Overhead heightening device skeleton filling type reinforcing method

A filling and skeleton technology, applied in the field of skeleton filling reinforcement of overhead devices, can solve the problems of difficult reinforcement of devices and damage to pipe legs, and achieve the effect of reducing reinforcement weight, strong plasticity, and inhibiting glue flowing and contaminating printed boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

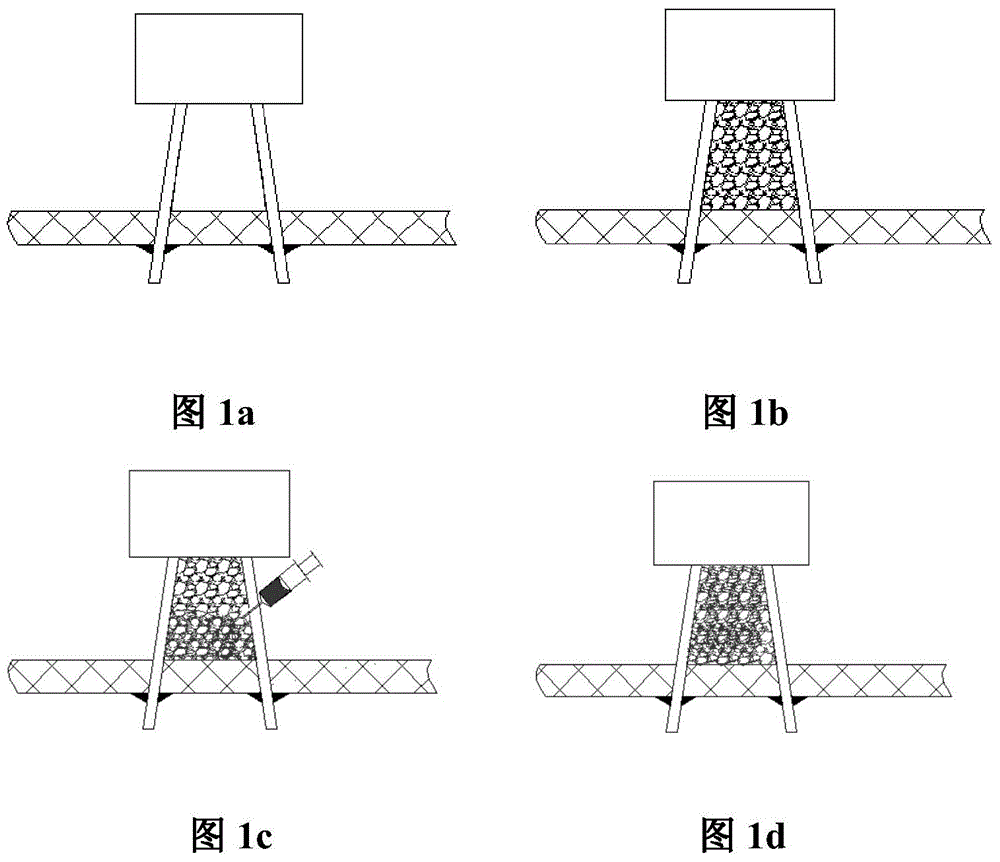

[0055] see figure 1 , is a schematic diagram of the adhesive reinforcement process for a small overhead device, and the specific reinforcement process is:

[0056] 1. Fill and reinforce the space of the device according to the needs of the skeleton, such as figure 1 a, for measurement, choose 20 times the expansion ratio, and the density is 50KG / m 3 , 6mm thick polyethylene foam, cut out a 6mm high, 4mm wide, and 5mm long filler skeleton that fits the space at the bottom of the capacitor.

[0057] 2. Clamp and compress the foam skeleton with tweezers, and fill the space when it is sent into the device, such as figure 1 b, Confirm that the tailored foam skeleton fills the space at the bottom of the device.

[0058] 3. After filling the space to be filled, select acrylic electronic glue with a viscosity of 1700cps, and use a glue injector to infiltrate the foaming skeleton, such as figure 1 c.

[0059] 4. After soaking, let it stand at room temperature for 12 hours until th...

