A construction method of hangar concrete surface structure

A concrete surface and construction method technology, applied in the direction of floors, building structures, buildings, etc., can solve the difficulty of ensuring the flatness and straightness of steel corner protection, the difficulty of installing and reinforcing steel corner protection, and the complicated construction process of steel corner protection and other problems, to achieve the effect of solving the difficulties of installation and reinforcement, saving layout and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

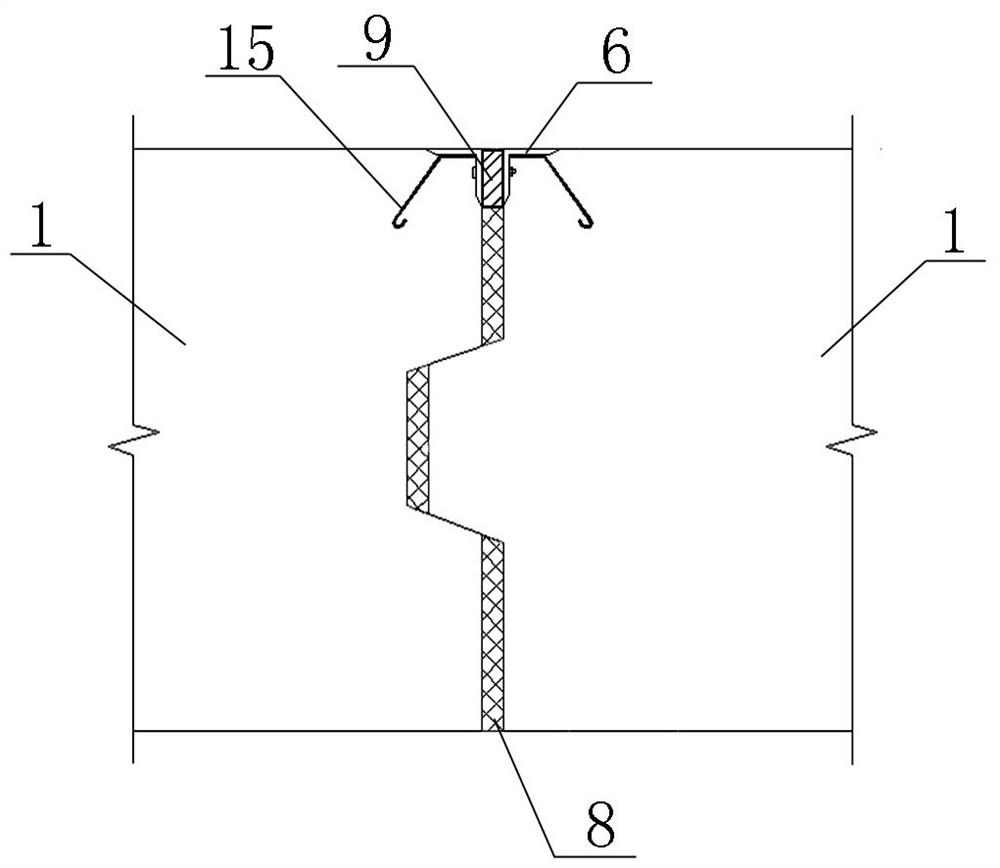

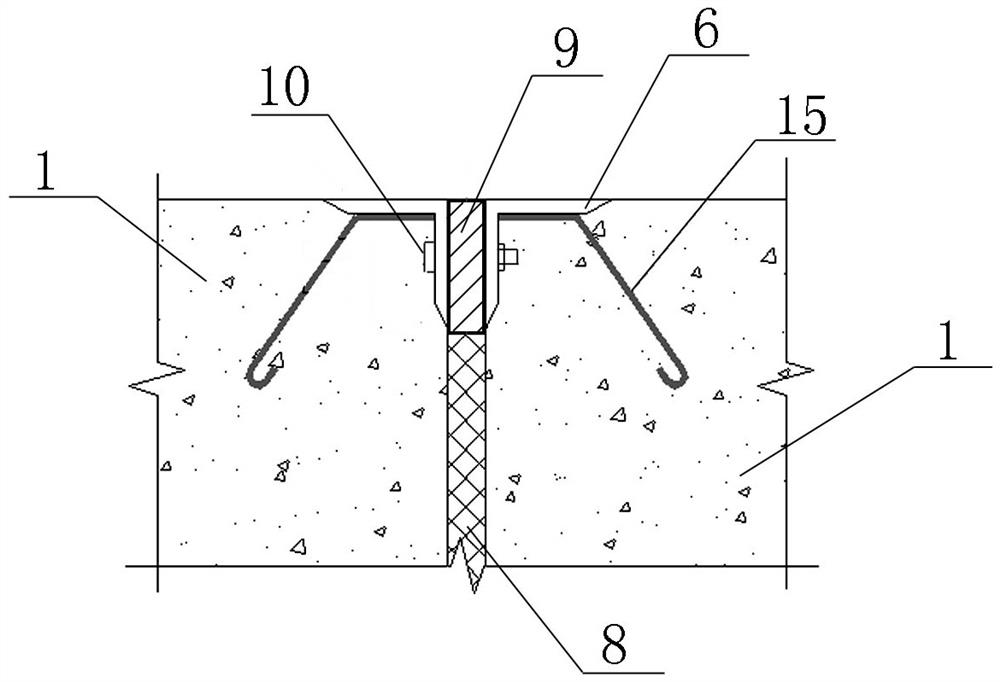

[0045] This embodiment is designed for a 400mm thick concrete ground steel formwork and angle steel angle protection system in a certain project. The longitudinal side form is used to connect the steel