Full-automatic electronic control hydraulic moving train set

An electronically controlled hydraulic and train set technology, which is applied to motor vehicles, locomotives, railway vehicles, etc., can solve problems such as waste of manpower and material resources, large investment, and potential safety hazards, and achieve the effects of reducing strength, improving operating efficiency, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

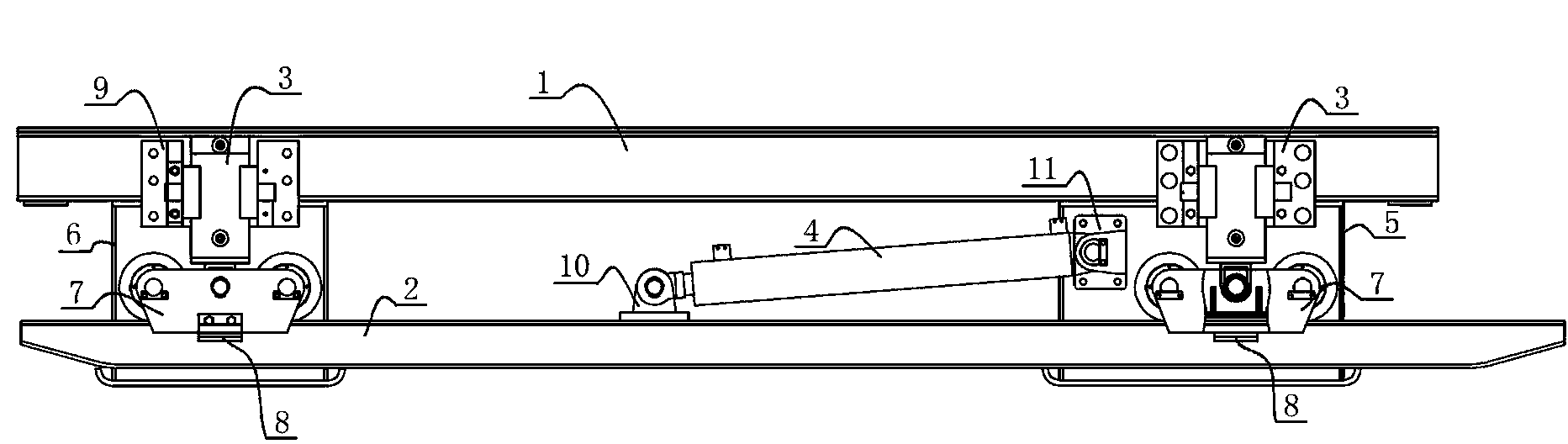

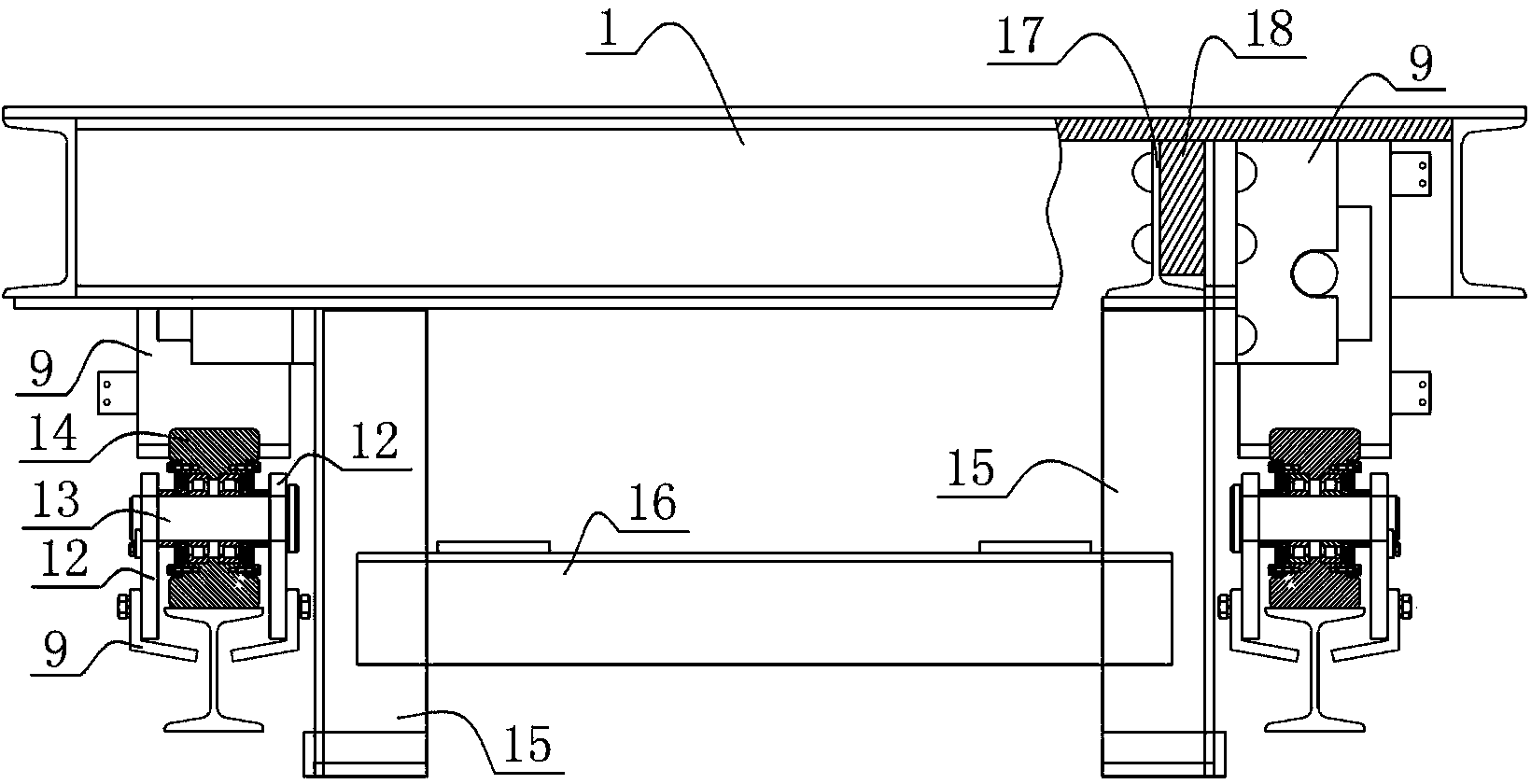

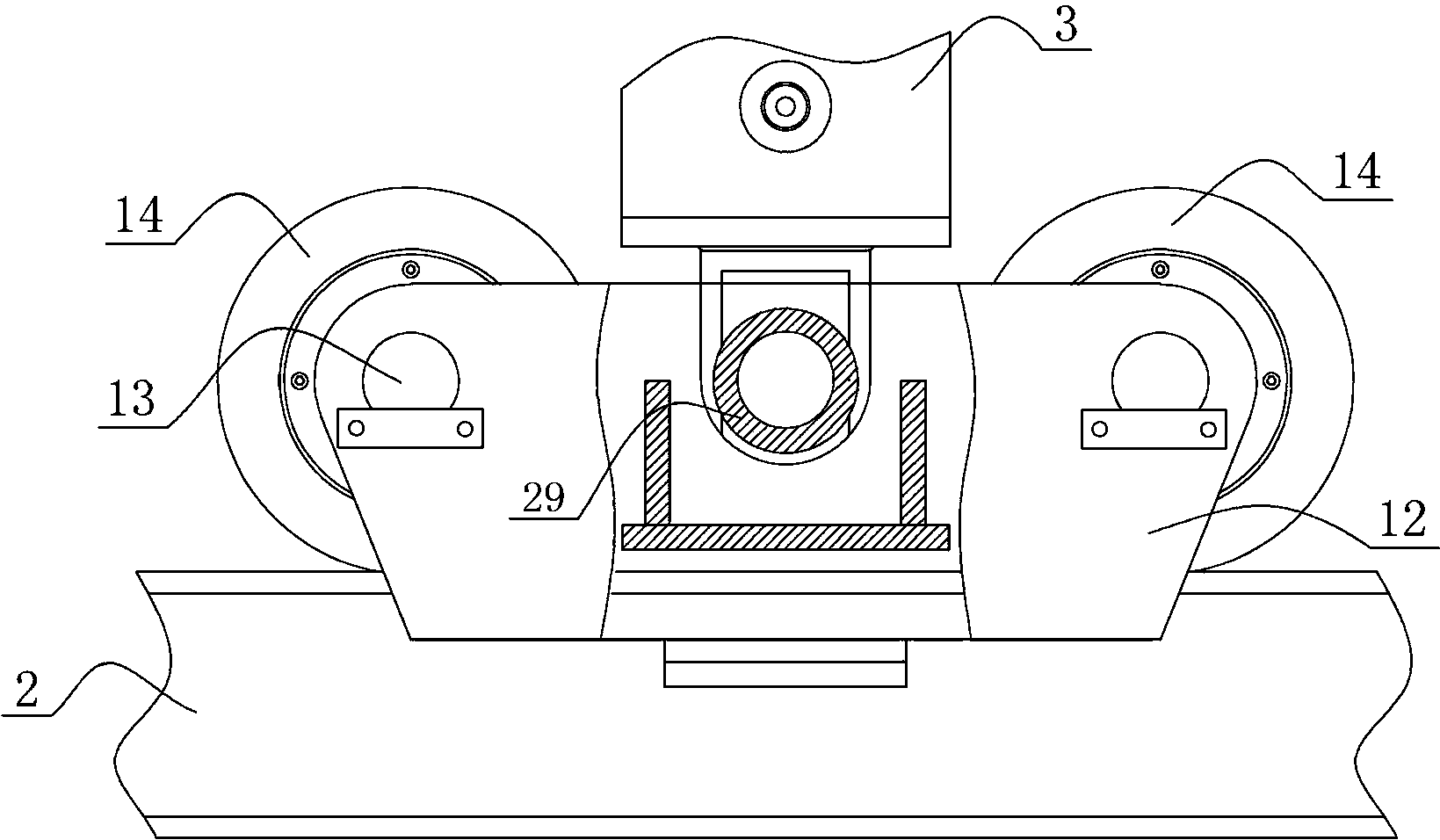

[0025] Such as figure 1 and figure 2 As shown, the front view and the left view of the fully automatic electronically controlled hydraulic mobile train set of the present invention are provided, which include a mobile platform 1, a walking track 2, a lifting hydraulic cylinder 4, a front support 5, a rear support 6, and a sliding wheel mechanism 7 , track hanging plate 8, oil cylinder support seat 9, first ear seat 10, second ear seat 11; the mobile platform 1 shown plays a role of fixing and supporting, and is used to carry fully mechanized mining equipment in mines, and the two sides below the mobile platform 1 All are equipped with walking tracks. The four corners of mobile platform 1 are all provided with lifting hydraulic cylinder 3, and lifting hydraulic cylinder 3 is fixed on the mobile platform by oil cylinder support base 9, and the front en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com