Freezing and in-hole grouting improved combined bearing stratum reinforcement scheme

A grouting and solution technology, which is applied to earth-moving drilling, underground chambers, and shaft equipment, etc., can solve the problems of high water content, high risk and poor stability in water-rich soft soil strata, so as to improve construction safety, The effect of increased load-carrying capacity, increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

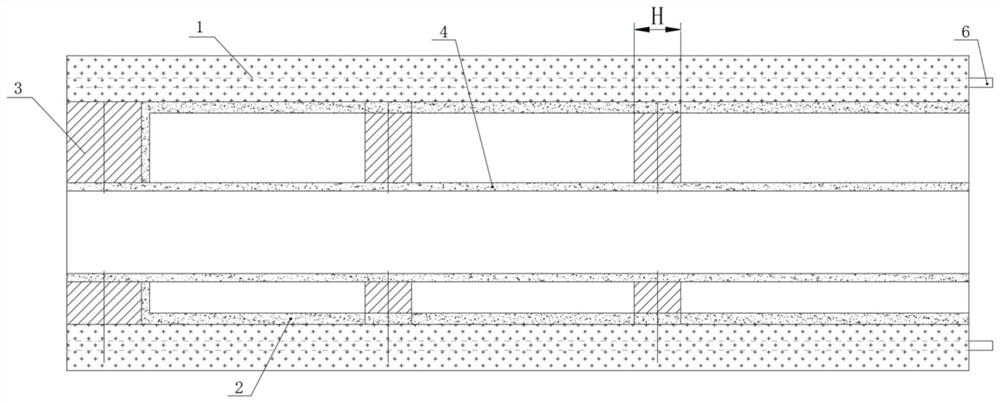

[0030] In this embodiment, the combined load-bearing stratum reinforcement scheme improved by freezing and grouting in the hole is used to extend a large horseshoe-shaped tunnel on a shield tunnel that has been constructed in a turnout crossing section of a certain subway tunnel. Specifically, Proceed as follows:

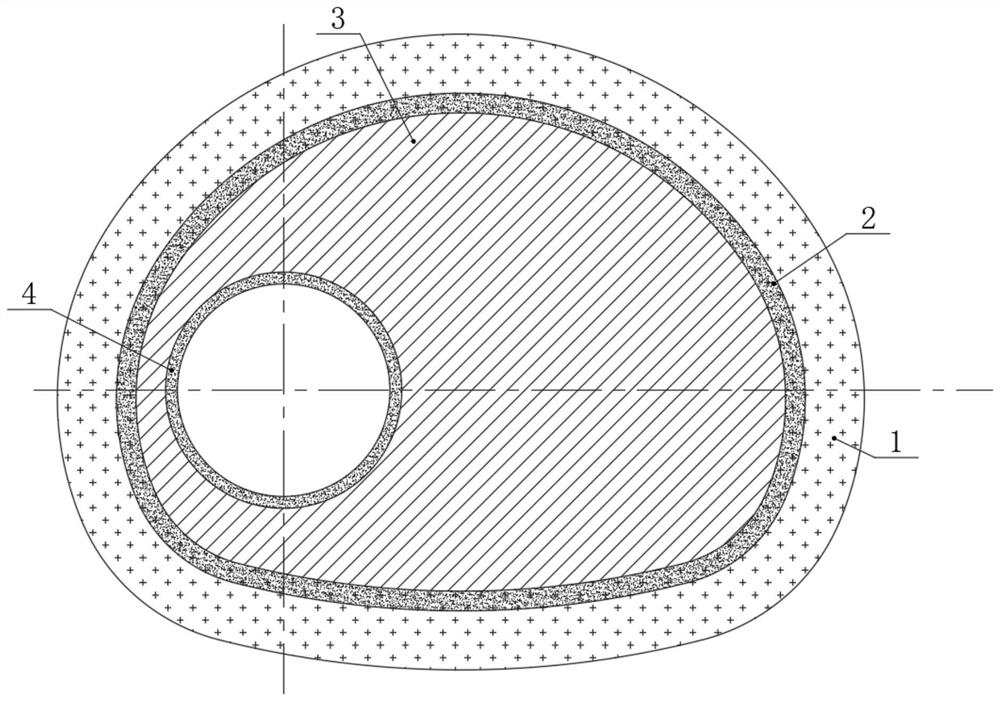

[0031] Step A: the underground tunnel 2 is planned to be constructed according to the existing tunnel 4, and the underground tunnel 2 is planned to be a horseshoe shape, and according to the form of the underground tunnel 2 to be constructed, the frozen wall 1 is designed at the outer layer of the underground tunnel 2 to be constructed;

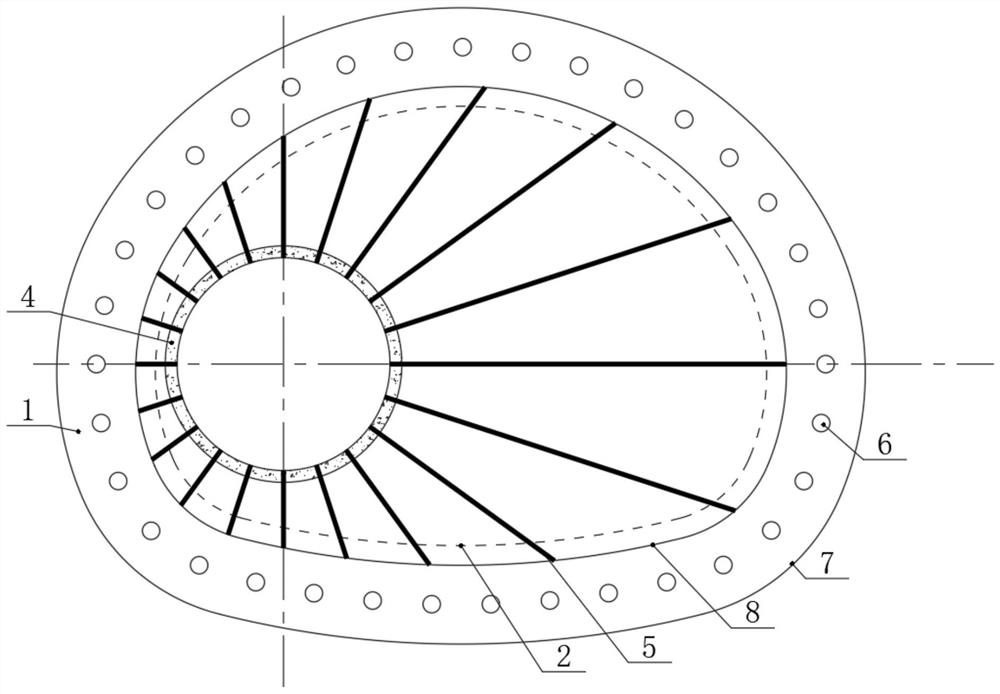

[0032] Step B: Insert the freezing tube 6 at the position of the designed freezing wall 1; the freezing tube 6 is located on the cross-sectional geometric center of the outer boundary 7 of the freezing area and the inner boundary 8 of the freezing area of the designed freezing wall 1:

[0033] Step C: According to the shape of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com