Fast oil drum opener

A bottle opener and oil drum technology, applied in the petroleum field, can solve problems such as low efficiency and troublesome opening of the opener, and achieve the effects of fast opening, stable opening, and high opening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

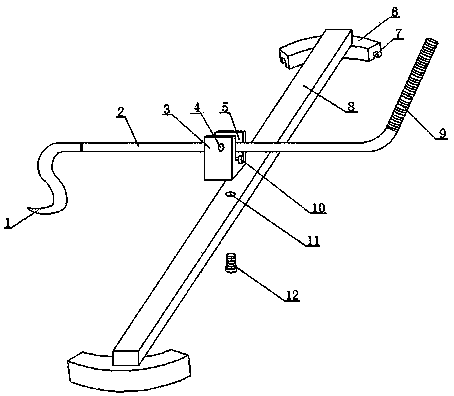

[0016] See figure 1 , Quick loading oil barrel bottle opener, including hook 1, support rod 2, support rod rotating seat 3, rotating pin 4, fixing frame 8, handshake handle 9 and screw 12, the support rod rotating seat 3 is provided with a support The rod clamping groove 5, the supporting rod 2 is installed in the supporting rod clamping groove 5 through the rotating pin 4, forming a rotating structure of the supporting rod 2 with the rotating pin 4 as the rotating shaft, and a through hole 11 is provided in the middle of the fixing frame 8. The screw 12 passes through the through hole 11 and is threadedly connected with the bottom of the support rod rotating seat 3 to form a rotating structure of the support rod rotating seat 3 with the screw 12 as the rotating shaft. The left end of the support rod 2 is threadedly connected to the hook 1 and the right end of the support rod 2 Bend upwards and screw the handle 9 to it.

[0017] In this embodiment, when the lid is opened, the fix...

Embodiment 2

[0019] This embodiment is optimized on the basis of Embodiment 1 or Embodiment 2 as follows: the supporting rod rotating seat 3 is located at the right open end of the supporting rod 2 and a limit block 10 is also provided.

[0020] In this embodiment, in order to prevent the lid opener from using too much force and damage the lid and the lid opener, a limit block 10 is provided so that the staff can only press down the lever 2 to a certain angle when opening the lid. The lid is deformed due to excessive force to protect the lid. At the same time, it can also protect the support rod 2 and the rotating pin 4, and prevent the barrel from overturning, which can avoid unnecessary losses and accidents.

Embodiment 3

[0022] This embodiment is optimized on the basis of Embodiment 1 as follows: the lower sides of both ends of the fixing frame 8 are connected to an arc-shaped fixing plate 6, and the lower end of the fixing plate 6 is provided with an arc-shaped slot 7.

[0023] The fixing plate 6 in this embodiment is used to support the fixing frame 8 to prevent the fixing frame 8 from contacting with the lid of the barrel so that the fixing frame 8 is pressed down when the lid is opened, causing the lid to deform, and the slot 7 can be fitted with the edge of the barrel to fix The frame is integrally fixed to prevent the fixing frame 8 from sliding when the cover is opened to affect the opening of the cover, thereby improving the stability of the entire structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com