A wheel hub lifting jig

A hoisting and jig technology, applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problems of uneven heating and cooling of the hub, large time gap, limited size of the hub, etc., to avoid deformation problems, increase the safety factor, increase the The effect of high friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

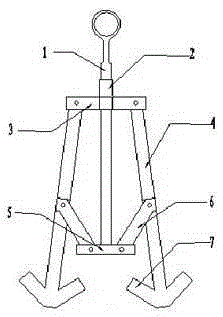

[0018] A hub hoisting jig mainly includes a suspension shaft 1, a sleeve 2, a square plate 3, a mechanical arm 4, a weight 5, a connecting rod 6, and an anchor-shaped manipulator grip 7, wherein the suspension shaft 1 is located in the sleeve 2 and can be Move up and down, the sleeve 2 is welded to the center of the square plate 3, the lower end of the suspension shaft 1 is welded to the weight 5, the mechanical arm 4 is connected to the side of the square plate 3 through pins, and the end of the connecting rod 6 is connected to the weight 5 through the pins. The other end is rotationally connected with the mechanical arm 4, and the anchor-shaped manipulator grip 7 is welded to the lower end of the mechanical arm 4, wherein the mechanical arm 4, the connecting rod 6 and the square plate 3 are made of triangle iron, and the anchor-shaped manipulator grip 7 is made of square steel pipe The size of the weight 5 is much smaller than the size of the square plate 3. The limit positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com