Five-star chair foot polishing machining system and polishing method applying five-star chair foot polishing machining system

A processing system and a technology of chair legs, which are applied in the field of five-star chair leg polishing methods and polishing processing systems, can solve problems such as low production efficiency, poor working environment, and difficulty in guaranteeing the quality of five-star chair leg grinding and polishing, and achieve improved processing accuracy, The effect of solving limitations and compatibility issues and improving the efficiency of polishing processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

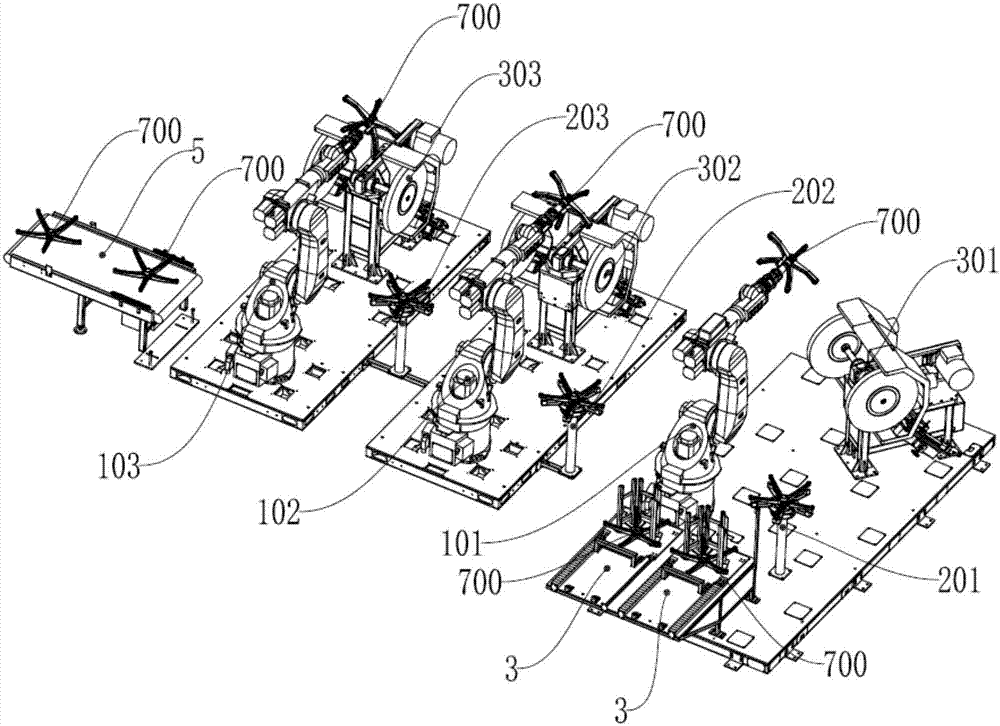

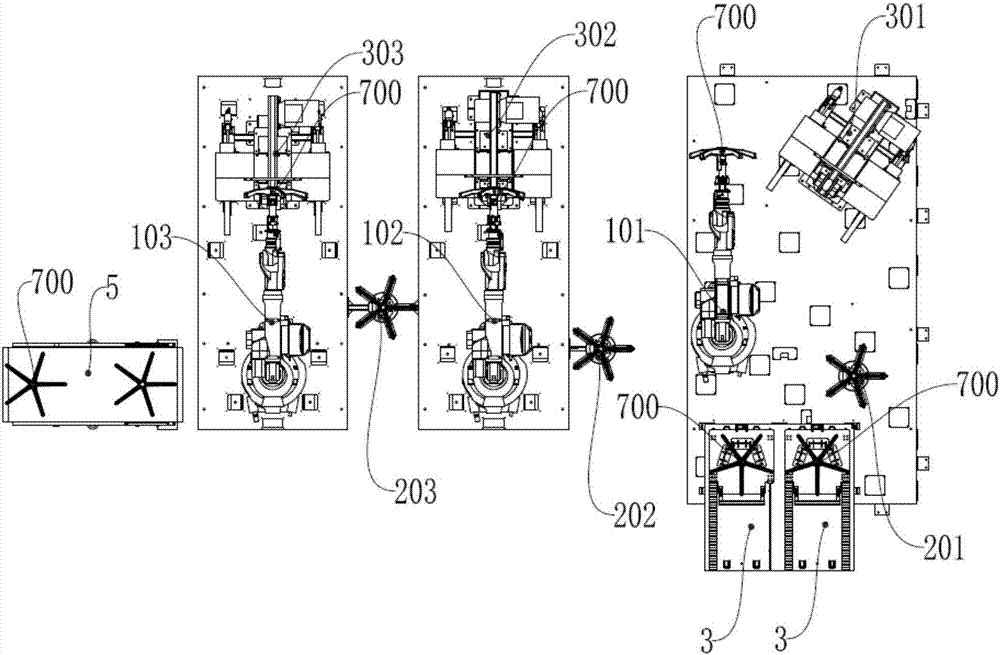

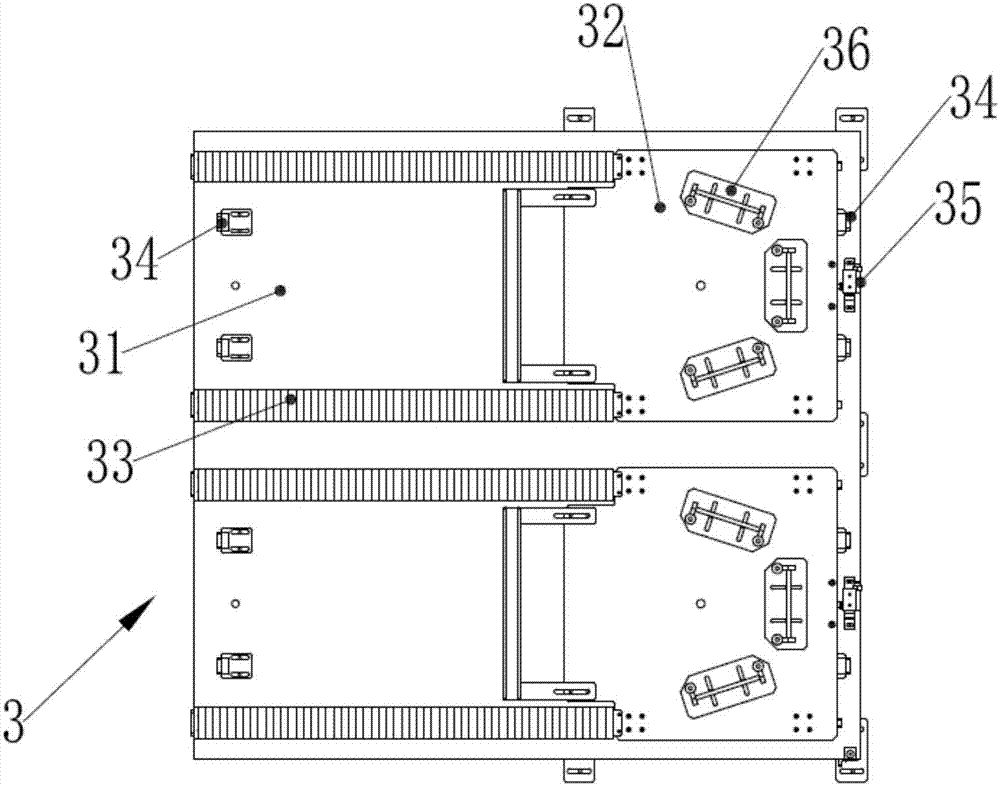

[0051] like figure 1 and figure 2 As shown, a five-star chair foot polishing processing system includes: a feeding device 3, a feeding device 5, a first-level robot 101, a second-level robot 102, a third-level robot 103, a first-level transfer positioning platform 201, and a second-level transfer positioning platform. Positioning table 202, third-level transfer positioning table 203, first-level polishing machine 301, second-level polishing machine 302, and third-level finishing machine 302; the processing system includes a feeding group, a first-level polishing group, and a second-level polishing group in sequence according to the process sequence. Polishing group, three-stage finishing group and blanking group; the feeding group includes the feeding device 3; the discharging group includes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com