Training system for logic control

A logic control and training technology, applied in the field of scientific research, teaching and training systems, can solve the problems of single training projects and difficult to expand, and achieve the effect of ensuring the training effect, easy operation, and stimulating learning interest.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

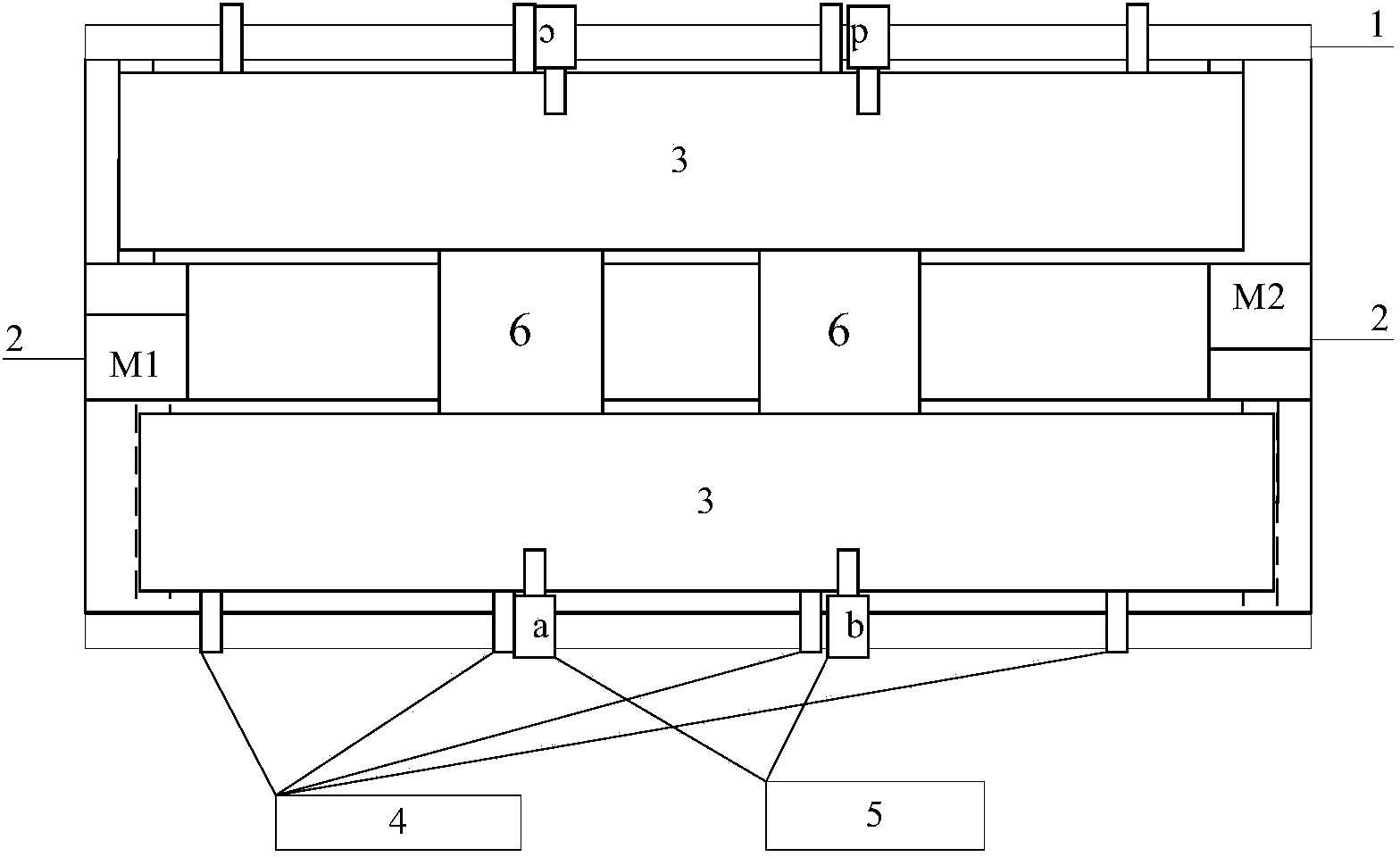

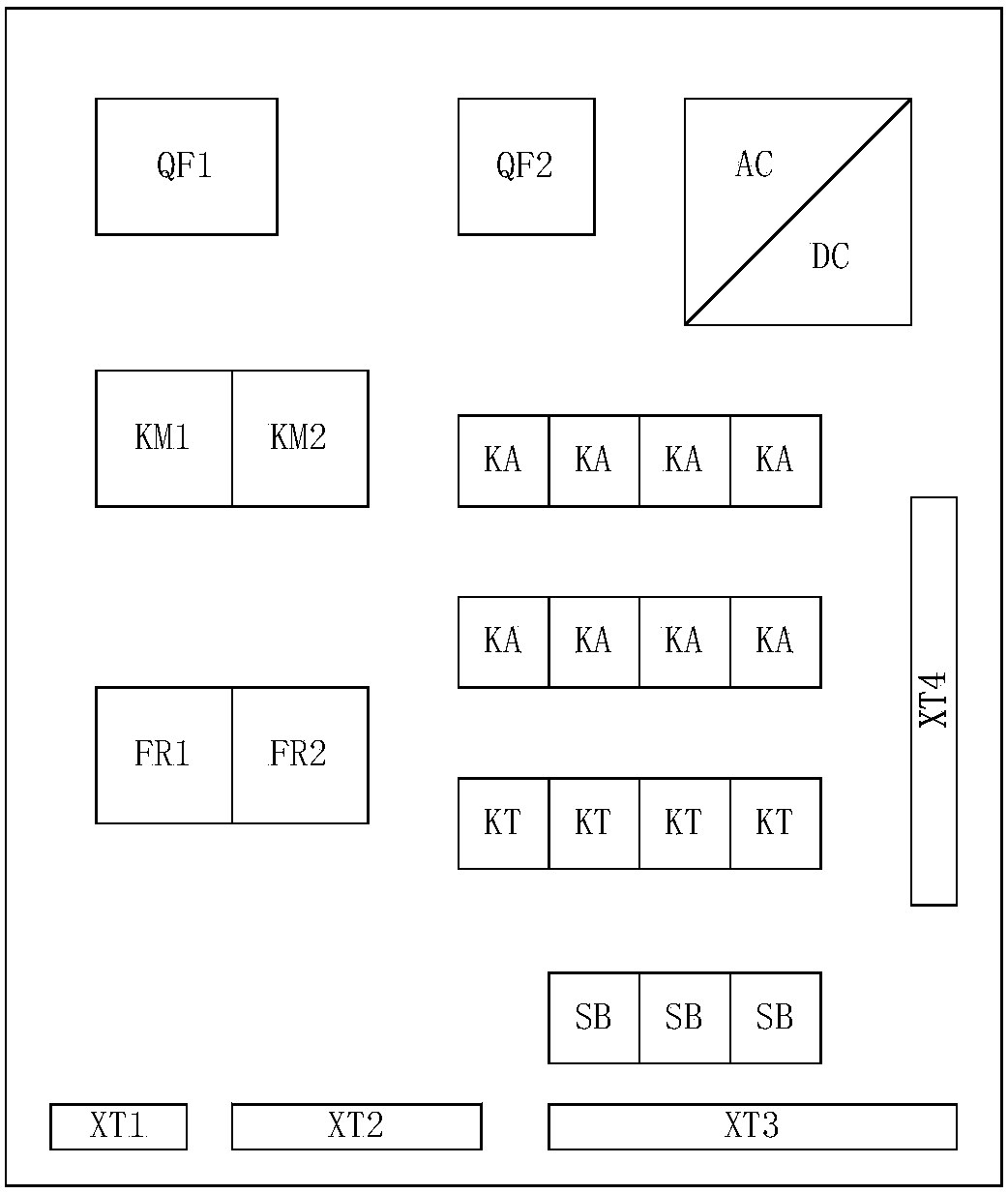

[0021] Embodiment 1: Design and implementation of the three-position round-trip electric control system for the trolley

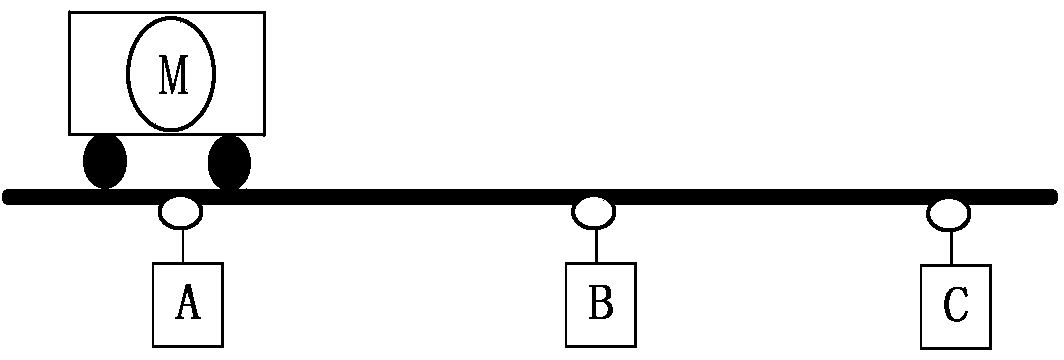

[0022] Task description: Use the relay contactor control method to realize the delayed round-trip control of the trolley position. That is, the car starts from point A, stays at point B for 10 seconds, then continues to move to point C, and stays for another 10 seconds; then reverses back to point B, stays for 10 seconds, and then continues to return to point A and stops. For the task schematic diagram and the car path diagram, see image 3 , Figure 4 .

Embodiment 2

[0023] Embodiment 2: Design and implementation of electrical control system for four-station assembly line

[0024] Task description: Use the relay contactor control method to realize the electrical control of the four-station assembly line of the workpiece. That is, after the workpiece arrives at the feeding port, it is transferred to station 1 through conveyor belt A to stop; after processing at station 1, it is transferred to station 3 through bridge plate A; after processing at station 3, it is transferred to station 1 through conveyor belt B. Station 4 stops; after the processing of station 4 is completed, it is transferred to station 2 through bridge plate B; after station 2 is completed, it is transferred to the discharge port through conveyor belt A to end. For task diagram see Figure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com