driving vehicle

A technology for vehicles and traveling bodies, which is applied in the directions of crawler vehicles, motor vehicles, agricultural machinery and implements, etc., can solve the problems of changes in tilting posture, difficulty in extending the hydraulic cylinder, troublesome manual operation of operating parts, etc., and achieves improved operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

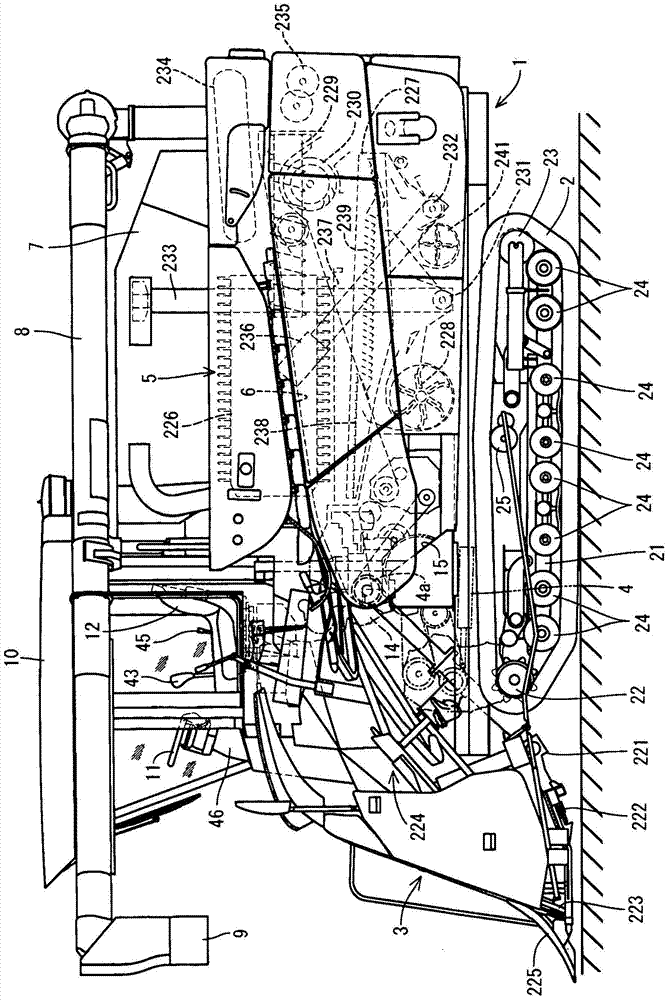

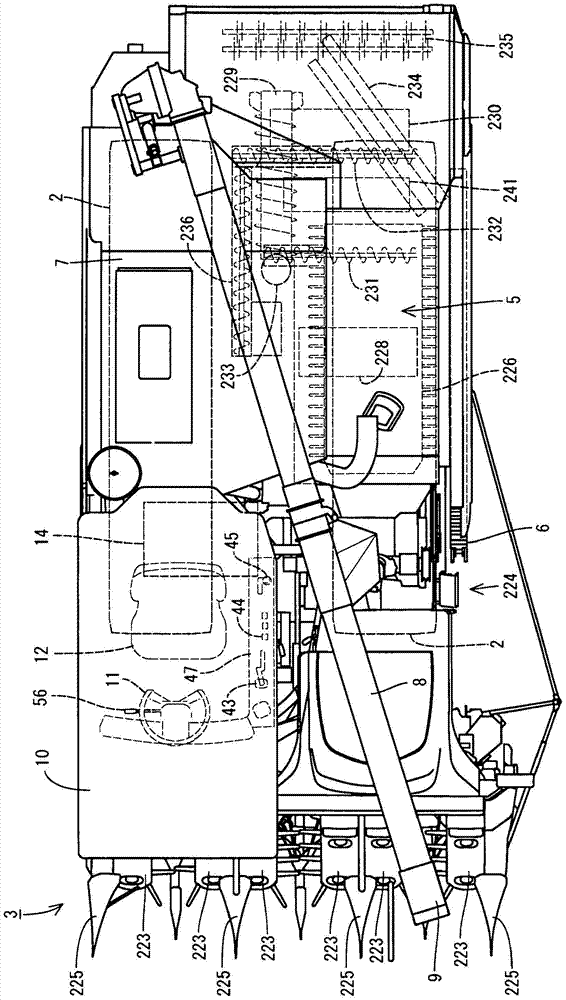

[0068] Next, embodiments embodying the present invention will be described with reference to the drawings. figure 1 is the left side view of the combine harvester, figure 2 It is a top view of the combine harvester. Parameters figure 1 as well as figure 2 , to describe the overall structure of the combine harvester. In addition, in the following description, toward the advancing direction of the traveling body 1, the left side is simply called the left side, and similarly, the right side is simply called the right side toward the advancing direction.

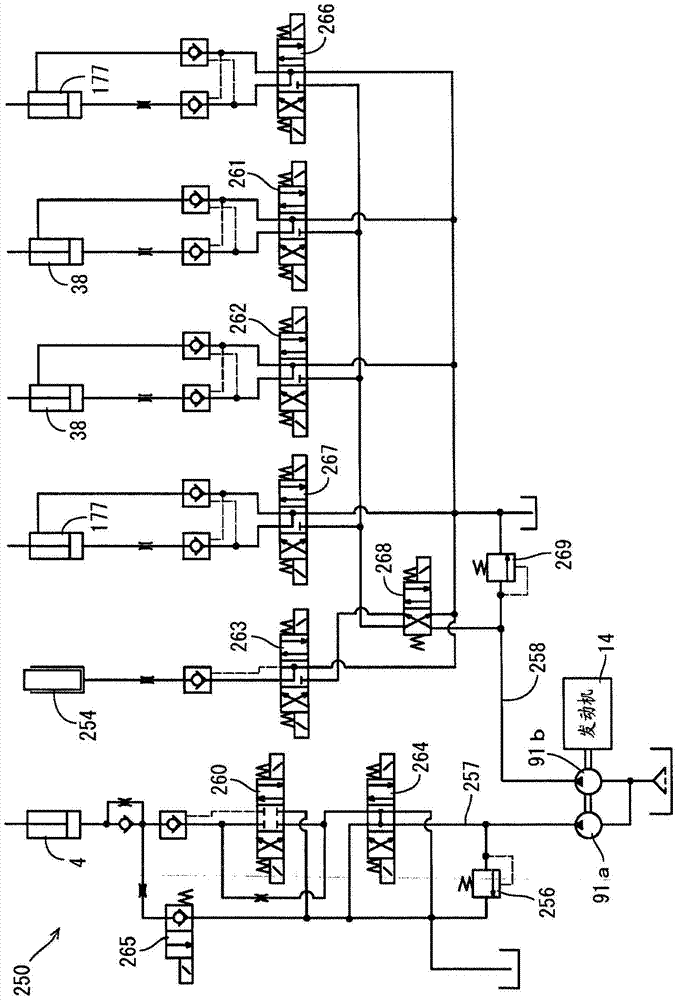

[0069] Such as figure 1 as well as figure 2 As shown in FIG. 2 , a traveling body 1 supported by a pair of left and right traveling crawler belts 2 as a traveling part is provided. The front portion of traveling body 1 is equipped with one side harvesting by single-acting lifting hydraulic cylinder 4 that can be adjusted around harvesting rotation fulcrum shaft 4a, and the harvesting device 3 that 6 ridges of grain stal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com