Remote maintaining device for reaction kettle

A technology for overhauling devices and reactors, applied in chemical/physical/physicochemical fixed reactors, chemical/physical processes, pressure vessels used in chemical processes, etc., can solve problems such as prone to personal accidents, shorten maintenance time, etc., and achieve Prevention of personal accidents, improvement of production efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

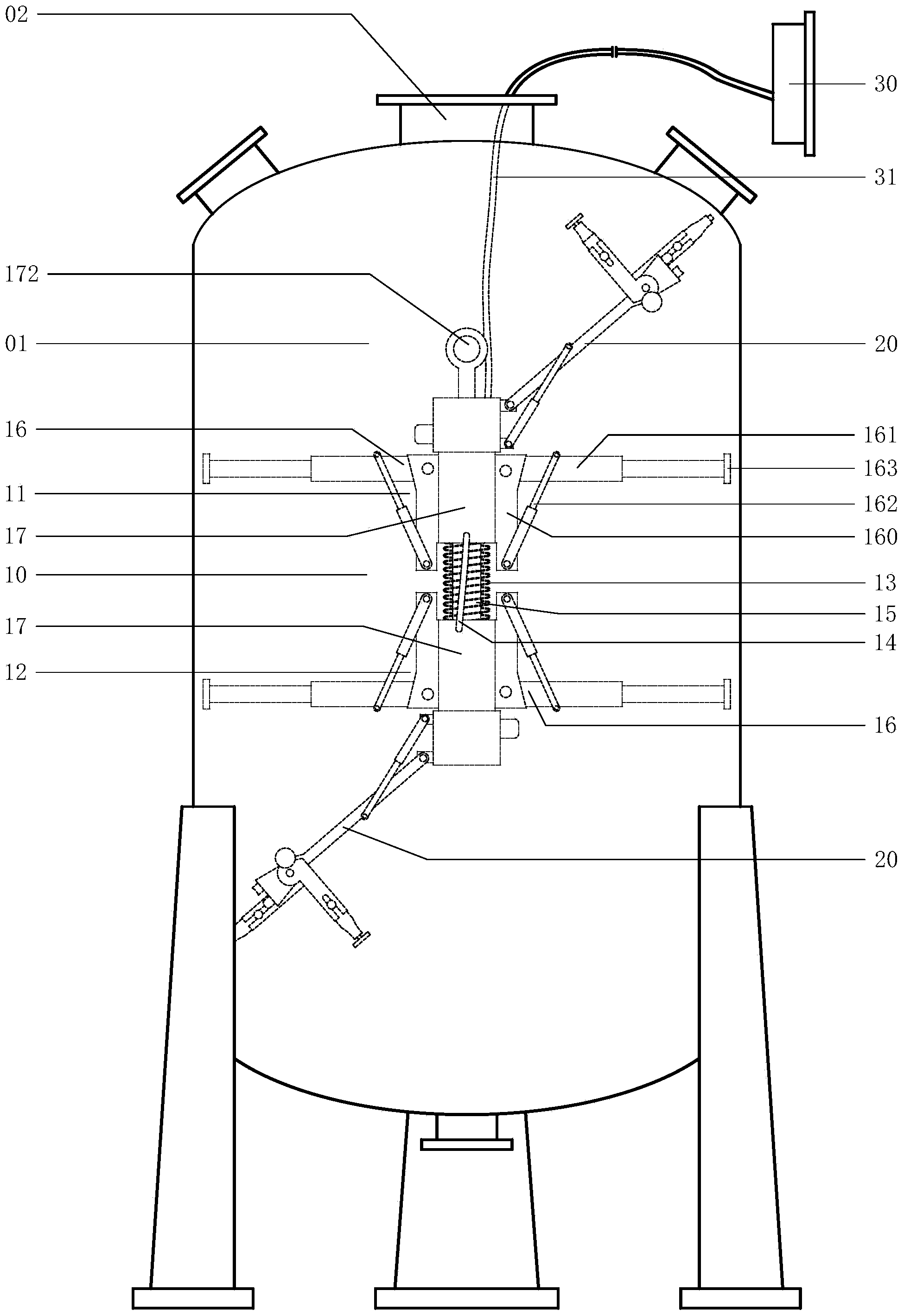

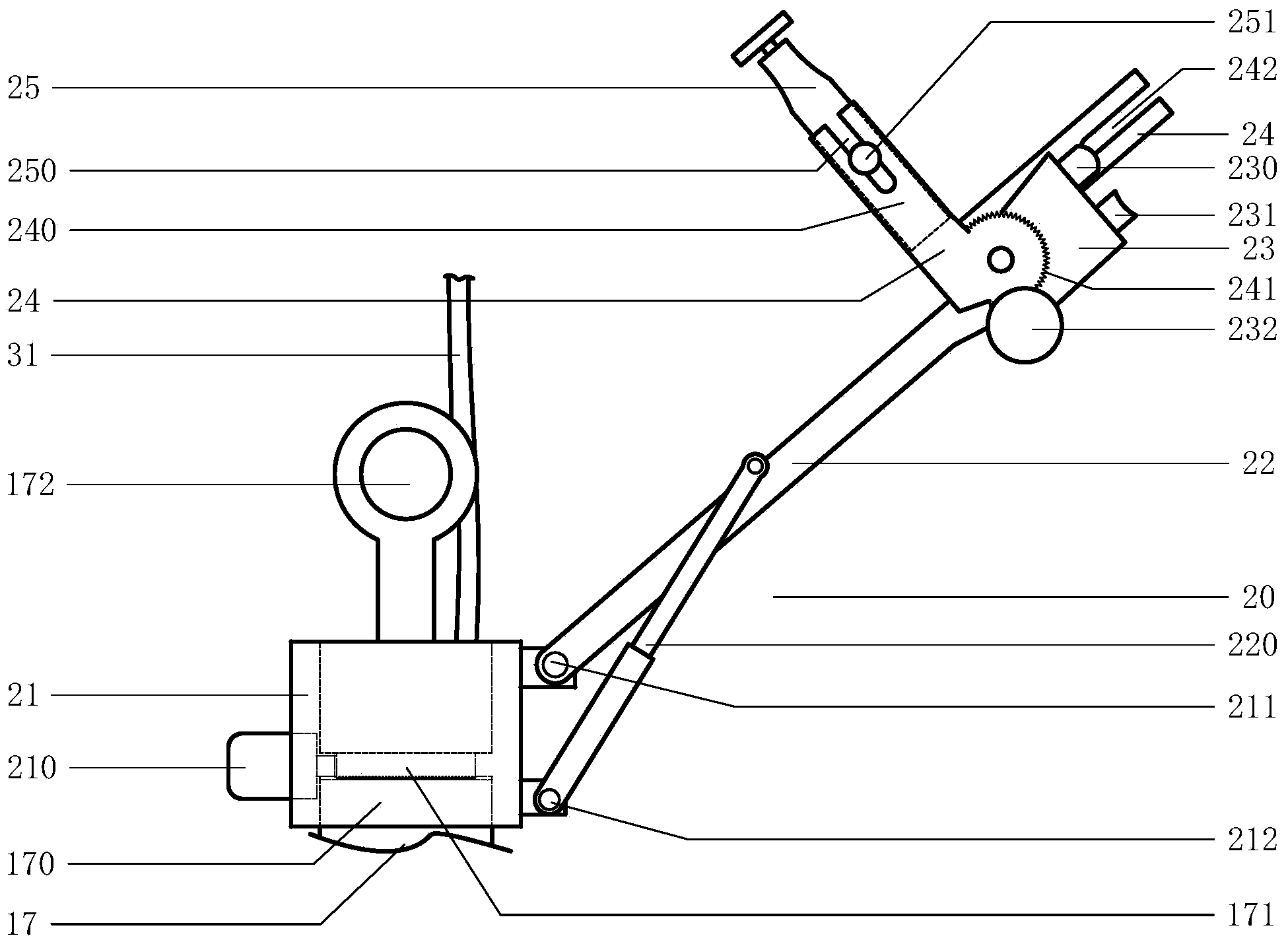

[0018] In factories producing chemical raw materials, various reaction kettles are widely used, and the reaction kettle includes a vertical kettle body 01 and a horizontal kettle body. This embodiment is suitable for use in conjunction with the vertical kettle body 01. The vertical kettle body 01 is installed in the production plant matching the reaction kettle. The power kettle mouth 02 is installed on the top of the vertical kettle body 01, and the feed pipe and explosion-proof pipe are installed on the wall and bottom of the vertical kettle body 01. , temperature control tube, measuring tube and outlet of the discharge kettle, etc., a lifting hook 03 is provided on the production plant at the top of the vertical kettle body 01.

[0019] When the agitator, temperature control device, measuring device, transmission device and other equipment in the vertical kettle body 01 are damaged, the maintenance worker first opens the power kettle port 02, and installs a detachable electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com