Combined water treatment impeller

A water treatment, combined technology, applied in the direction of water/sludge/sewage treatment, sustainable biological treatment, water aeration, etc. Problems such as inability to form at one time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

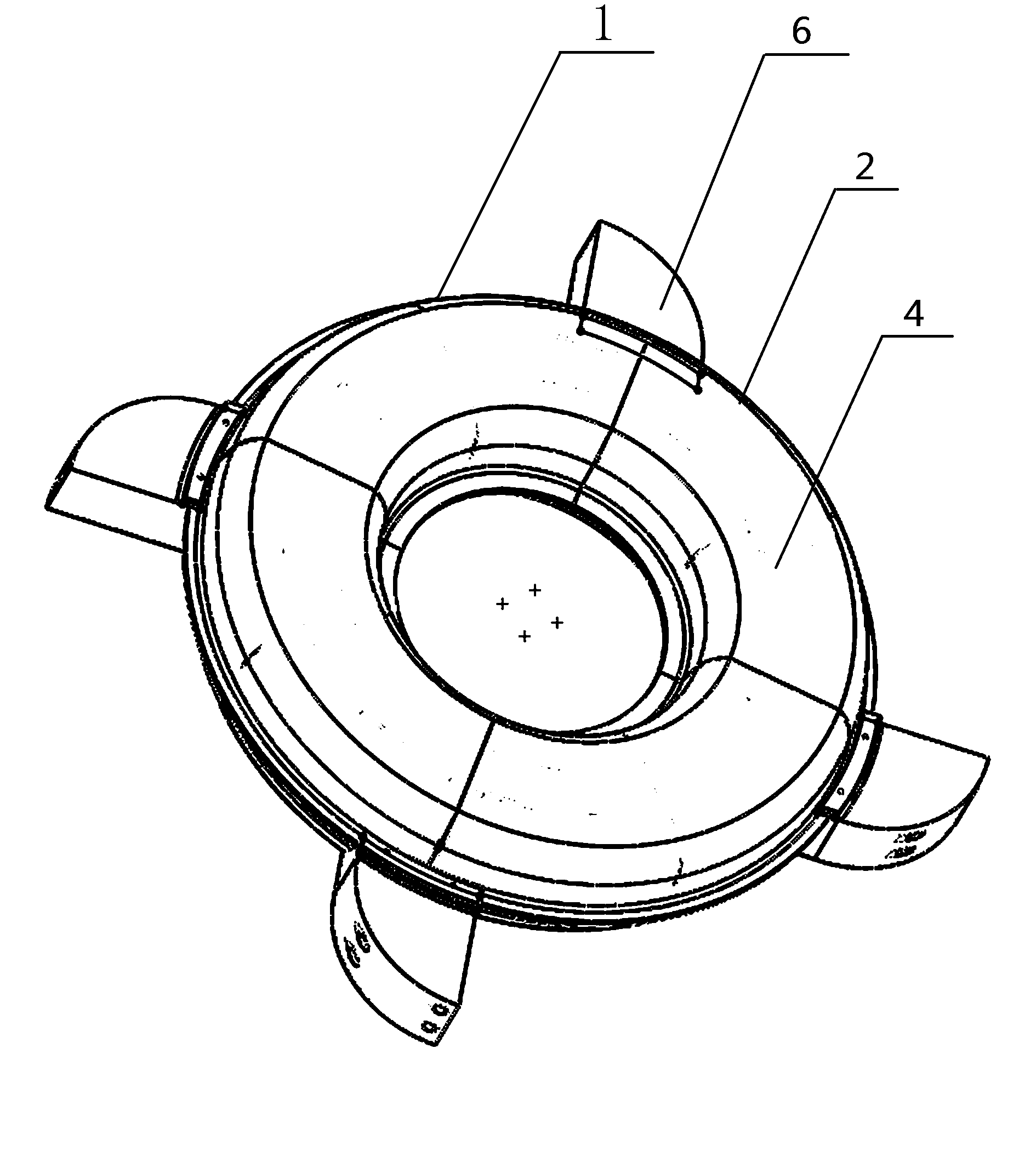

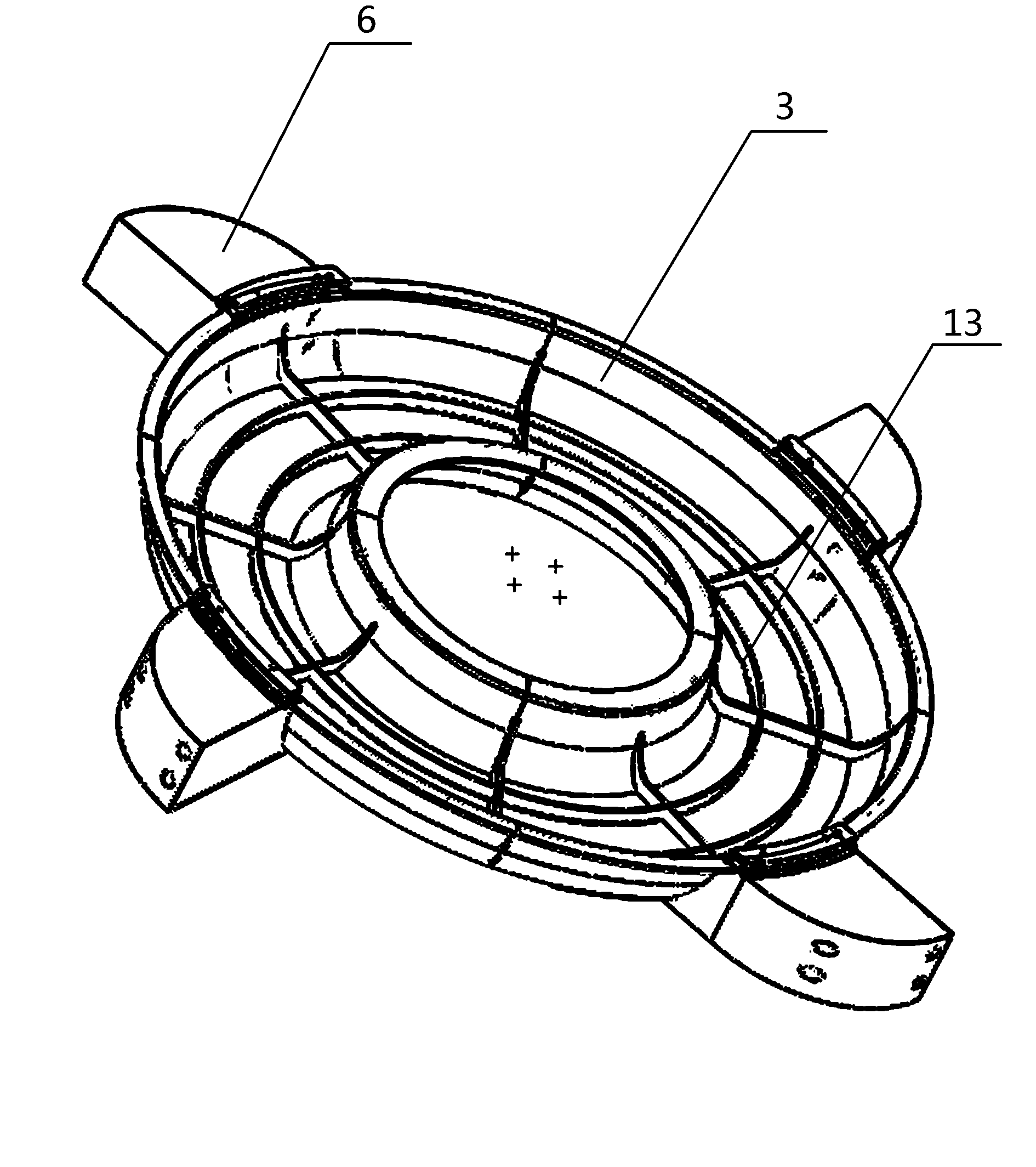

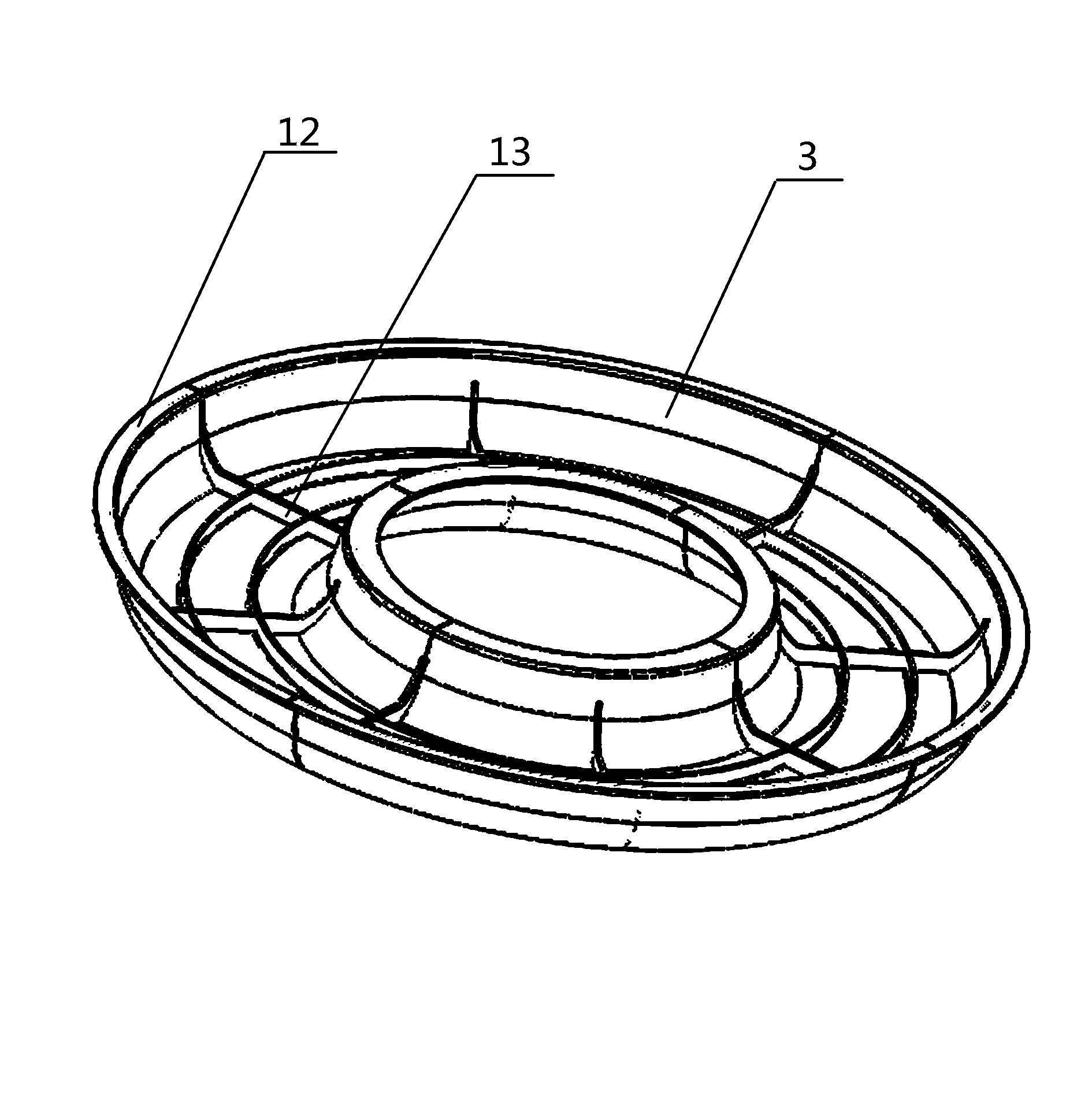

[0013] The invention discloses a combined water treatment impeller, which mainly includes an impeller body 1, which is different from the prior art in that: the impeller body 1 is in the shape of an annular body, and the inner cavity of the annular body is hollow, and the annular body is composed of The upper ring body 2 and the lower ring body 3 are spliced up and down, and at least four blade bodies 6 are equidistantly distributed on the edge of the impeller body 1 . The inner cavity of the blade body 6 is hollow, which can effectively reduce the weight of the impeller body.

[0014] In a specific implementation, the upper ring body 2 is formed by splicing four upper circular arc pieces 4 to form a ring body, and the upper circular arc pieces 4 form a quarter circular arc body. The lower ring body 3 is formed by splicing four lower circular arc piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com