Self-generating foam jelly profile control agent prepared with oilfield reinjection water and its preparation method and application

A technology of oilfield water reinjection and oilfield water injection, which is applied in the field of self-generating foam jelly preparation, can solve the problems of high water temperature and high salt content of reinjection water, and achieve the effects of reducing liquid drainage speed, good foam stability and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

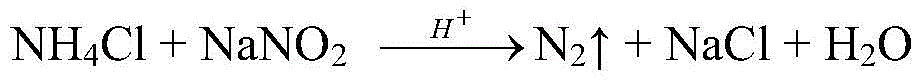

Method used

Image

Examples

Embodiment 1

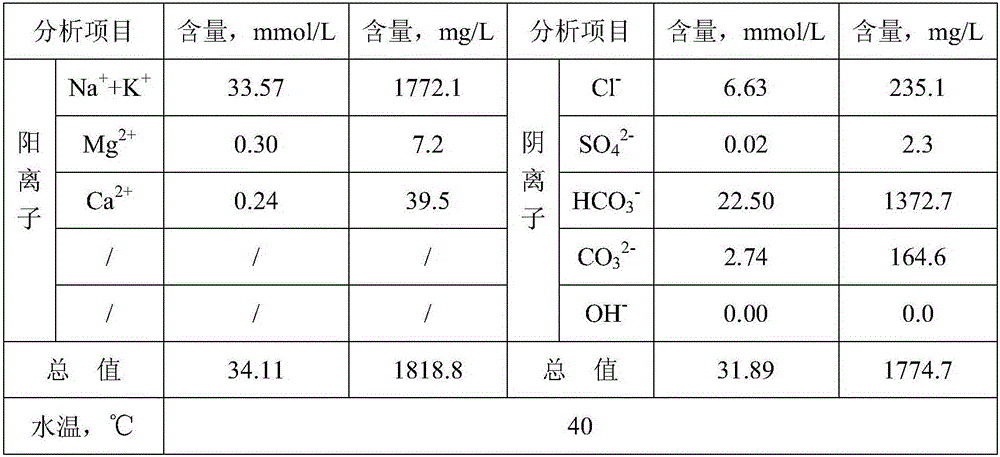

[0047] Polyacrylamide (degree of hydrolysis 27.8%, molecular weight 15 million) 0.2%, chromium malonate crosslinking agent 0.2%, NH 4 Cl2.0%, NaNO 2 1.6%, 0.15% propionic acid (catalyst), 0.3% OP-10 foaming agent, 3% sodium gluconate stabilizer, and the rest is oilfield reinjection water (40°C).

[0048] Preparation:

[0049] Dissolve the polyacrylamide with oilfield reinjection water for 4 hours, after the dissolution is complete, then add other components, stir and dissolve evenly.

[0050]Glue test results:

[0051] The prepared profile control agent solution, under the condition of water temperature of 40°C, will not form gel after being placed for 72 hours, which provides a guarantee for the safety of construction. At 50°C, the gelation time is 6 hours, the breakthrough pressure is 1.69MPa, and the plugging rate is 99.7%.

Embodiment 2

[0053] As described in Example 1, the difference is that the amount of propionic acid is 0.10%.

[0054] The prepared profile control agent solution, under the condition of water temperature of 40°C, is placed for 72 hours without gelling. At 50°C, the gelation time was 10 hours, the breakthrough pressure was 2.91MPa, and the plugging rate was 99.8%.

Embodiment 3

[0056] As described in Example 1, the difference is that the amount of propionic acid is 0.05%.

[0057] The prepared profile control agent solution will not form a gel when placed at a water temperature of 40°C for 72 hours; at 50°C, the gelation time is 24 hours, the breakthrough pressure is 4.53MPa, and the plugging rate is 99.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com