Directional steel wire belt type pneumatic tire

A technology of pneumatic tires and steel wire belts, applied to the reinforcement layer of pneumatic tires, tire parts, transportation and packaging, etc., can solve the problems of tire failure, increased shear force and damage of steel wire and rubber, and improve durability And the use of safety and stability, the effect of avoiding tire failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

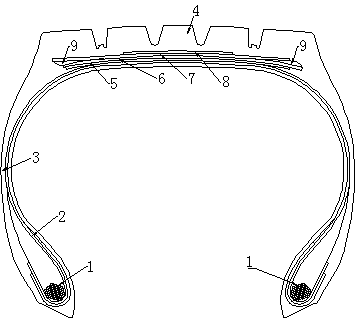

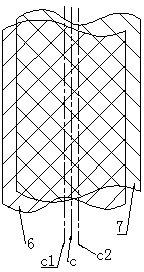

[0015] Example: such as figure 1 , 2 The shown directional steel belt pneumatic tire includes at least one pair of annular bead ring assemblies 1 arranged in parallel at the bead position, at least one layer of ply 2 wrapped around the bead rings, a belt reinforced with steel cords The belt layer assembly, the tread structure 4 with a pattern placed outside the belt layer assembly, and the sidewall 3 extending from the tread to the bead portion. The belt assembly is composed of at least two working belt layers 6, 7, at least one protective layer 8 and at most one transition layer 5. The steel cords of the belt layers 6 and 7 of the two working layers are arranged in opposite directions. The belt layers 6 and 7 of the two working layers are provided with insulating rubber parts 9 at the end points of both sides to reduce the shear stress at the end points of the belt layers during operation. The transverse centerline c1 and transverse centerline c2 of the belt layers 6 and 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com