Embodiment 2

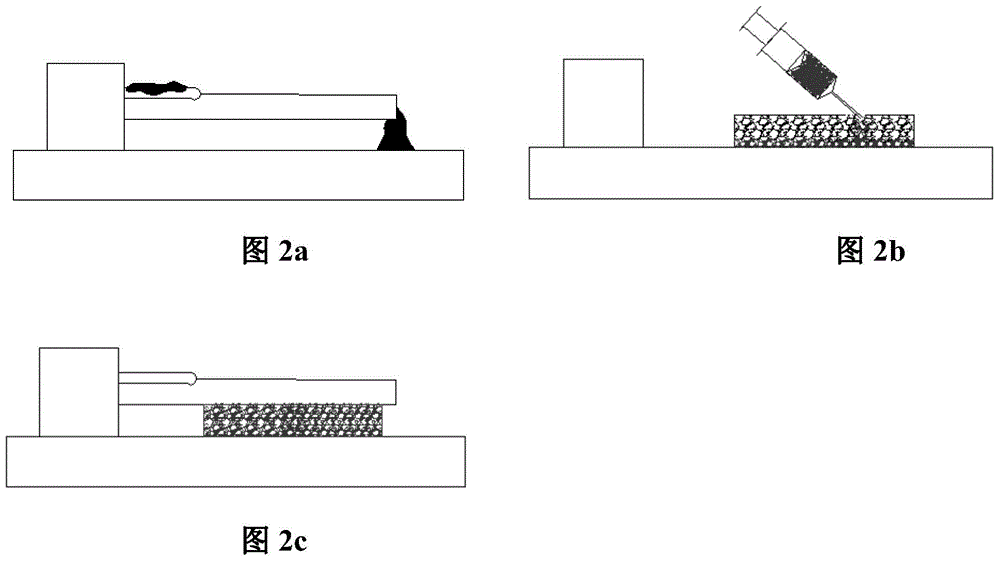

[0061] see figure 2 , is a schematic diagram of the process of bonding and strengthening the memory stick and the ETX module with a foam skeleton. The specific strengthening process is:

[0062] 1. In the CPU assembly of a computer, the memory stick and ETX need to be inserted into the card slot for assembly, and the memory stick is fastened on the computer motherboard by means of a spring; the spring is loose and other unreliable factors in the complex mechanical application environment. At present, there is no solution For such problems, it is generally used to directly bond the memory stick to the motherboard or the circlip with a relatively viscous electronic glue, such as figure 2 a; After this method is directly bonded, the electronic glue will pollute the printed board assembly when bonding, and because the direct bonding uses a more rigid glue, the stress release is large, and the maintenance performance is reduced, which cannot meet the needs of product development....

Embodiment 3

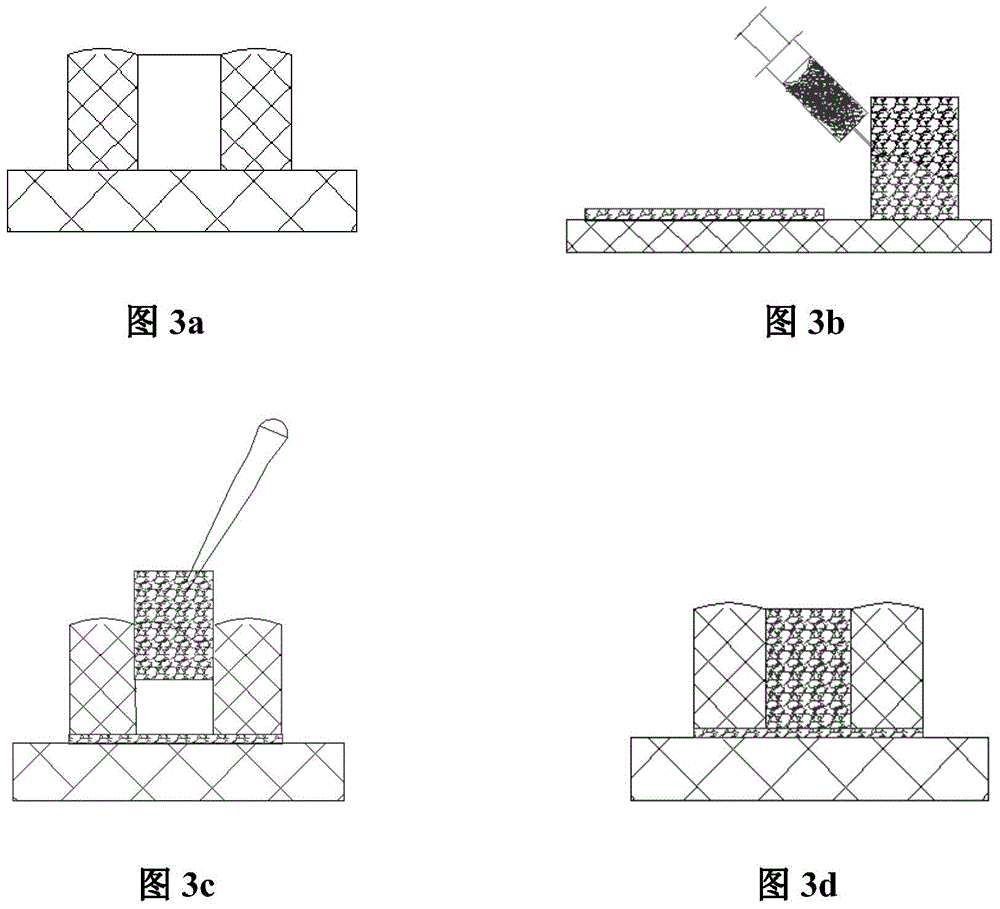

[0067] see image 3 , is a schematic diagram of the structure of a transformer coil filled with a foam skeleton, and the specific reinforcement process is as follows:

[0068] 1. The transformer coil of a certain type of product is a hollow structure, such as image 3 a. To avoid damage to the coil caused by the harsh mechanical environment during the use of the coil, it is generally reinforced by embedding with potting glue. This embedding method is not good for the heat dissipation of the coil, and it is easy to cause the coil to overheat and burn, and the coil has lost maintainability.

[0069] 2. Use the method of foaming skeleton filling, according to the inner diameter of the coil, choose 10 times the foaming multiple, and the density is 100KG / m 3 , Polyethylene foam with a thickness of 6mm, cut out a cylinder with a diameter of 4mm and a height of 6mm. The bottom is filled with the same diameter as the outer diameter of the coil with a 4mm thick foam skeleton.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com