Rapid installation and automatic adhesive tape cutting device

An automatic and adhesive strip technology, which is applied in the directions of transportation and packaging, sending objects, thin material processing, etc., can solve the problem of unsolved adhesive tape drying, complex structure and other problems, so as to improve the bonding quality and increase production efficiency , to ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

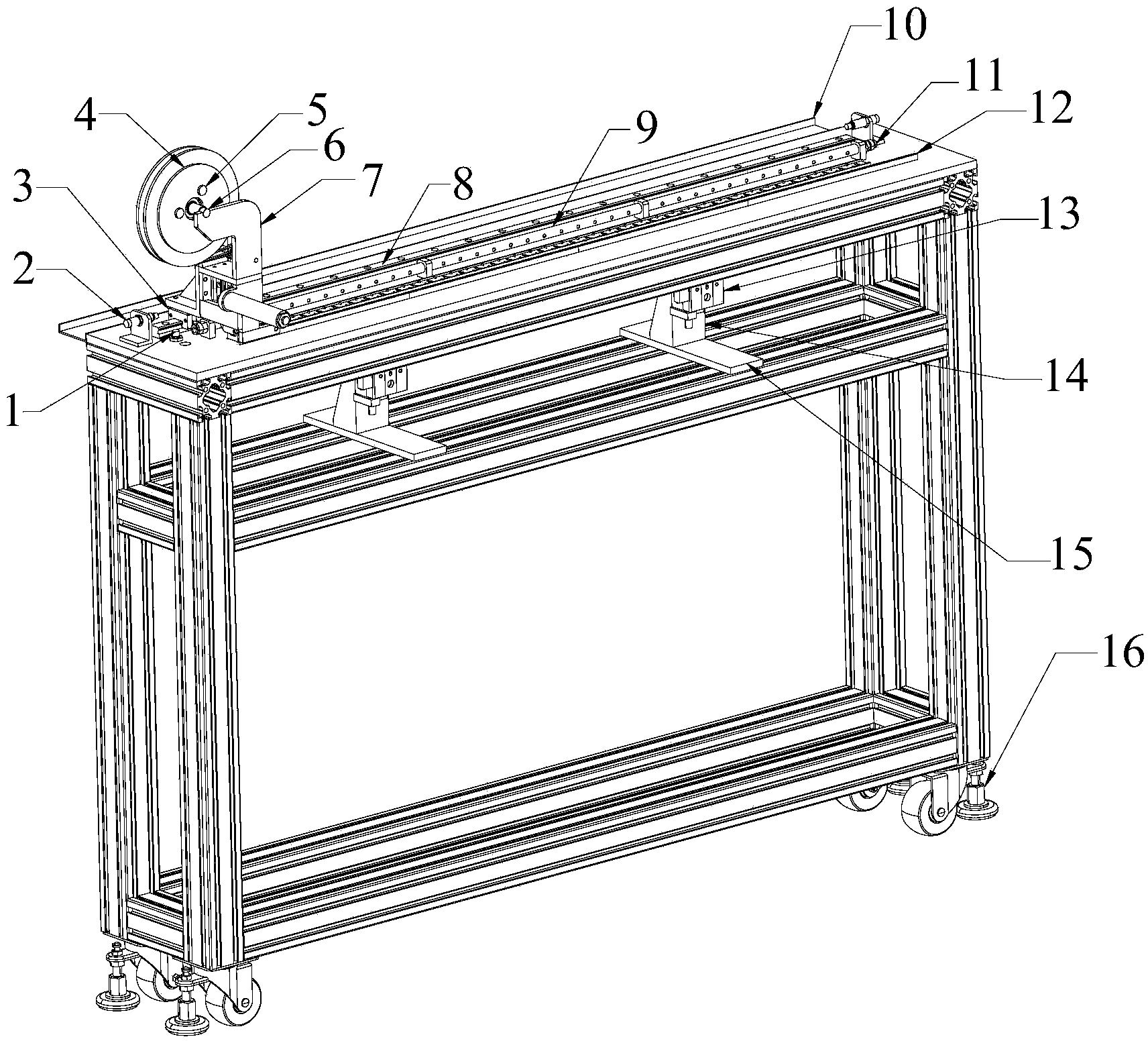

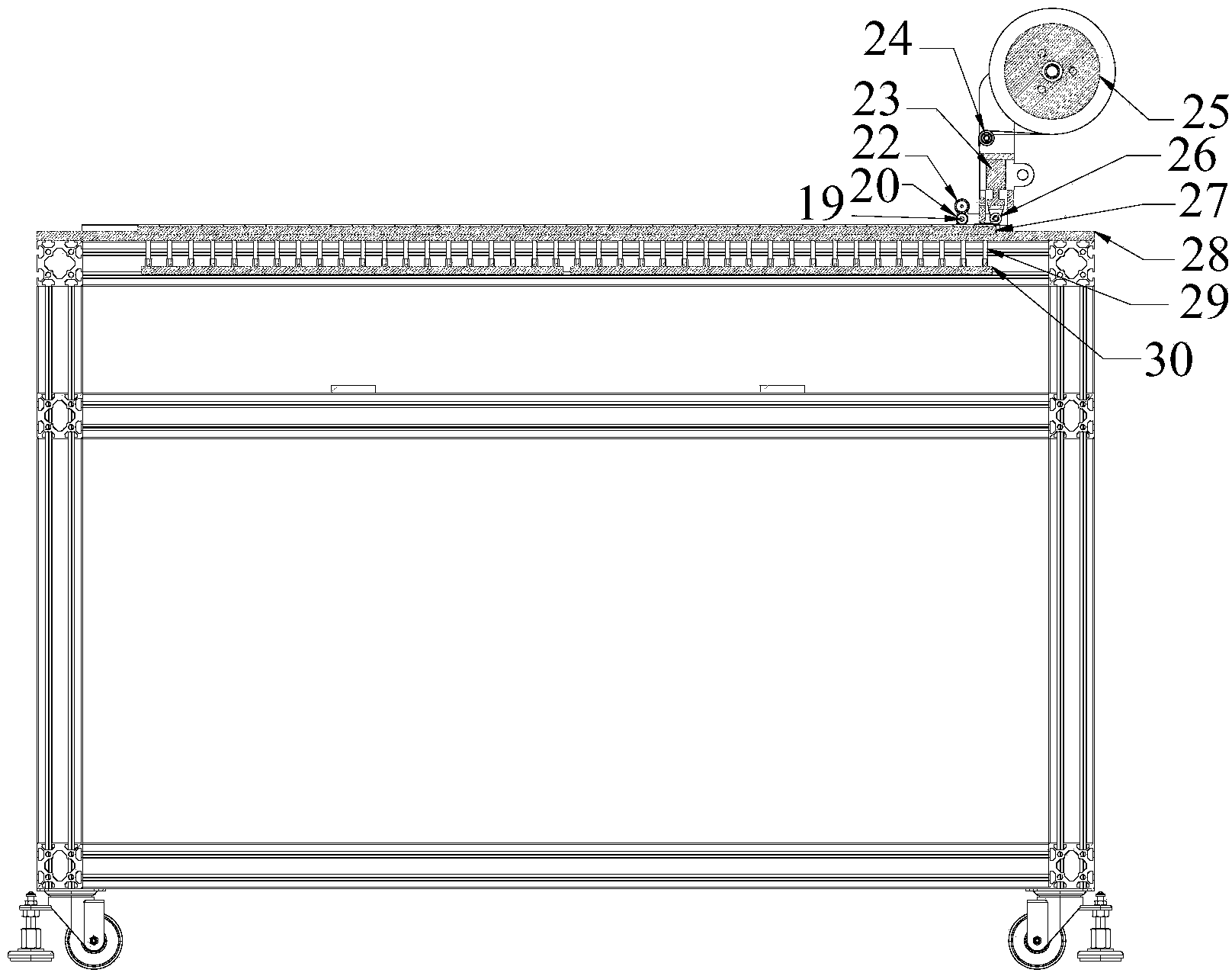

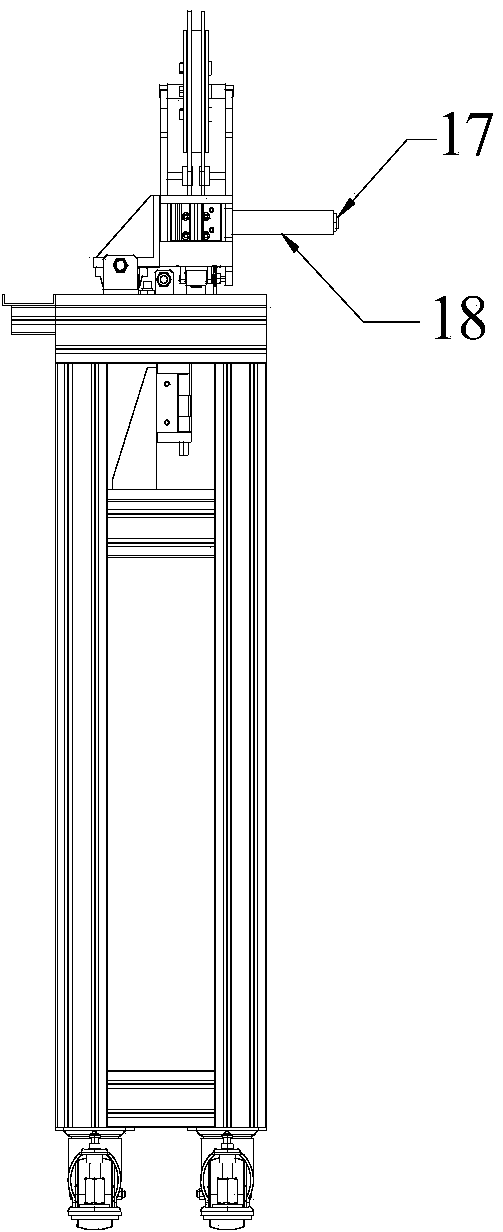

[0029] A quick installation and automatic glue cutting device, its structure is as follows Figure 1-3 As shown, it includes: a support mechanism, a nail column installation mechanism, a drying mechanism, a tape installation mechanism, and a tape cutting mechanism arranged on the support mechanism.

[0030] The support mechanism is a frame with a table top 28 on the top, a crossbeam for installing the cylinder 13 in the middle, and casters 16 connected to the bottom to facilitate the free movement of the support mechanism.

[0031] The stud mounting mechanism includes a stud base 27 for placing studs on the table top 28, a thimble 29 and a thimble plate 30 located below the deck 28, and the driving thimble 30 drives the thimble 29 upward to push the studs out of the stud base 27. Cylinder 13, wherein cylinder 13 is positioned at the below of table top 28, is connected on the crossbeam of support mechanism through cylinder installation plate 14 and support plate 15, convenient ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com