angle protection 6 with bolts 10 to solve the technical problem of difficult installation and reinforcement of the steel angle protection 6, and The flatness and straightness of the steel corner protector 6 are guaranteed, and the construction process of the steel corner protector 6 is simplified at the same time, and the construction progress is accelerated.

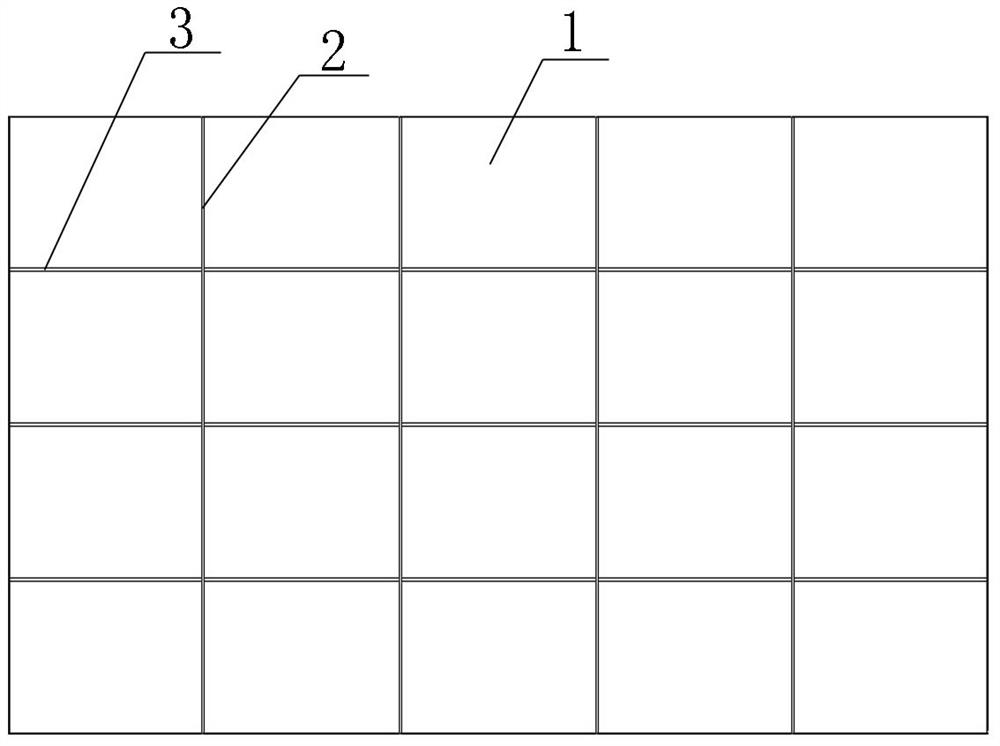

[0046] like Figure 1-4As shown, the hangar concrete surface structure includes a concrete unit block 1; the concrete unit block 1 is formed by casting in-situ, and the concrete unit block 1 has one group, which is arranged in a matrix; the horizontally adjacent concrete unit blocks 1 are separated by longitudinal partitions 2; vertically adjacent concrete unit blocks 1 are separated by transverse partitions 3; the side o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com