High-dispersion nickel internal electrode slurry for multilayer chip ceramic capacitor and preparation method thereof

A multi-layer chip ceramic and capacitor technology, applied in the direction of fixed capacitor electrodes, multilayer capacitors, fixed capacitor dielectrics, etc., can solve the problems of holes in the inner electrodes, affecting the electrical properties of MLCC finished products, discontinuity and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

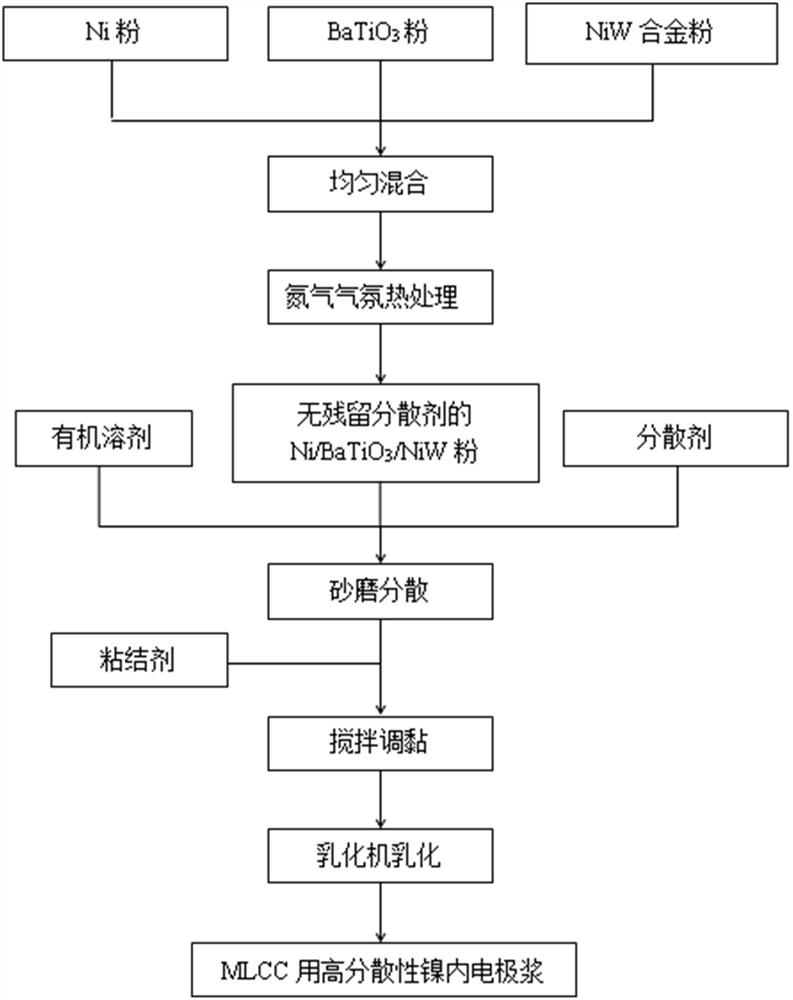

[0046] Based on the above findings, the present invention provides a method for preparing a nickel internal electrode slurry for MLCC, comprising the following steps:

[0047] (1) Ni powder without residual dispersant, BaTiO without residual dispersant 3 Powder, organic solvent, dispersant and NiW alloy powder preferably added without residual dispersant are mixed evenly to obtain slurry A;

[0048] (2) Use a sand mill to sand slurry A to obtain slurry B;

[0049] (3) Add binder to slurry B, mix evenly to obtain slurry C;

[0050](4) Use an emulsifier to emulsify the slurry C to obtain a nickel internal electrode slurry for MCC.

[0051] In the present invention, for preparing the Ni powder of slurry A, BaTiO 3 Powder and NiW alloy powder do not contain residual dispersant. In the production of Ni powder, BaTiO 3 Dispersants are usually used in the process of Ni powder and NiW alloy powder, resulting in Ni powder, BaTiO 3 Powder and NiW alloy powder products contain a ce...

