Intelligent inspection system and inspection method of unmanned aerial vehicle transmission line

A power transmission line and intelligent inspection technology, which is applied in the direction of registration/indication of machine work, instruments, registration/instruction, etc., can solve the problems of easy forgetting and loss, centralized monitoring without drones, and informatization of inspection result data processing and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0205] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

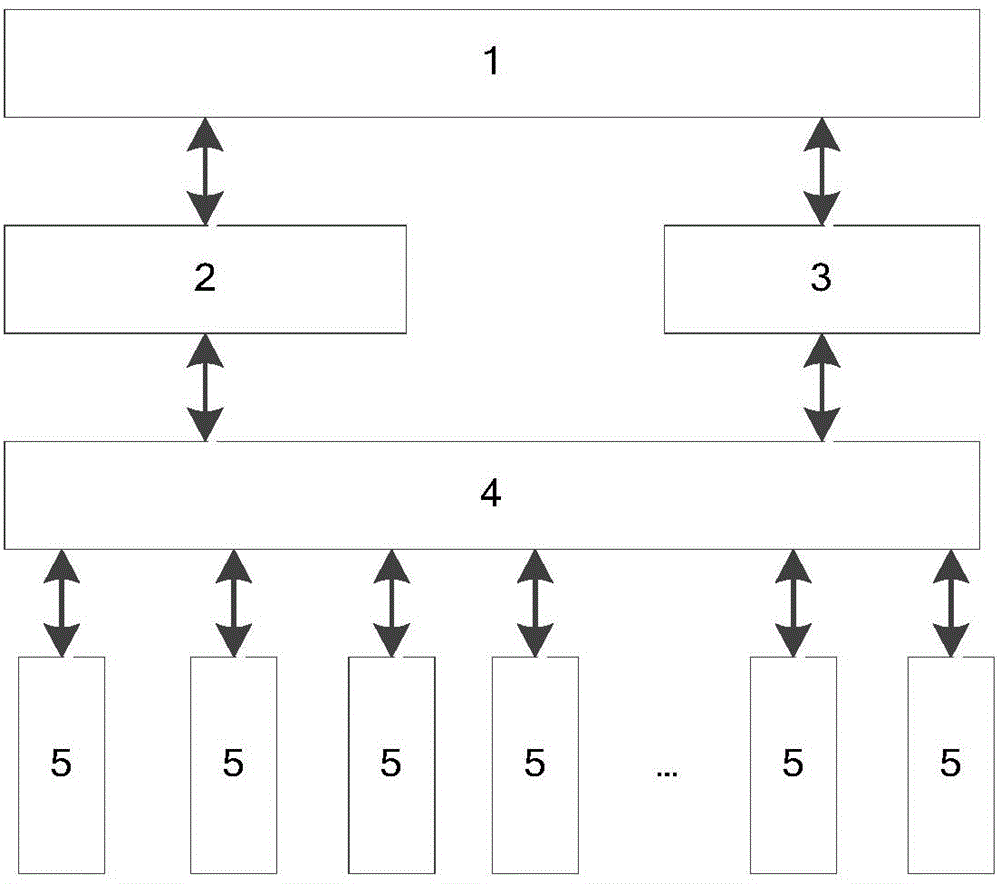

[0206] Such as figure 1 As shown, a UAV transmission line intelligent inspection system includes: inspection task planning system 1, scheduling system 3, monitoring system 4, inspection result processing platform 2 and mobile substation 5; inspection task planning system 1 Communicate with the inspection result processing platform 2 and the dispatching system 3 respectively, the inspection result processing platform 2 and the dispatching system 3 communicate with the monitoring system 4 respectively, and the monitoring system 4 and the mobile substation 5 are connected and communicated in a one-to-many manner;

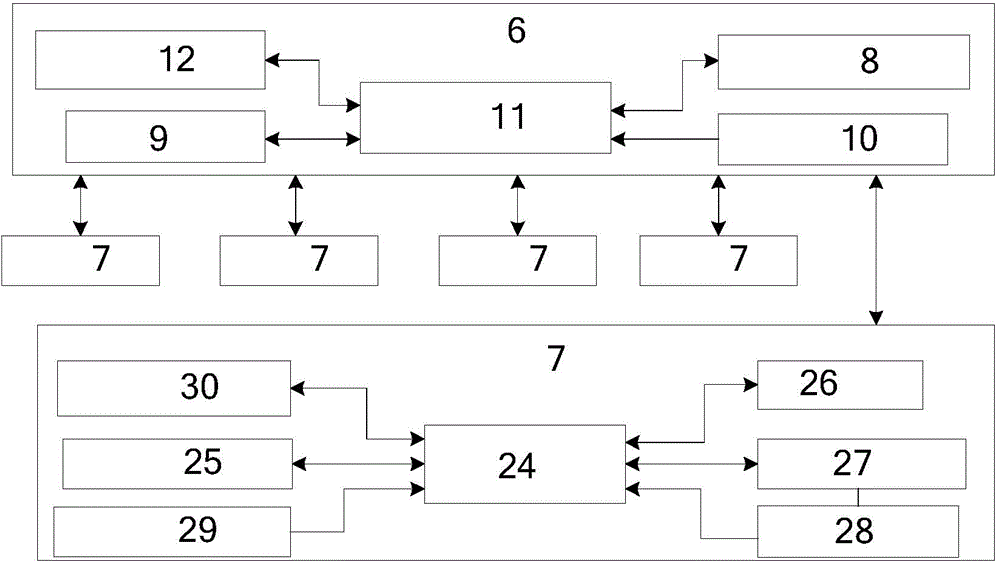

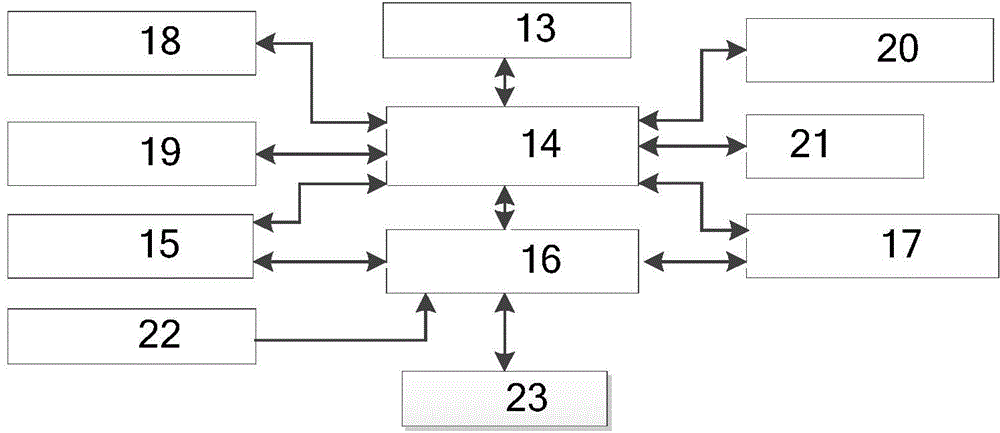

[0207] Such as Figure 2-4 As shown, it is an unmanned aerial vehicle patrol dispatching system, which includes: a dispatching platform 6 and a dispatching terminal 7;

[0208] Among them, the dispatching platform 6 can be connected to one or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com