Snow blower for cleaning ice and snow on road

A snow-clearing vehicle and snow-clearing technology, which is applied to snow surface cleaning, cleaning methods, construction, etc., can solve the problems of low work efficiency and slow cleaning speed, and achieve the effects of simple structure, prolonging service life and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

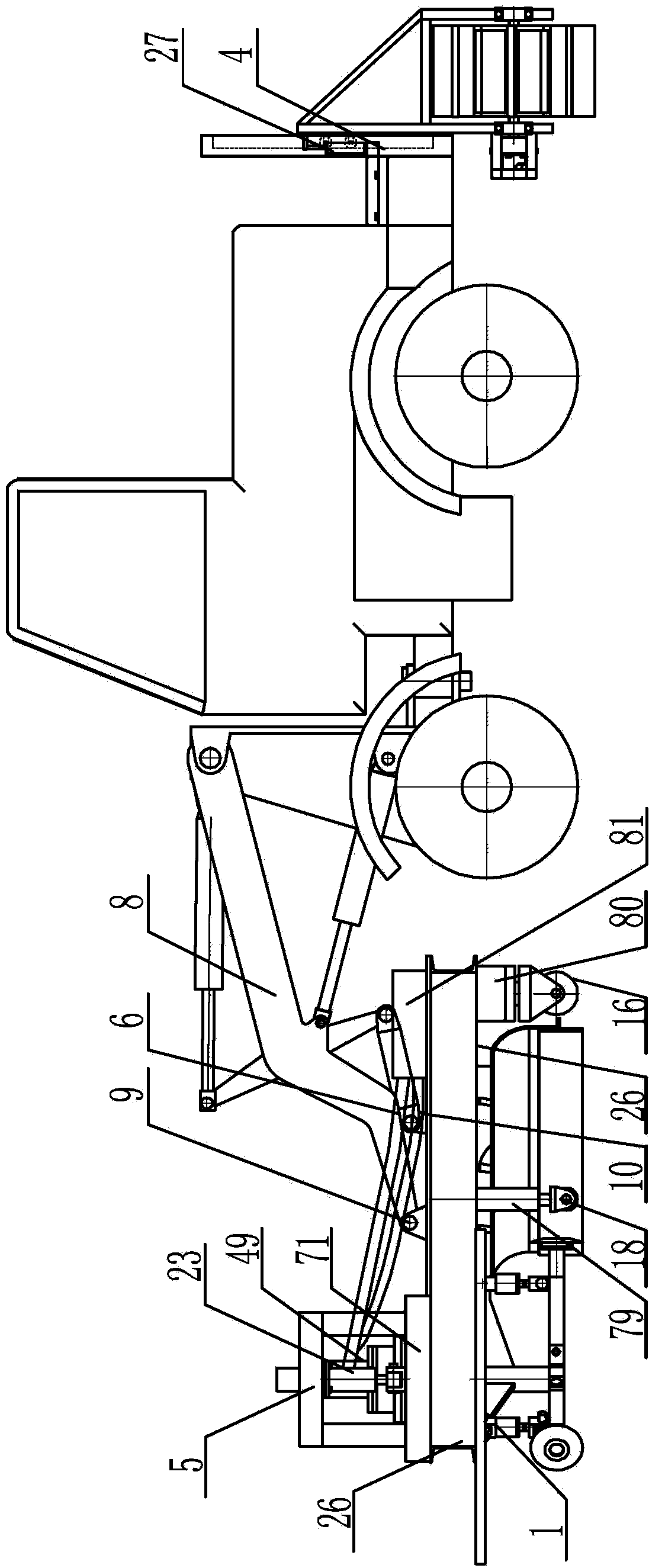

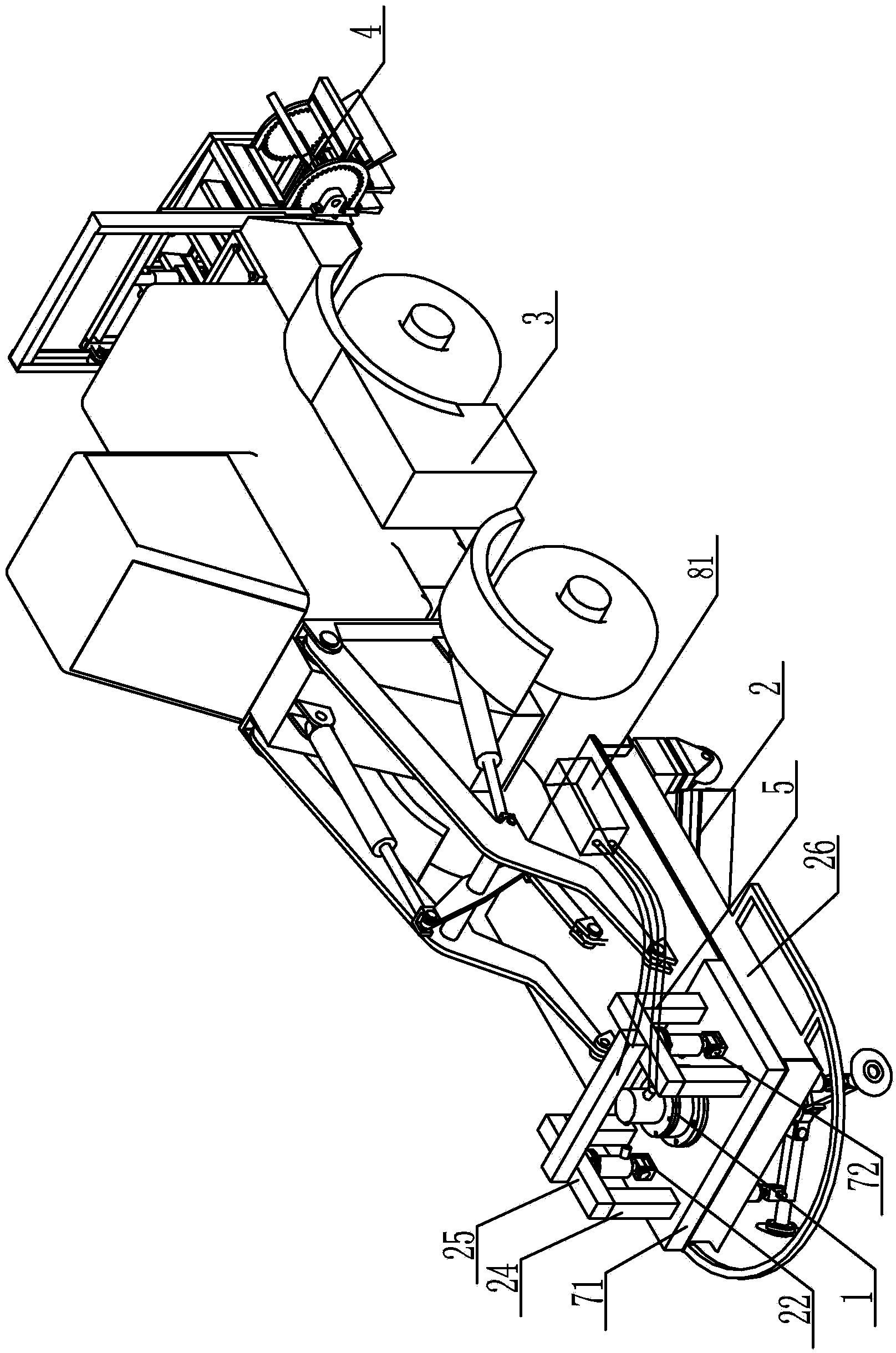

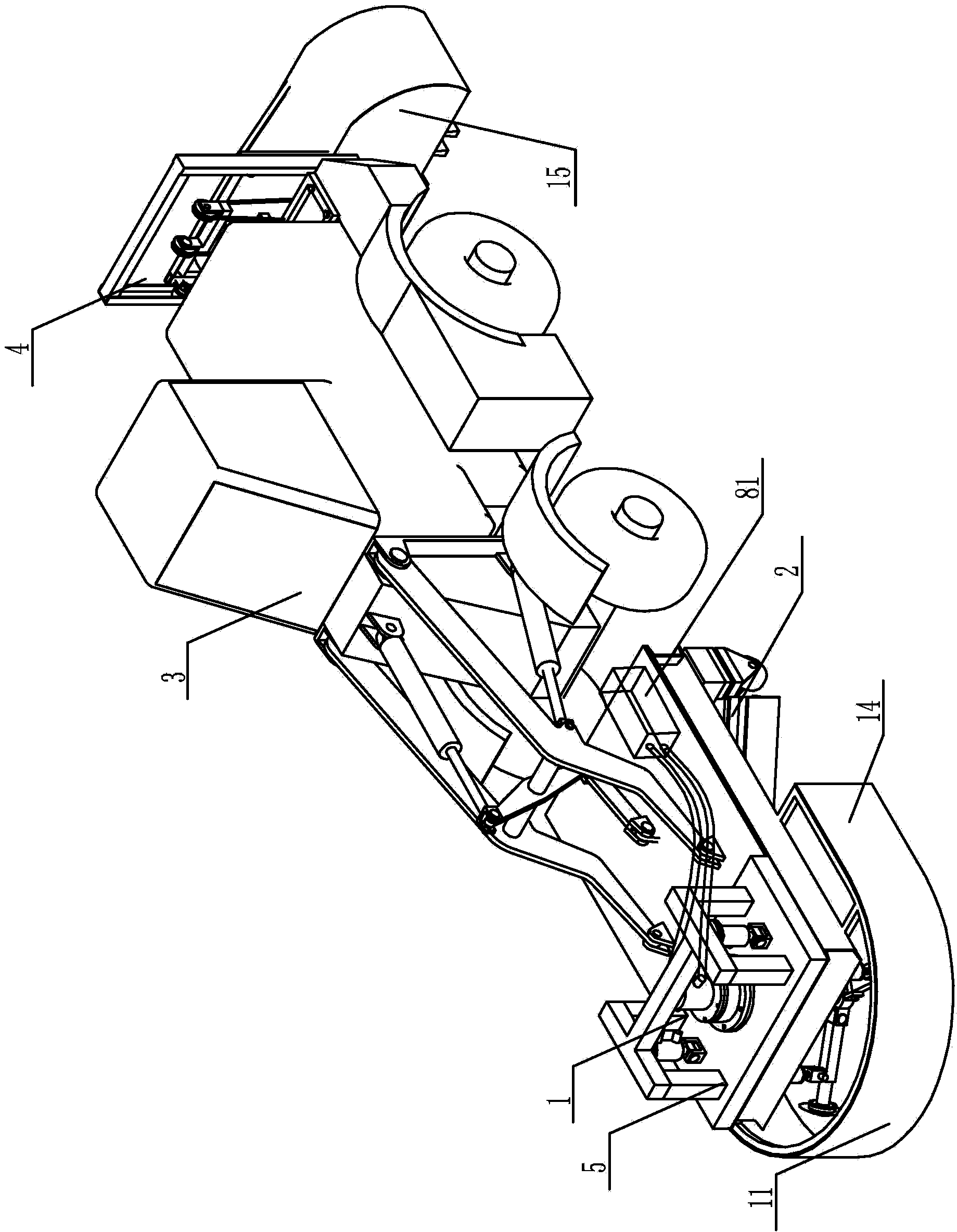

[0007] Specific implementation mode one: combine Figure 1-Figure 13 Describe this embodiment, the snow removal vehicle for clearing ice and snow on the road in this embodiment, the snow removal vehicle includes a snow removal vehicle body 3, the snow removal vehicle also includes an ice breaker assembly 1, an ice scraper assembly 2, profiling cleaner assembly 4, ice breaker connection assembly 5, frame body 26 and power hydraulic controller 81, ice breaker connection assembly 5 includes ice breaker mounting seat 71, two oil cylinder connection seat pins 72, two A crossbeam 25, two oil cylinder connecting seats 22, two lifting oil cylinders 23 and four columns 24, the extended