Coil wiring element and method for manufacturing coil wiring element

A manufacturing method and wiring technology, which can be applied to coils, electrical components, and the size/direction of the magnetic field, which can solve the problems of difficult to form and difficult to form high-density winding coil wiring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, the present invention will be described based on preferred embodiments with reference to the drawings.

[0050]

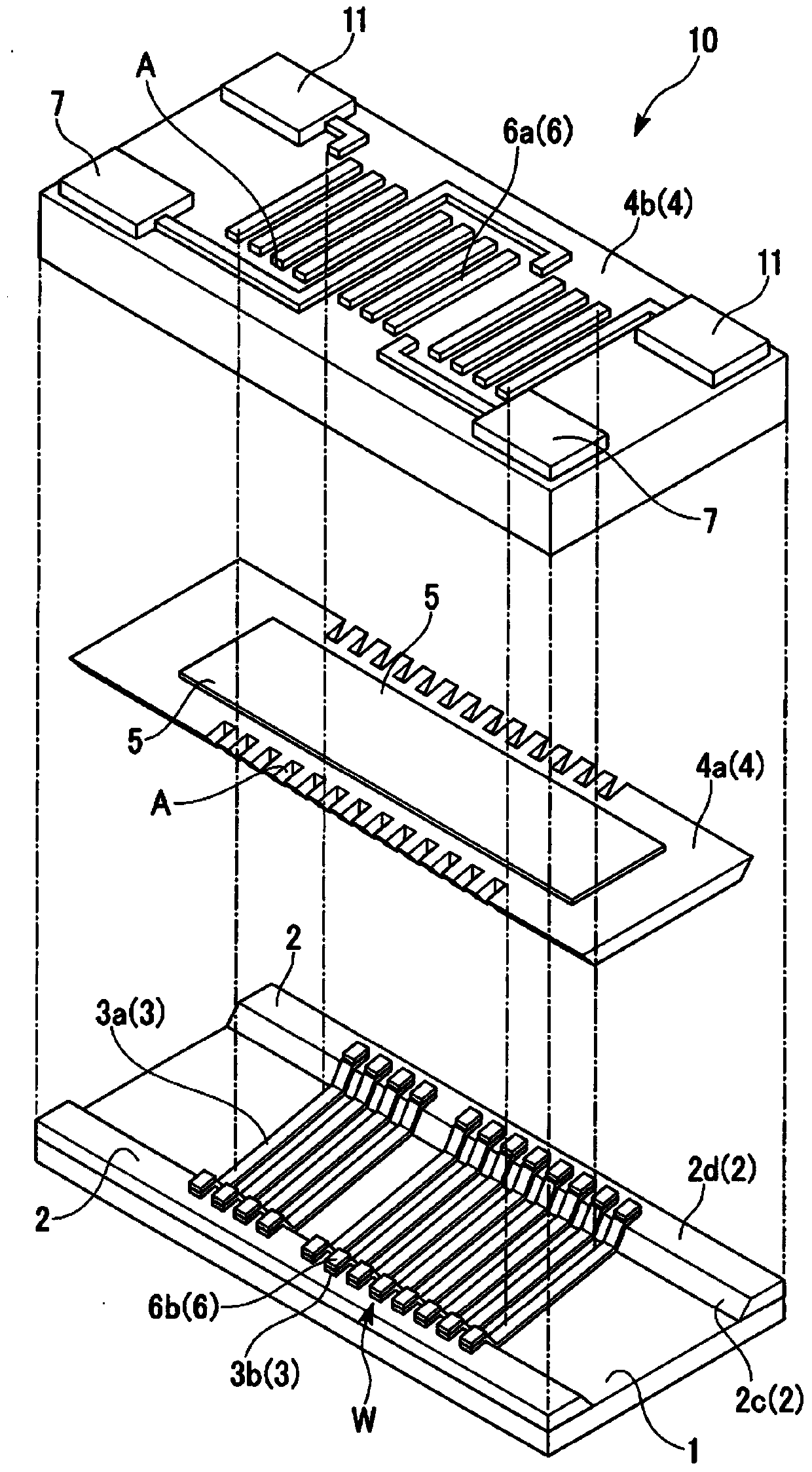

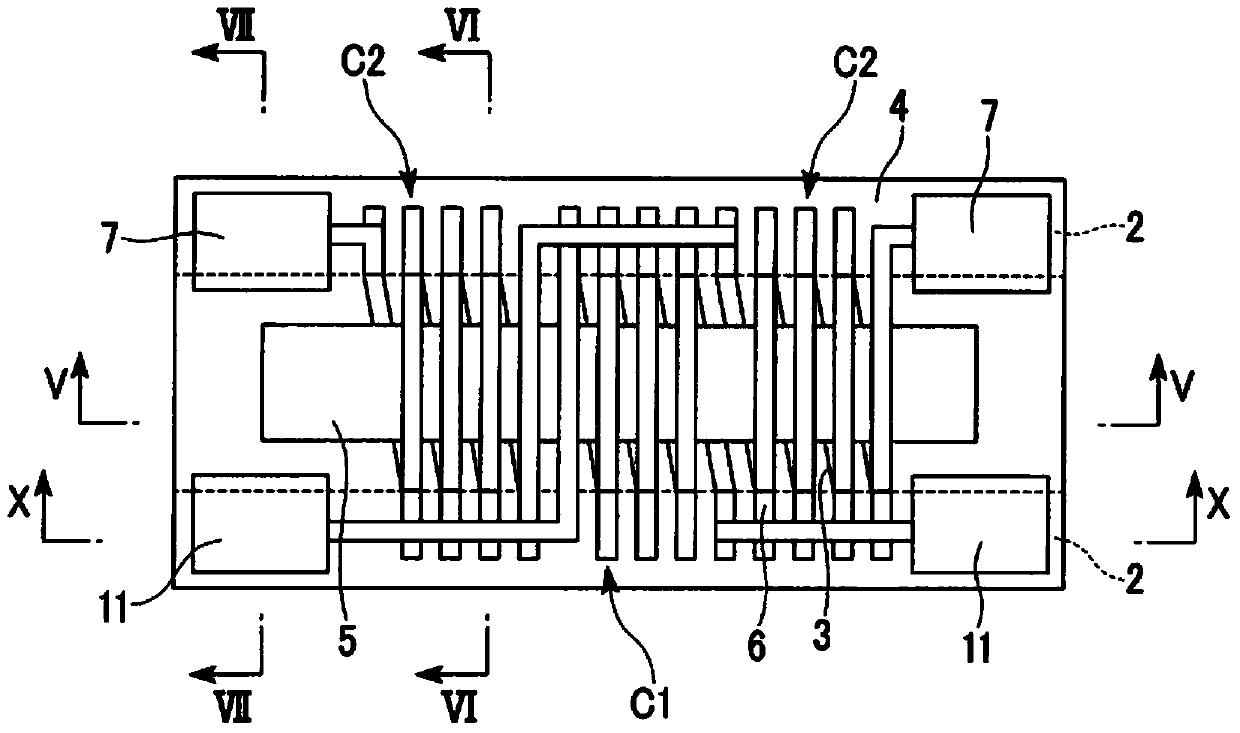

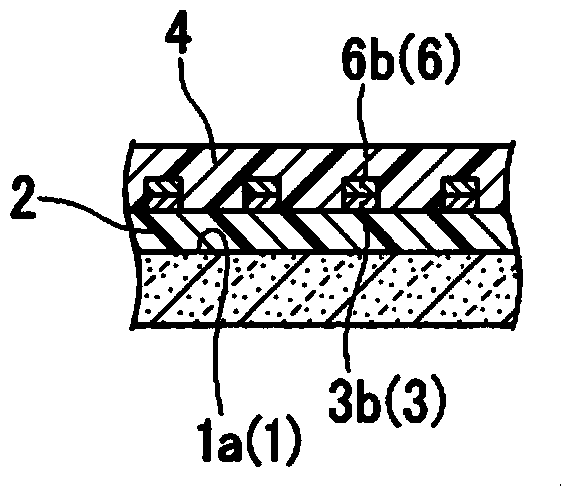

[0051] figure 1 It is an exploded perspective view showing the coil wiring element 10 according to the first embodiment of the present invention. In this exploded perspective view, it is divided into a member group consisting of the substrate 1, the second resin part 2 and the first wiring 3, and a first part 4a (part of the first resin part 4) of the first resin part 4 and a magnetic body ( The component group consisting of the magnetic core) 5 and the component group consisting of the second part 4 b of the first resin part 4 (other parts of the first resin part 4 ) and the second wiring 6 are shown as if separated from each other. figure 2 It is a perspective view in which the first resin part 4 is transparently shown from above.

[0052] The coil wiring element 10 has: a plurality of first wirings 3 (lower side wirings) formed on a sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com