Withdrawing mechanism used during threading of sewing equipment

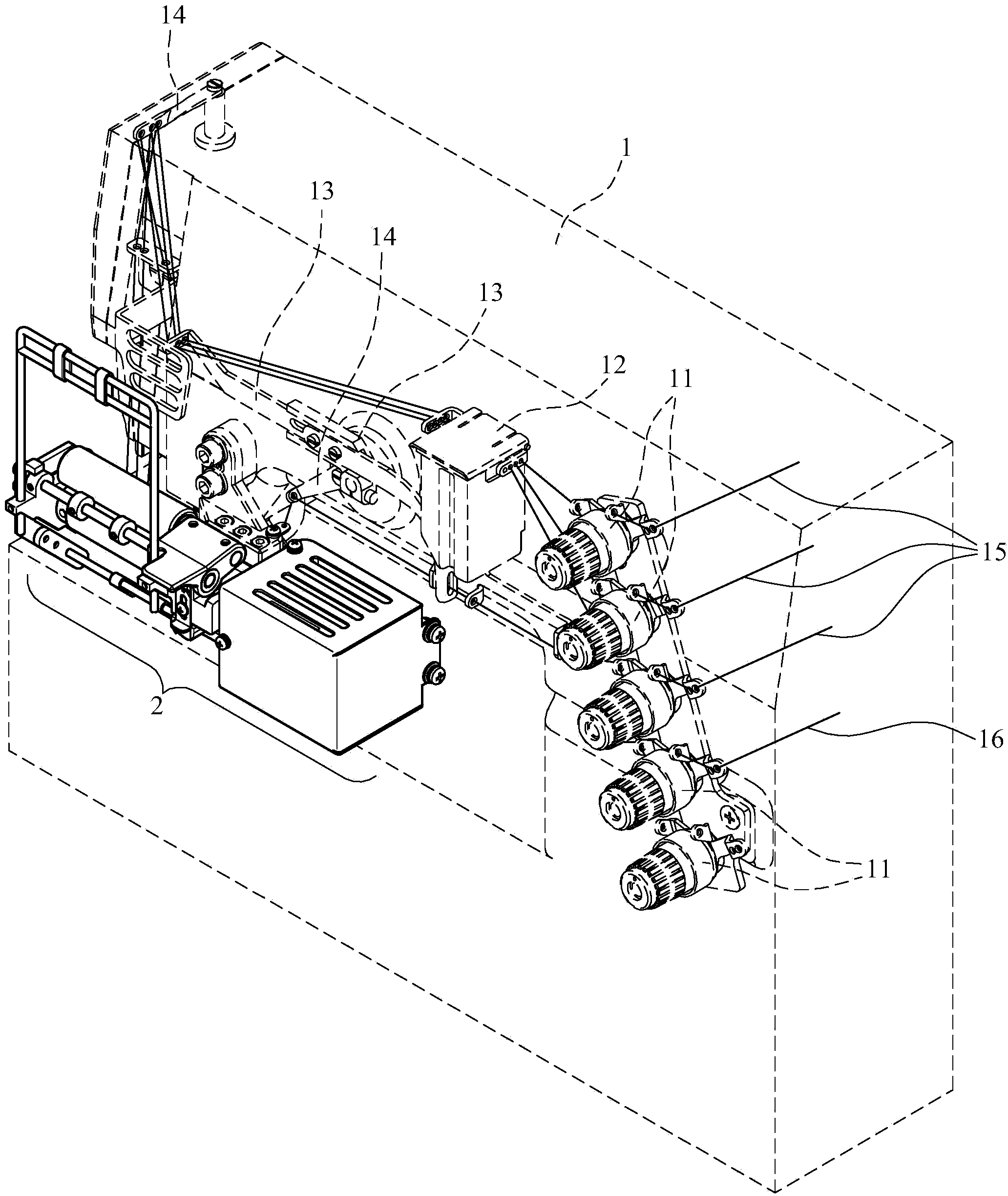

A sewing machine and threading technology, which is applied to sewing machine components, sewing machine protection devices, cloth feeding mechanisms, etc., can solve the difficulties of threading 15 and bottom stitching 16, block the threading operation, and fully meet the requirements of the garment manufacturing industry. Diverse needs and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

