Outward-wrapped-type anti-collision guardrail formwork reinforcing structure

A technology for strengthening anti-collision guardrails and templates, which is applied to bridge parts, bridges, buildings, etc., can solve problems such as the difficulty of reinforcing outsourced anti-collision guardrail templates, and achieve the effect of solving reinforcement difficulties and ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

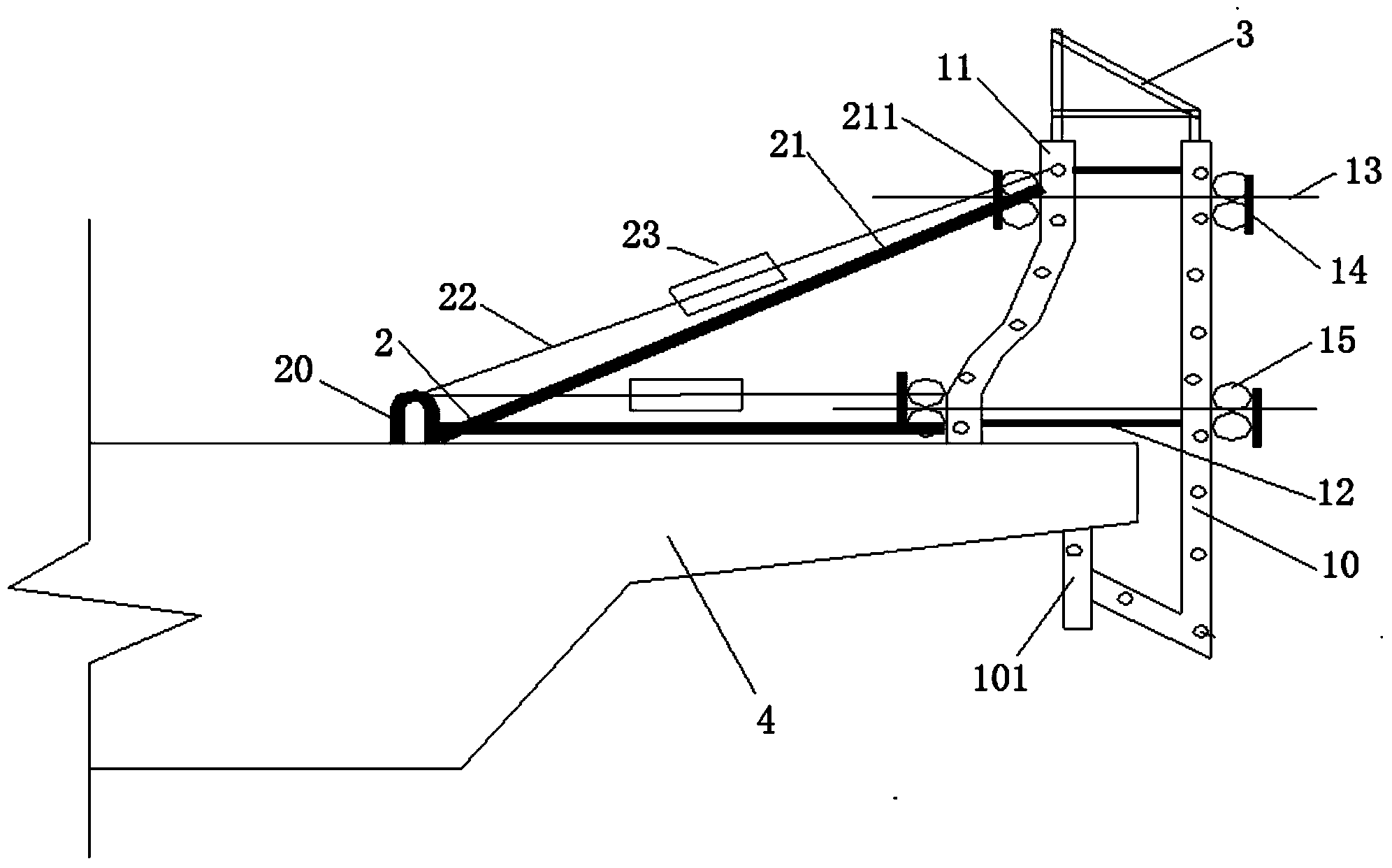

[0012] Such as figure 1 As shown, the outsourcing anti-collision guardrail formwork reinforcement structure, the formwork 1 is installed on the side of the bridge 4, the formwork 1 includes the outer formwork 10 and the inner formwork 11, the longitudinal section of the outer formwork is L-shaped, the bottom of the outer formwork is bent towards the bottom plane of the bridge and Supported on the bottom plane of the bridge by a foot 101, the longitudinal section of the inner formwork is in the shape of a broken line, the bottom surface of the inner formwork is supported on the upper plane of the bridge, and a top rib 12 is provided between the outer formwork and the inner formwork for support and a tie rod 13 Tightening, the upper plane of the bridge is equipped with a puller 2 inside the inner formwork, the puller includes a support frame 21, the support frame is clamped by the bottom side and the upper side to form an acute angle, and the bottom side and the upper plane of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com