Vertical and horizontal pipe pile loading device

A technology of horizontal loading and vertical loading, which is applied in the field of loading devices for pipe piles, can solve the problems that vertical and horizontal loading devices cannot be integrated, and achieve the effect of avoiding displacement changes and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

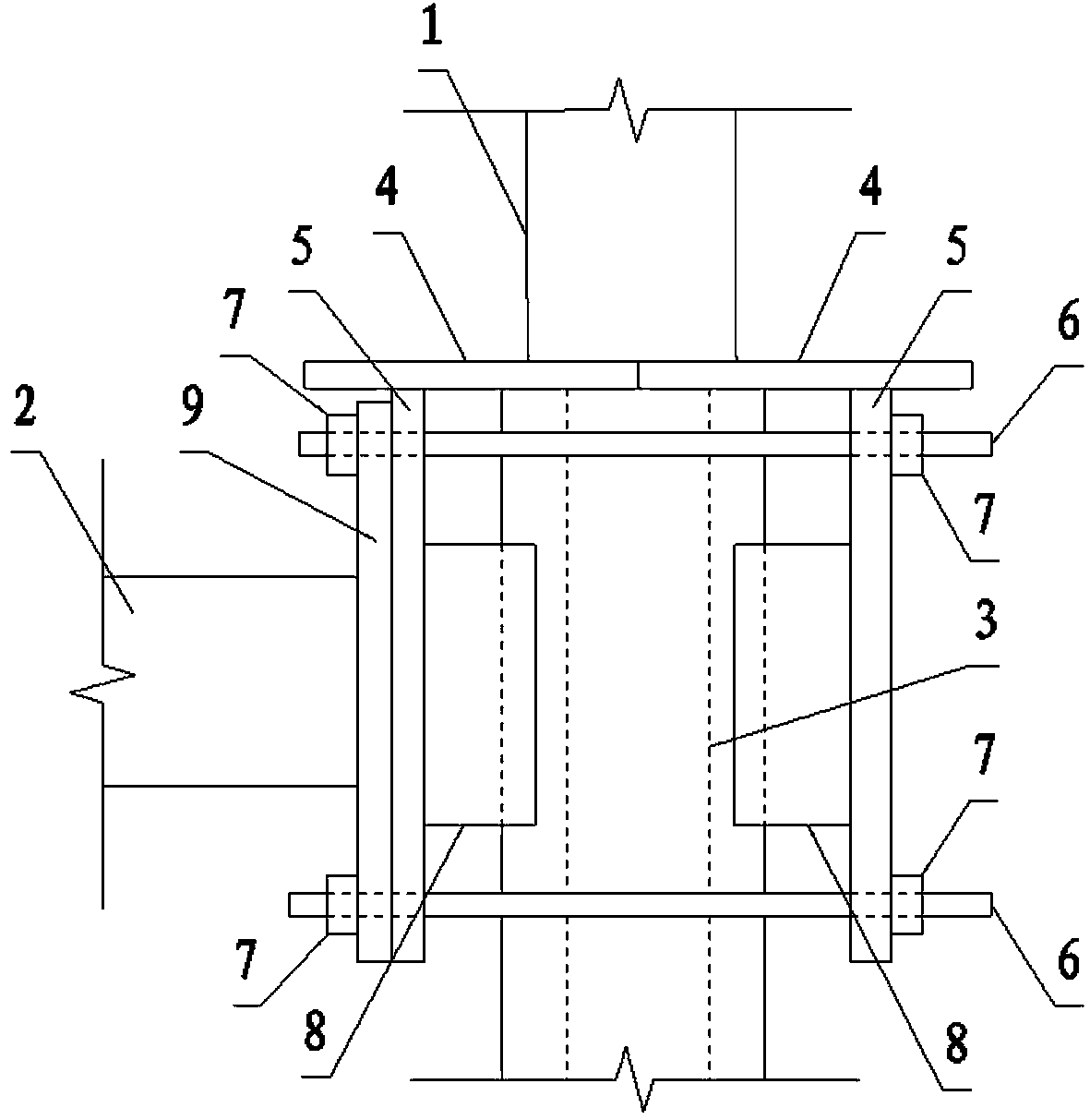

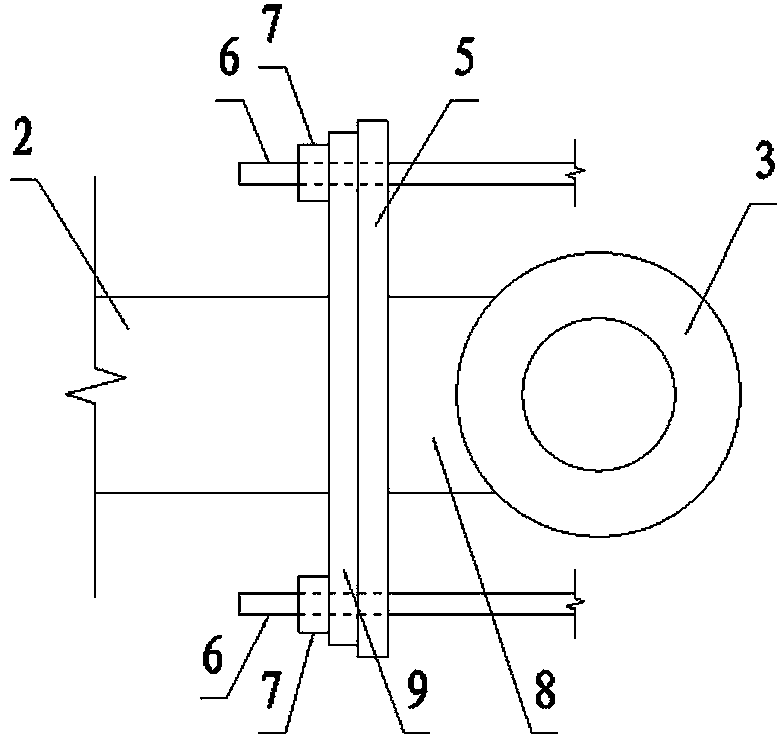

[0010] Vertical and horizontal loading devices for pipe piles, including vertical loading jack 1 and horizontal loading jack 2, and two vertical loading plates 4 placed on the top of pipe pile 3, two groove blocks 8, and four screw rods 6 Each vertical loading plate 4 protruding out of the pipe pile 3 is vertically provided with a horizontal loading plate 5, and the two horizontal loading plates 5 are parallel to each other. One side of the groove block 8 is a plane, and the opposite side For the arc surface matched with the outer wall of the pipe pile 3, the two groove blocks 8 are fixed on the inside of the two horizontal loading plates 5 through the plane, and the vertical loading jack 1 is fixed above the top of the pipe pile 3 and its plunger is connected with the two The butt joint of the vertical loading plate 4 is loaded and matched, and the end of the horizontal loading jack 2 is fixed with a backing plate 9, and the backing plate 9 is attached to the outside of the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com