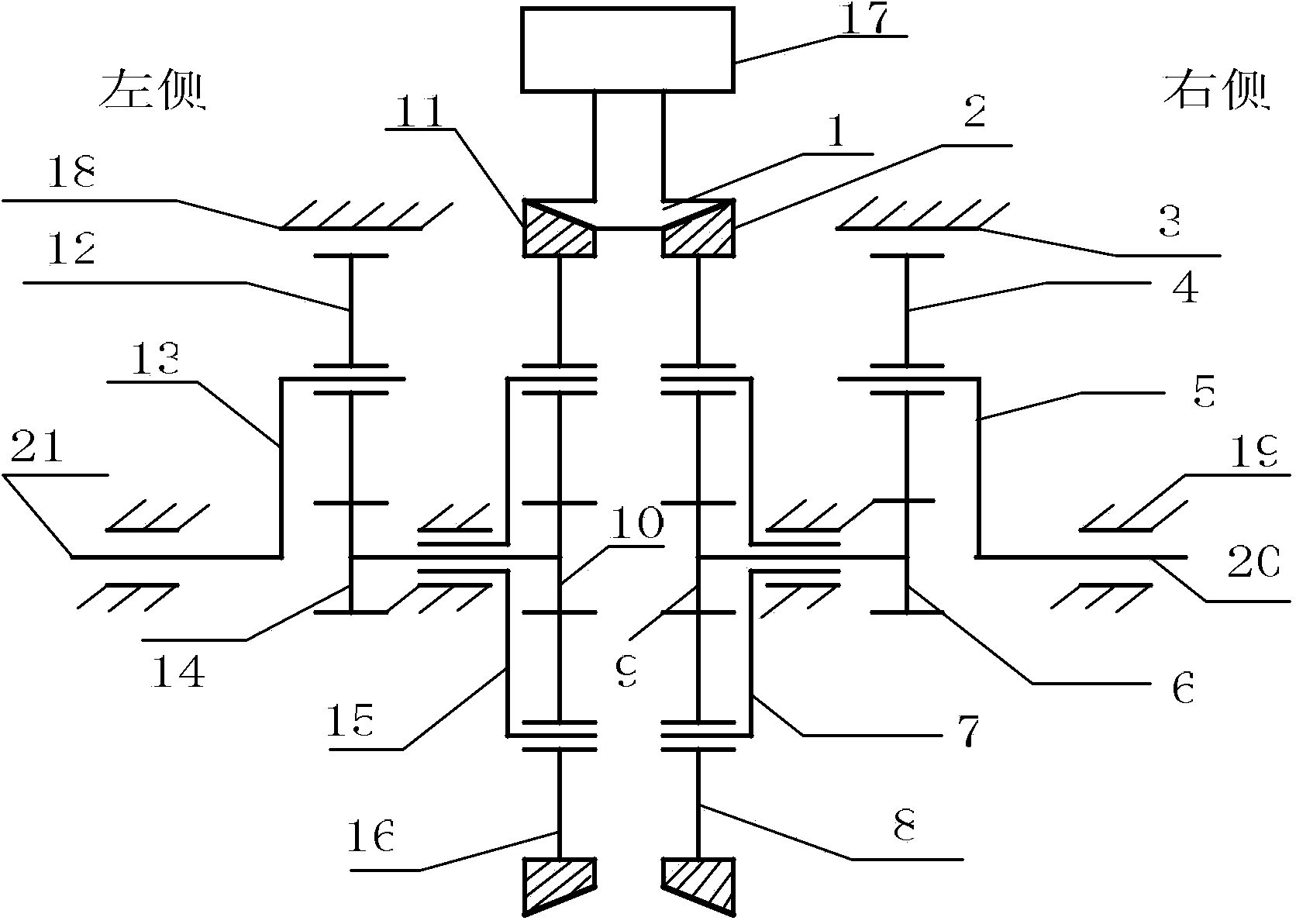

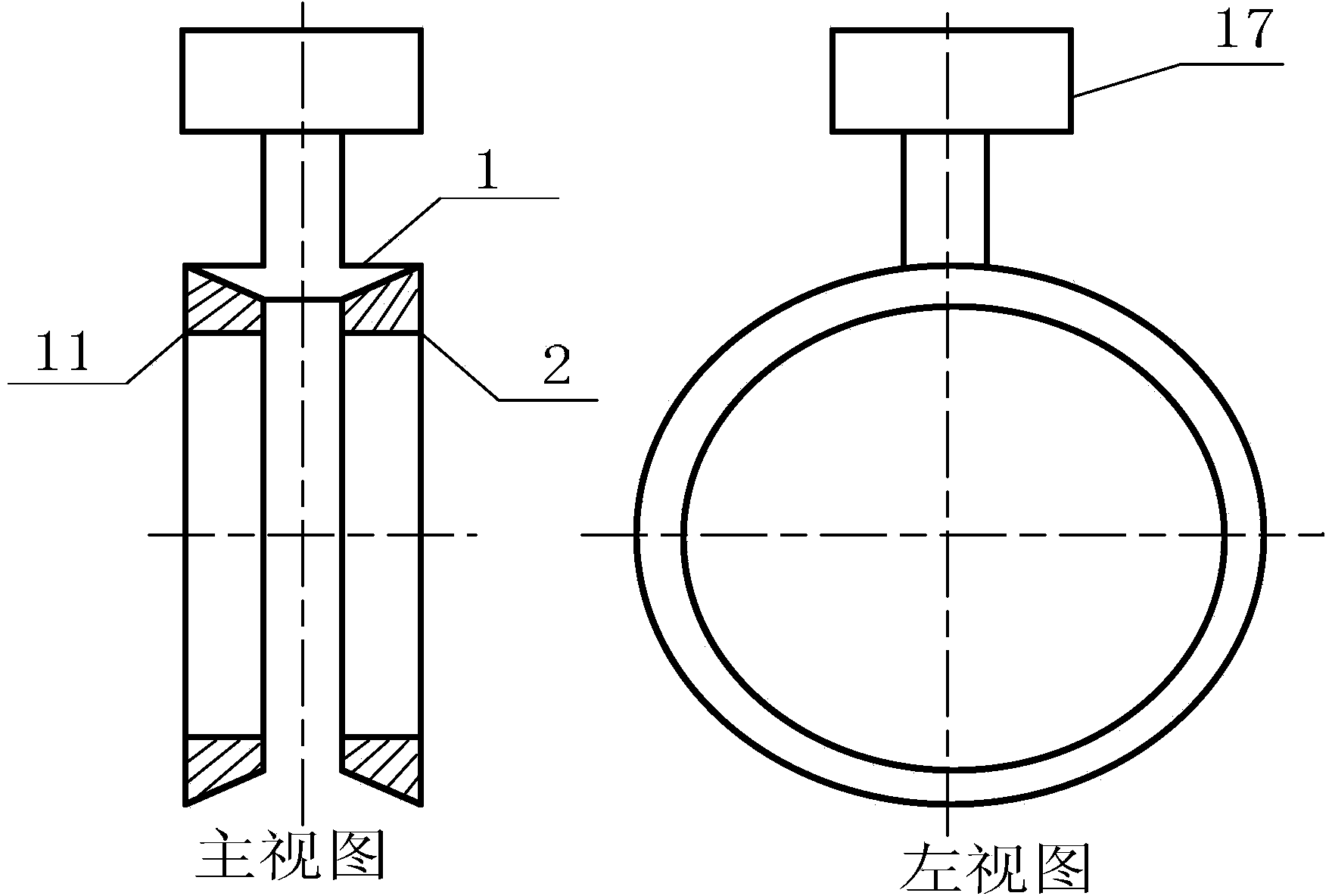

[0020] figure 1 with figure 2 It shows an embodiment of a vehicle active stabilizer bar of the present invention, which includes a bevel gear 1 at the output end of the servo motor; the first ring gear 2 on the right side of the planetary gear mechanism; the second ring gear on the right side of the planetary gear mechanism Ring gear 3; the second planetary gear 4 on the right side of the planetary gear mechanism; the second planetary carrier 5 on the right side of the planetary gear mechanism; the second sun gear 6 on the right side of the planetary gear mechanism; the first planetary carrier 7 on the right side of the planetary gear mechanism; planetary gear The first planetary gear 8 on the right side of the mechanism; the first sun gear 9 on the right side of the planetary gear mechanism; the first sun gear 10 on the left side of the planetary gear mechanism; the first ring gear 11 on the left side of the planetary gear mechanism; the second planet on the left side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com