A Magnetic Ring Assembly Fixture for Terahertz Traveling Wave Tube Periodic Permanent Magnet System

A periodic permanent magnet and assembly fixture technology, which is applied in the direction of electrode system manufacturing, manufacturing tools, workpiece clamping devices, etc., can solve the problems of periodic permanent magnet system structure irregularity, inconvenient, laborious and time-consuming assembly process, etc., to achieve improved magnetic Ring assembly process, improve operability and convenience, and avoid safety risks and hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

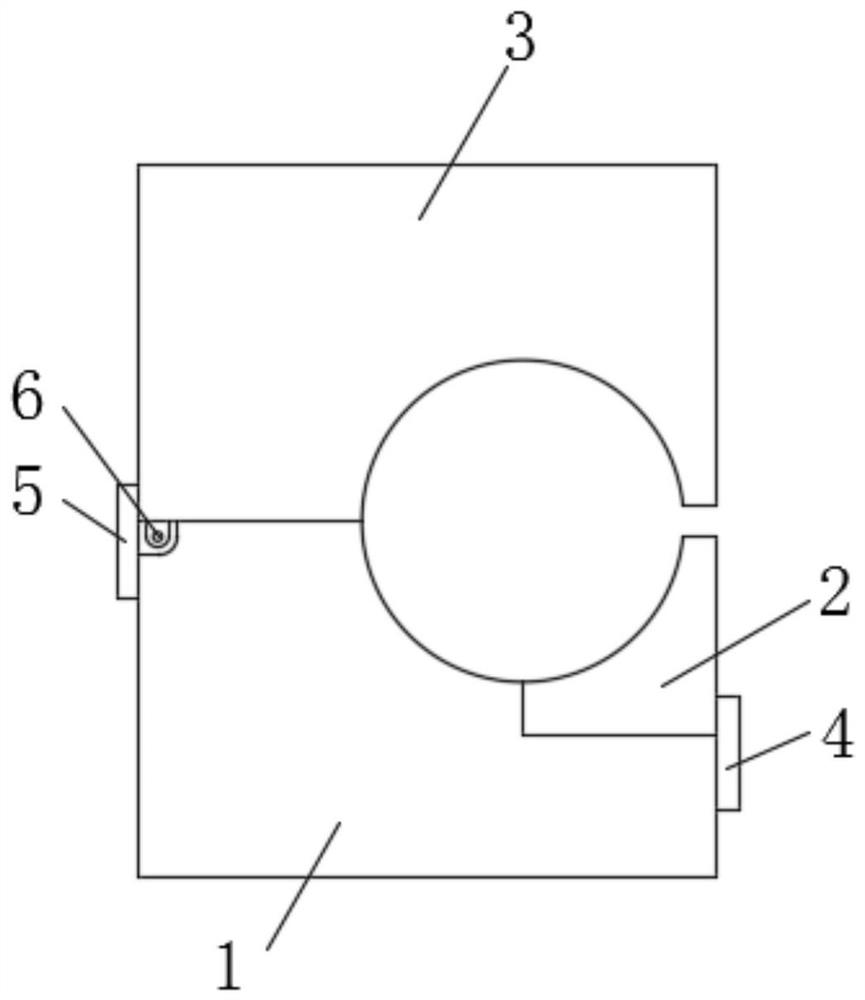

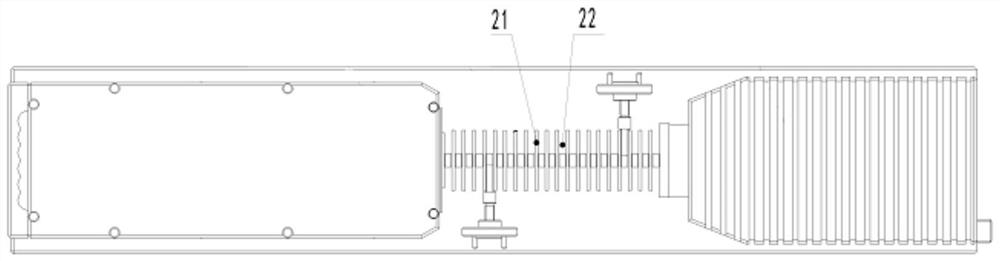

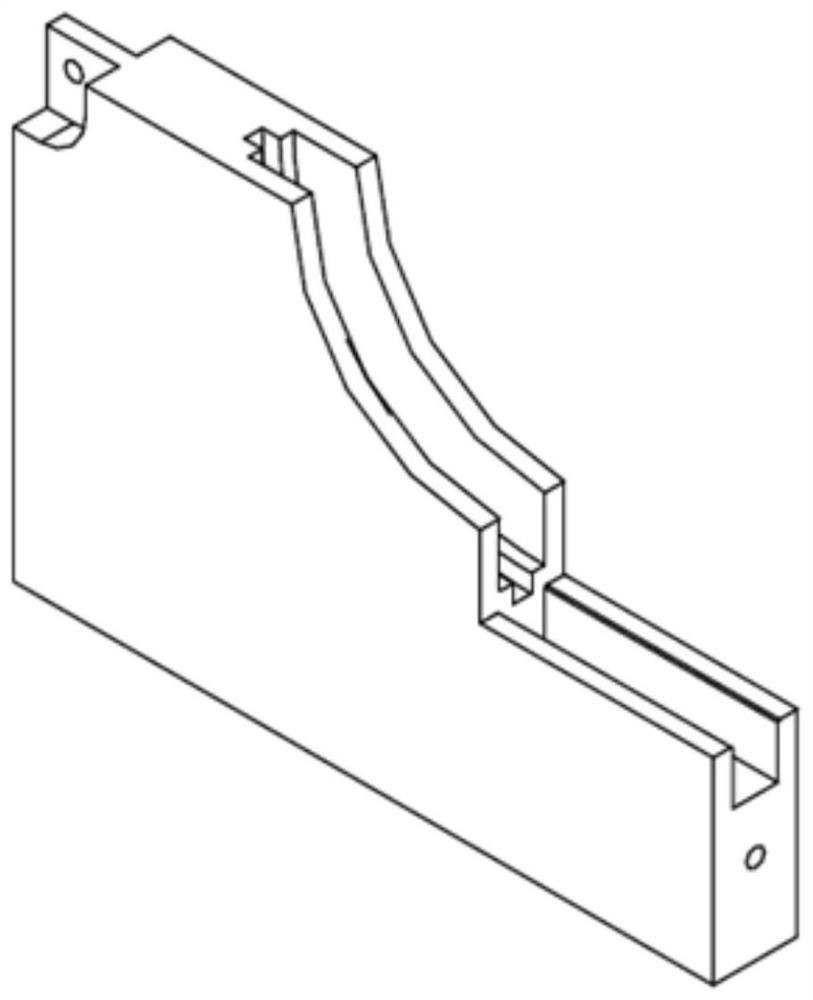

[0035] Such as figure 1 , image 3 , Figure 4 , Figure 5 , Figure 9 , Figure 10 , Figure 11 As shown, in this embodiment, a magnetic ring assembly fixture for a periodic permanent magnet system of a terahertz traveling wave tube includes a base 1 and a lower pole shoe arranged on the base 1 and cooperating with the pole shoe 21 of the terahertz traveling wave tube groove, the lower magnetic ring groove 102 arranged in the lower pole shoe groove and coaxial with the lower pole shoe groove, the lower copper wire groove 101 arranged in the lower magnetic ring groove 102 and coaxial with the lower magnetic ring groove 102, and the lower magnetic ring groove 101 arranged on the base The upper cover 3 on the upper cover 3, the upper pole shoe groove arranged on the upper cover 3 and cooperating with the pole shoe of the terahertz traveling wave tube, the upper magnetic ring arranged in the upper pole shoe groove and coaxial with the upper pole shoe groove The slot 302 and...

Embodiment 2

