Ring permanent magnet assembly mechanism

An assembly mechanism and permanent magnet technology, applied in mechanical equipment, fixtures, etc., can solve problems such as damage to experimental materials, increased axial repulsion, operator injury, etc., to save time, simple and reliable structure, and increase the force arm. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

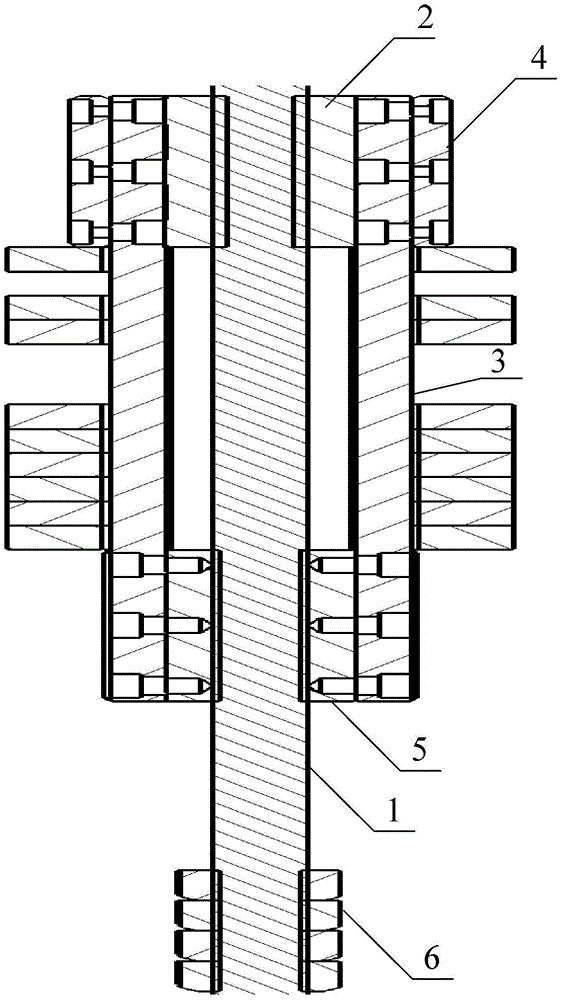

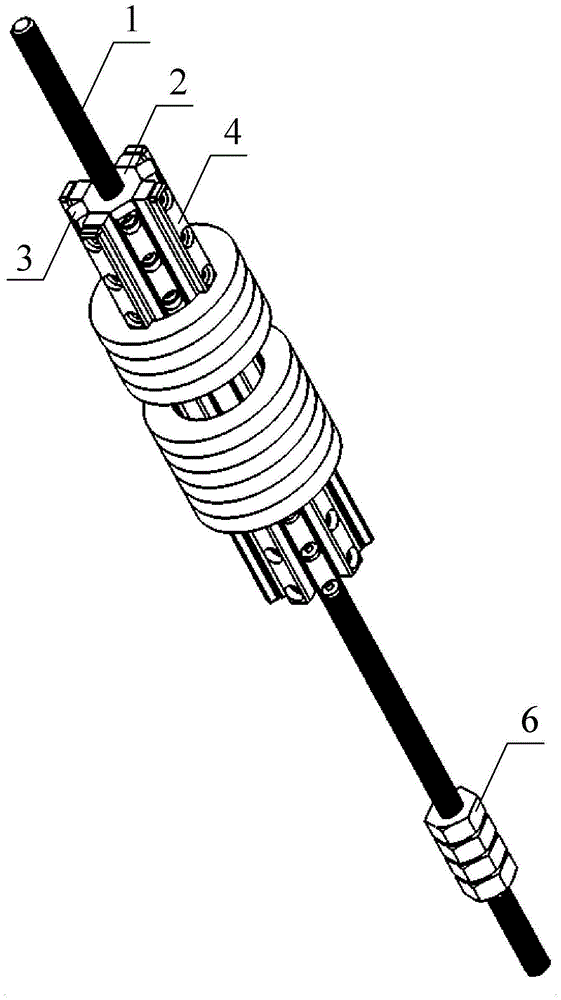

[0019] Specific implementation mode one: combine Figure 1 to Figure 8 To illustrate this embodiment, the annular permanent magnet assembly mechanism described in this embodiment includes a central long stud 1, a threaded sleeve combination, a through-hole sleeve combination and two sets of lock nuts 6;

[0020] The threaded sleeve combination includes a regular octagonal threaded sleeve 2, four equal-length ribs 3 and four metal buttons 4. The external thread of the stud 1 is engaged and connected, the rib 3 is a lath-shaped structure, the length of the rib 3 is twice the length of the regular octagonal threaded sleeve 2, and the width of the rib 3 is equal to the regular octagonal threaded sleeve 2. The side lengths of the sides are equal, and one end of the four ribs 3 is respectively fixed on four non-adjacent side walls of the regular octagonal threaded sleeve 2 by bolts, and the length direction of the four ribs 3 is in line with the regular octagonal thread The directi...

specific Embodiment approach 2

[0031] Specific implementation mode two: combination figure 1 , figure 2 and Figure 8 This embodiment is described. This embodiment is a further limitation of the annular permanent magnet assembly mechanism described in Embodiment 1. In this embodiment, each set of lock nuts 6 is composed of four nuts of the same size.

specific Embodiment approach 3

[0032] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment. This embodiment is a further limitation of the annular permanent magnet assembly mechanism described in Embodiment 1. In this embodiment, the central long stud 1, the combination of threaded sleeves and the combination of through-hole sleeves are all Made of stainless steel material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com