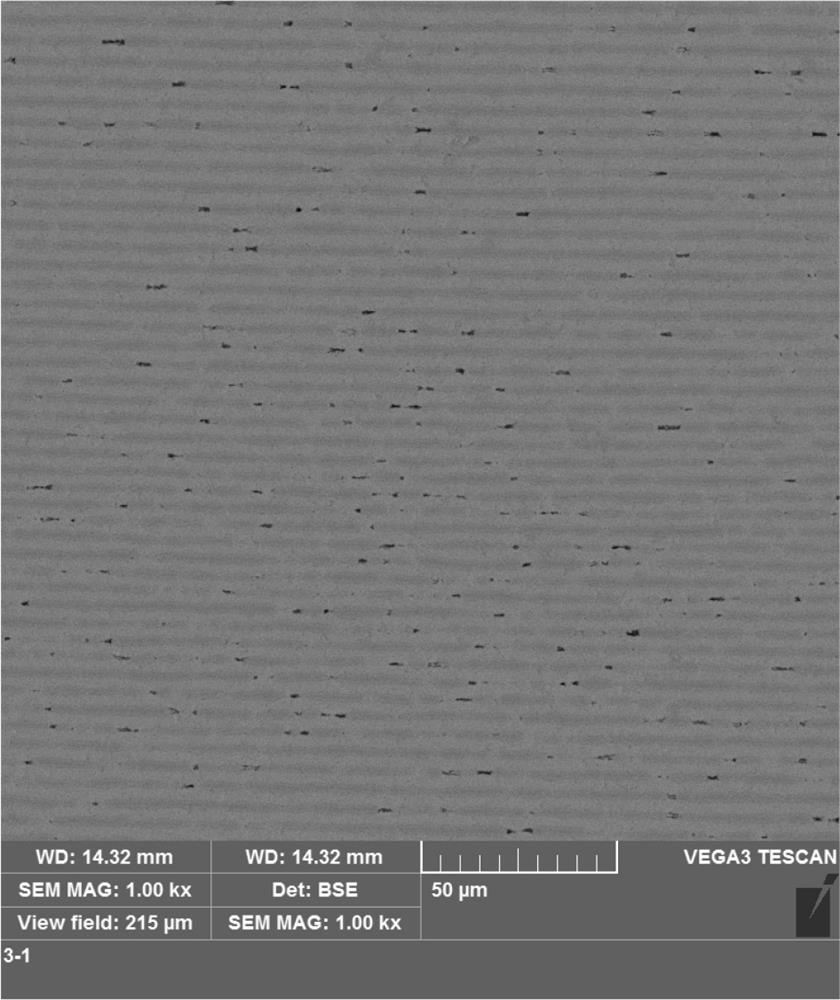

Embodiment 1

[0085] This embodiment prepares a highly dispersible nickel internal electrode slurry for MLCC, which specifically includes the following steps:

[0086] (1) Ni / BaTiO without residual dispersant 3 / NiW homogeneous powder preparation:

[0087] Ni powder, BaTiO 3 Powder and NiW alloy powder are mixed uniformly by a mixer to obtain Ni / BaTiO 3 / NiW homogeneous powder, among them, Ni powder and BaTiO 3 The mass ratio of powder is 1:0.12, and the mass fraction of NiW alloy powder is Ni powder and BaTiO 3 0.5% of the total weight of powder. Ni / BaTiO 3 / NiW homogeneous powder was heat-treated at 300°C for 4 hours in a nitrogen atmosphere rotary furnace to obtain Ni / BaTiO without residual dispersant 3 / NiW homogeneous powder.

[0088] (2) Sanding dispersion:

[0089] Ni / BaTiO without residual dispersant 3 / NiW homogeneous powder, organic solvent and dispersant to adjust to Ni / BaTiO with a solid content of 40% 3 / NiW slurry, wherein the mass fraction of dispersant is Ni / BaTiO ...

