A large-scale forging machinery photoelectric protection safety device

A photoelectric protection and forging technology, applied in the field of forging machinery, can solve the problems of fatigue operation, unavailability, brewing tragedy, etc., and achieve the effect of effective safety guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

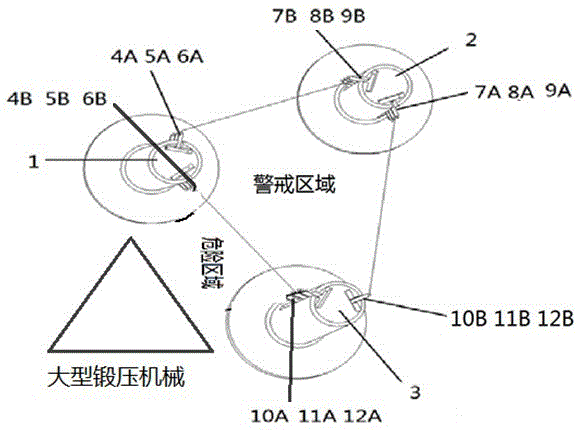

[0015] Judging the alert area of large forging machinery based on theoretical data, such as figure 1 As shown, the three installation columns 1, 2, 3 are respectively erected on the same side of the forging machine, and the three installation columns 1, 2, 3 are arranged in a triangle to form a triangular warning area.

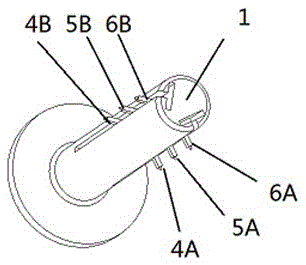

[0016] Such as figure 2 , 3 As shown, there are two rows installed on the mounting column 1, each row of three photoelectric sensor switches, one row is 4A, 5A, 6A, and the other row is 4B, 5B, 6B.

[0017] Two rows are installed on the mounting column 2, each row of three photoelectric sensor switches, one row is 7A, 8A, 9A, and the other row is 7B, 8B, 9B.

[0018] Two rows are installed on the mounting column 3, each row of three photoelectric sensor switches, one row is 10A, 11A, 12A, and the other row is 10B, 11B, 12B.

[0019] After installing the positions of the three mounting columns 1, 2, and 3, adjust the nine pairs of photoelectric sensor swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com