Replacing and gap-repairing device and method for converter bottom-blowing brick

A converter bottom blowing and gap technology, which is applied in the manufacture of converters, etc., can solve problems such as lack of safe and feasible mechanized operation methods for gap repair, and refractory mud cannot be filled evenly, so as to avoid voids, increase fluidity, and uniform materials smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

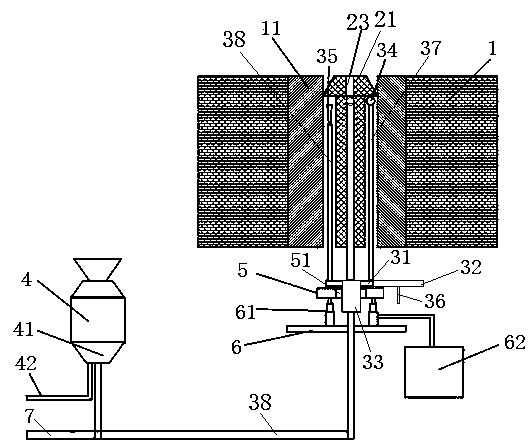

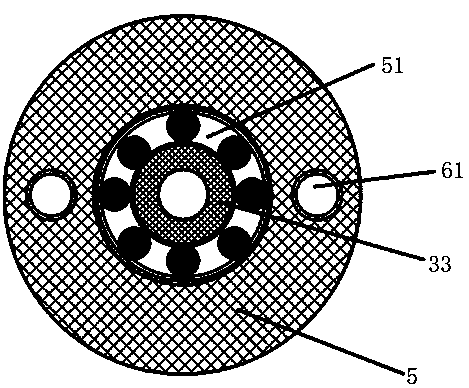

[0044] A method for replacing and repairing gaps in converter bottom blowing bricks, comprising the following steps: (This method uses the aforementioned device for converter bottom blowing brick replacement and gap repairing for testing.)

[0045] step:

[0046] A. Drilling:

[0047] Prefabricate the bottom blown brick 2 according to the diameter of the drilled hole. The diameter of the drilled hole determined by the 80-ton converter blocked bottom blown brick in this embodiment is 130 mm, so the bottom diameter of the round table part 21 of the prefabricated bottom blown brick 2 is 130 mm, and the round table part 21 The height is 50mm; the diameter of the cylindrical part 22 is 110mm; the hole is drilled on the seat brick 11 to be repaired, and the diameter of the hole is equal to the bottom diameter of the circular platform part 21 of the bottom blowing brick 2.

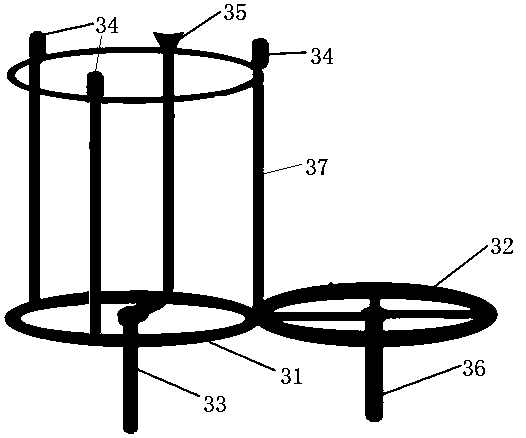

[0048] B. Install bottom blowing brick and gap repair device:

[0049] Smear refractory mud on the side of t...

Embodiment 2

[0055] A. Drilling:

[0056] Prefabricate the bottom blown brick 2 according to the diameter of the drilled hole. The drilled diameter of the bottom blown brick with 120 tons of converter plugging in this embodiment is determined to be 180mm, so the bottom diameter of the round platform part 21 of the prefabricated bottom blown brick 2 is 180mm, and the round platform part 21 The height is 80mm; the diameter of the cylindrical part 22 is 150mm; the hole is drilled on the seat brick 11 to be repaired, and the diameter of the hole is equal to the bottom diameter of the circular platform part 21 of the bottom blowing brick 2.

[0057] B. Install bottom blowing bricks:

[0058] The front end of the circular bezel 21 is coated with refractory mud, and the bottom blowing brick 2 is pushed into the predetermined position by the jacking equipment. The front end of the circular bezel 21 is flush with the top of the drilled hole, and the bottom diameter side of the circular bezel 21 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com