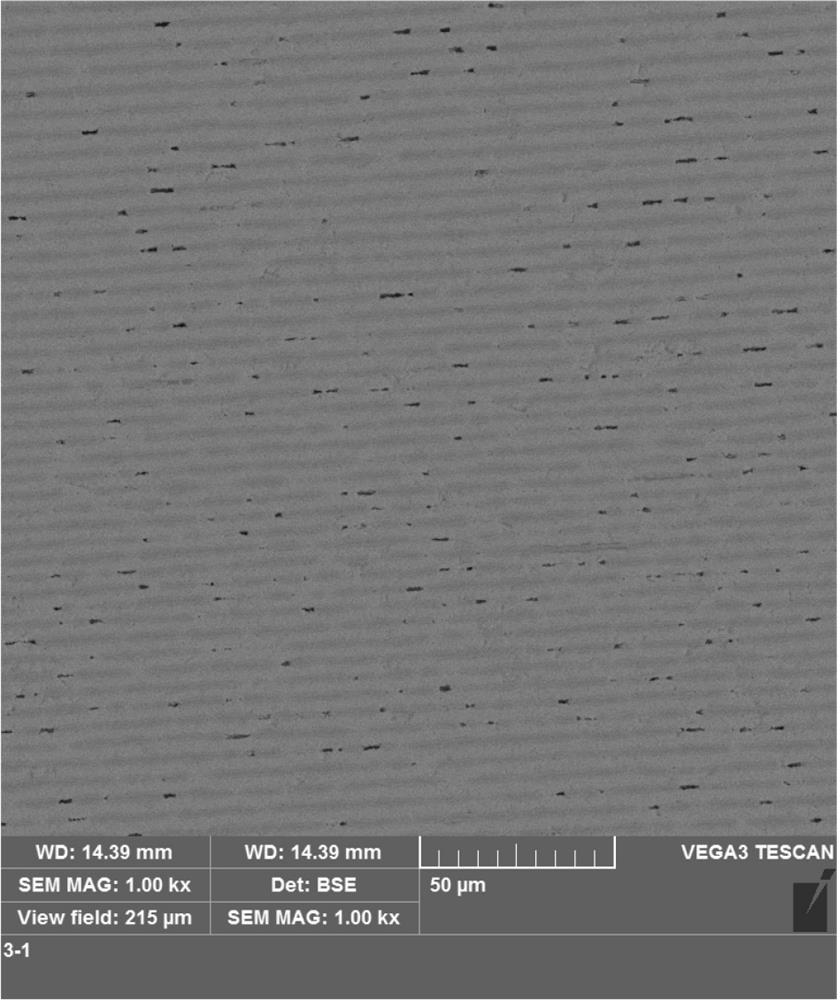

Embodiment 2

[0095] This embodiment prepares a highly dispersible nickel internal electrode slurry for MLCC, which specifically includes the following steps:

[0096] (1) Ni / BaTiO without residual dispersant 3 / NiW homogeneous powder preparation:

[0097] Ni powder, BaTiO 3 Powder and NiW alloy powder are mixed uniformly by a mixer to obtain Ni / BaTiO 3 / NiW homogeneous powder, among them, Ni powder and BaTiO 3 The mass ratio of powder is 1:0.28, and the mass fraction of NiW alloy powder is Ni powder and BaTiO 3 1% of the total weight of powder. Ni / BaTiO 3 / NiW homogeneous powder was heat-treated at 400°C for 3 hours in a nitrogen atmosphere rotary furnace to obtain Ni / BaTiO without residual dispersant 3 / NiW homogeneous powder.

[0098] (2) Sanding dispersion:

[0099] Ni / BaTiO without residual dispersant 3 / NiW homogeneous powder, organic solvent and dispersant to adjust to Ni / BaTiO with a solid content of 50% 3 / NiW slurry, wherein the mass fraction of dispersant is Ni / BaTiO 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com