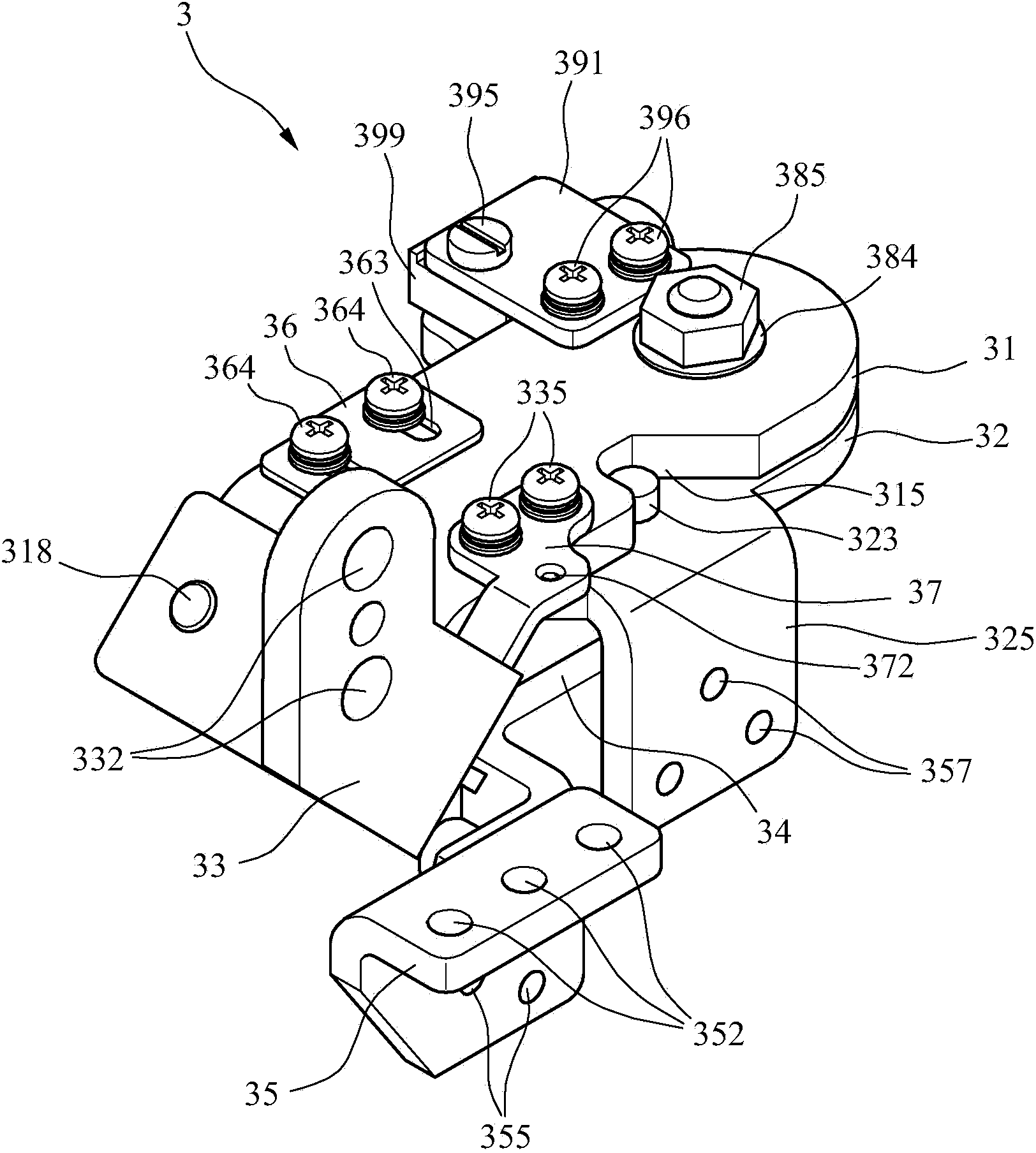

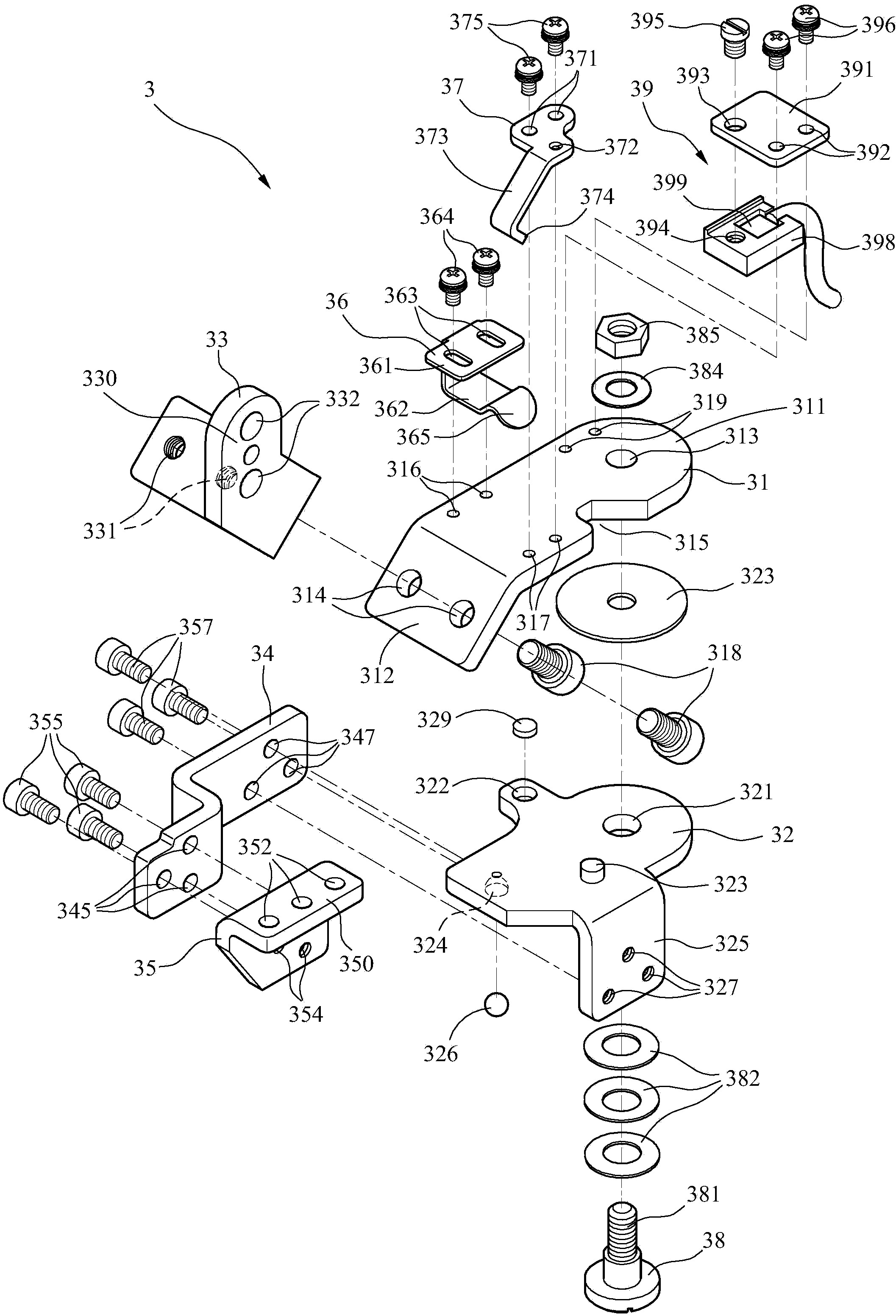

[0044] see Figure 2 to Figure 4 , Figure 6 Shown in, it is a preferred embodiment of the removal mechanism when the sewing equipment of the present invention is threaded. The quick removal mechanism 3 in this embodiment includes a base bracket 31, a steering bracket 32, a Bracket fixing part 33 , a zigzag connecting part 34 , a fixing part 35 , a spring clip 36 , a threading washer 37 , a pivot 38 and a safety switch 39 .

[0045] One end of the base bracket 31 is an arc-shaped end plate portion 311 , and the other end is a downwardly inclined inclined portion 312 . The end plate portion 311 is provided with a first shaft hole 313 for the pivot shaft 38 to pass through, and the inclined portion 312 is provided with a perforation 314 for locking the bracket fixing member 33 on the sewing machine 1 (such as Figure 10 shown in ).

[0046] One side of the base bracket 31 is provided with an oblique notch 315 and two screw holes 317 to lock the positioning column 323 of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com