[0041] On the basis of the above embodiments, in this embodiment, the upper cover 3 is rotatably connected with the base 1 . In this way, the distance between the lower pole shoe and the upper pole shoe can be increased or decreased by the rotation of the upper cover 3 relative to the base 1, and the installation of the terahertz row is facilitated by increasing the distance between the lower pole shoe and the upper pole shoe. The wave tube facilitates the locking of the terahertz traveling wave tube by reducing the distance between the lower pole shoe slot and the upper pole shoe slot, and aligns the two semi-ring magnet blocks. The positional accuracy of the upper cover 3 and the base 1 can also be improved by rotating the upper cover 3 and the base 1 , and the upper cover 3 and the base 1 do not need to be positioned repeatedly during multiple uses, which is beneficial to improve the efficiency of assembly. In this embodiment, other contents not described are the same as th...

Embodiment 3

[0043] On the basis of the above embodiments, in this embodiment, the base 1 is provided with a base connection hole 104, and the upper cover 3 is provided with an upper cover connection hole 303 coaxial with the base connection hole 104. The upper cover connecting hole 303 and the base connecting hole 104 are rotatably equipped with a rotating shaft 6 . In this way, the upper cover 3 can be rotated relative to the base 1 with the rotating shaft 6 as the rotation center, so as to realize the relative rotation function of the upper cover 3 and the base 1 . In this embodiment, other contents not described are the same as those in the foregoing embodiments, so details are not repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com