end of each lifting oil cylinder 23 is installed on the oil cylinder connecting seat 22 through the oil cylinder connecting seat pin 72, and the icebreaker assembly 1 Installed on the ice breaker mounting base 71, the ice breaker mounting base 71 is installed on the left end of the frame body 26, and the...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination Figure 1-Figure 5 Describe this embodiment, the snow removal vehicle for clearing ice and snow on the road in this embodiment, the ice breaker assembly 1 includes an ice breaker hydraulic motor 49, a universal joint 54, a rotary cutter shaft 56, and two connecting flanges 69 , N shock absorbing support arms 53, N hob cutter bar shafts 58, N rolling bearings 59, N hob cutters 60, N cutter bar fixing ears 61, N shock absorbing mechanisms 74, multiple first connections 17, a plurality of fifth connecting parts 52 and a plurality of pin shafts 57, the ice breaker hydraulic motor 49 includes a fixed connection sleeve 50, a transmission rotary body 70, two rolling bearings 55, and a rolling bearing 59 is installed in each hob 60 A connection flange 69 is installed at both ends of the universal joint 54, the universal joint 54 is vertically arranged, the connection flange 69 at the top of the universal joint 54 and the output end ...

specific Embodiment approach 3

[0009] Specific implementation mode three: combination Figure 1-Figure 3 and Figure 13 This embodiment is described. The snow removal vehicle for clearing ice and snow on the road in this embodiment, the ice breaker assembly 1 includes an ice breaker hydraulic motor 49, a rotary cutter shaft 56, two connecting flanges 69, and N shock absorbers Support arm 53, N hob cutter bar shafts 58, N rolling bearings 59, N hob cutters 60, N cutter bar fixing ears 61, N shock absorbing mechanisms 74, multiple fifth connectors 52 and multiple Pin shaft 57, a rolling bearing 59 is installed in each hob 60, a connecting flange 69 is fixedly installed on the output end of the transmission rotary body 70 of the hydraulic motor 49, and the rotary cutter shaft 56 is vertically arranged below the rotary body 70, and the rotation The input end of the cutter shaft 56 is fixedly installed with a connecting flange 69, and the two connecting flanges 69 are fixedly connected through a plurality of fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com