Separate-type nozzle design method for big-bypass-ratio engines

A technology of engine nozzle and large bypass ratio, which is applied in computing, special data processing applications, instruments, etc., and can solve problems such as reduced nozzle performance, sudden changes in speed and pressure, and discontinuous curvature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

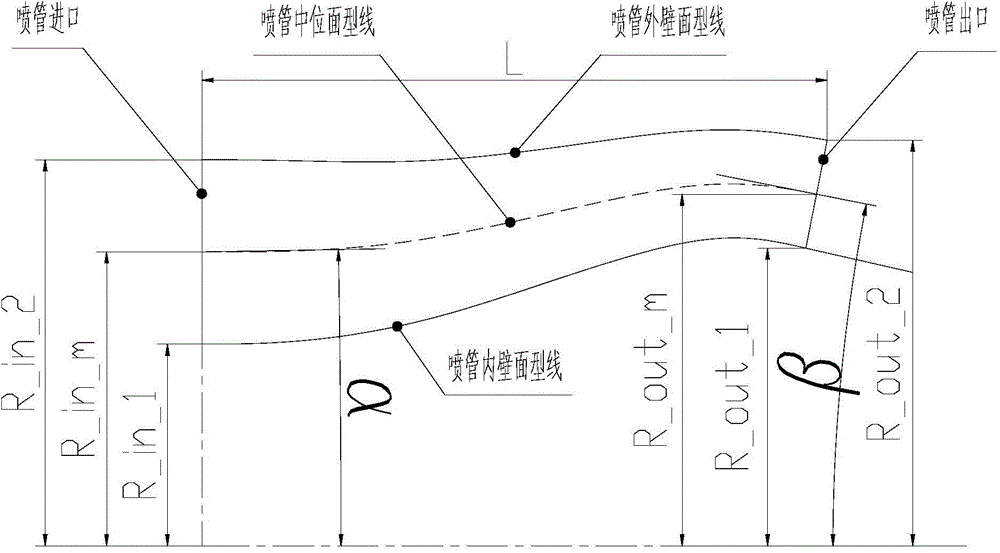

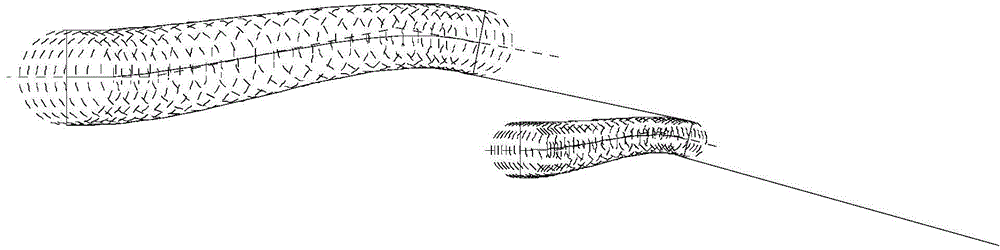

[0039] This embodiment provides a design method for a split nozzle of a large bypass ratio engine, which is characterized in that: a design method for a split nozzle of a large bypass ratio engine, and the aerodynamic design method for a large bypass ratio engine nozzle is suitable for large bypass ratios Compared with the design of the inner nozzle and the outer nozzle in the split nozzle of the engine.

[0040] Using parametric design, the nozzle wall is constructed with a smooth and continuous curve, and the area change along the nozzle is determined by using a reasonable change law of the area along the convergence section. The specific process is as follows:

[0041] Step 1 for defining the initial parameters of nozzle aerodynamic design and assigning values;

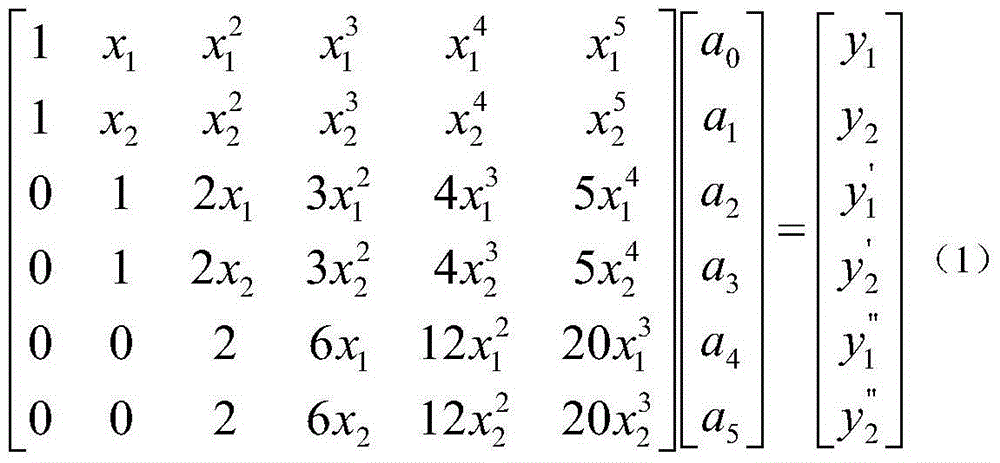

[0042] Step 2 for solving the profile line of the plane in the nozzle;

[0043] Step 3 for solving the law of area change along the nozzle;

[0044] Step 4 for solving the molded lines of the inner and outer wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com