a hydraulic clutch

A technology of hydraulic clutch and pressure oil, applied in the field of clutch, can solve the problems of difficult processing, high manufacturing cost, and damage to the inner wall of the stator, etc., and achieves the effects of high switching reliability, low manufacturing cost and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

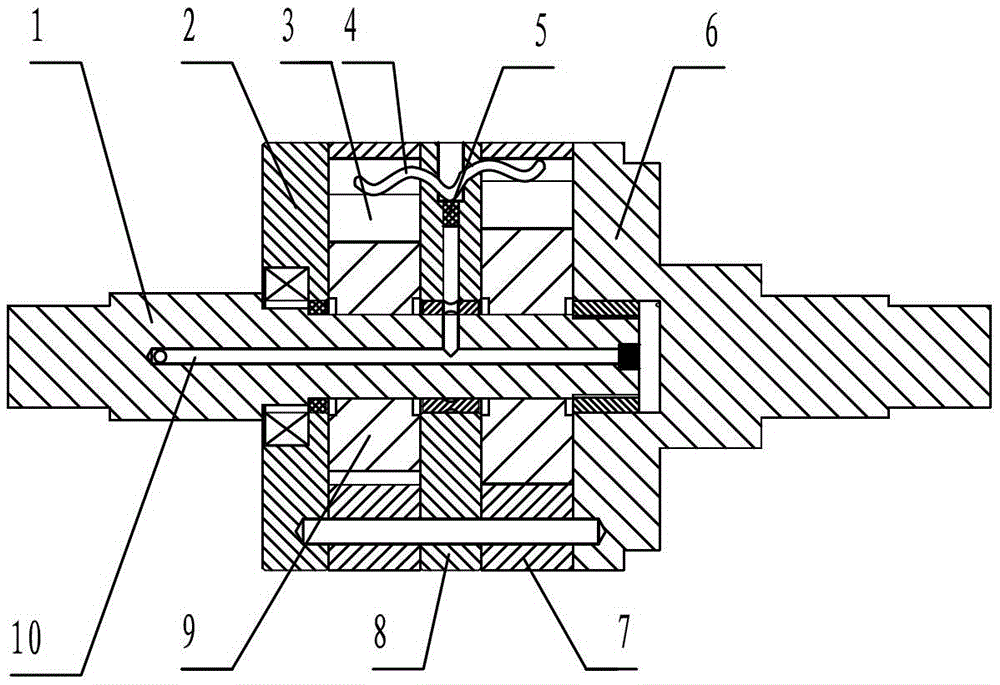

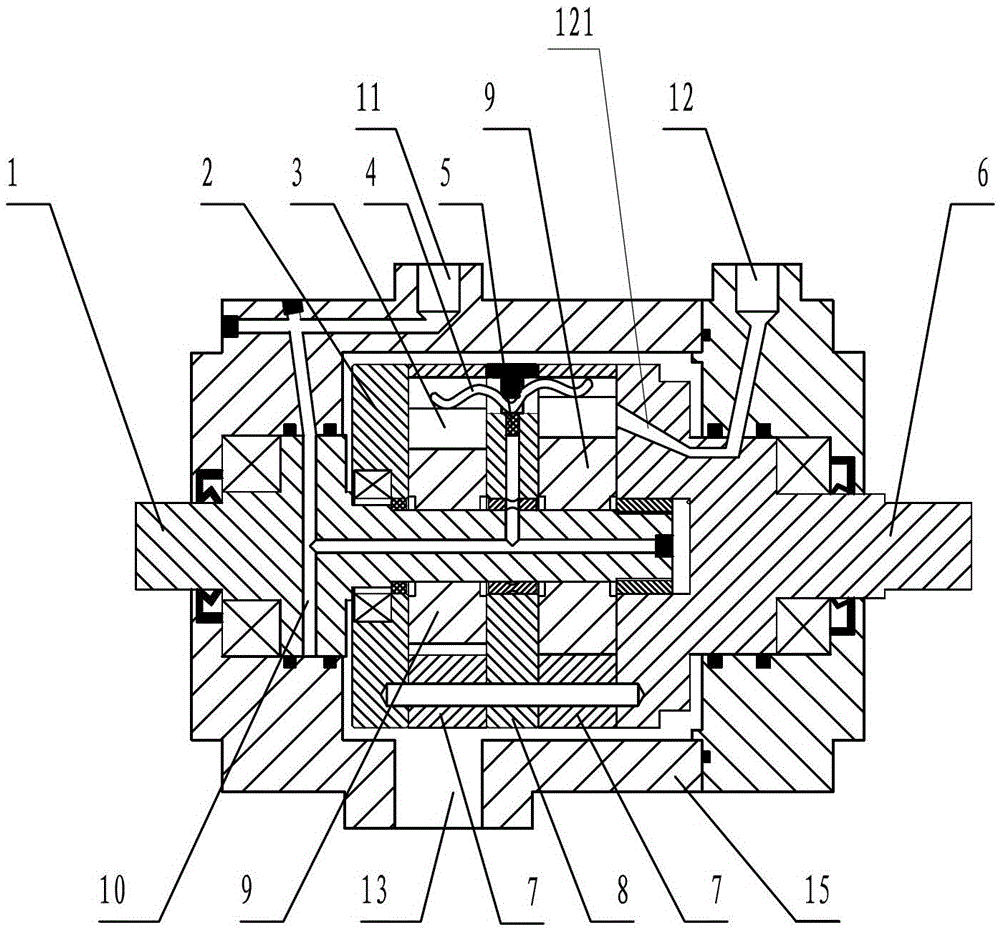

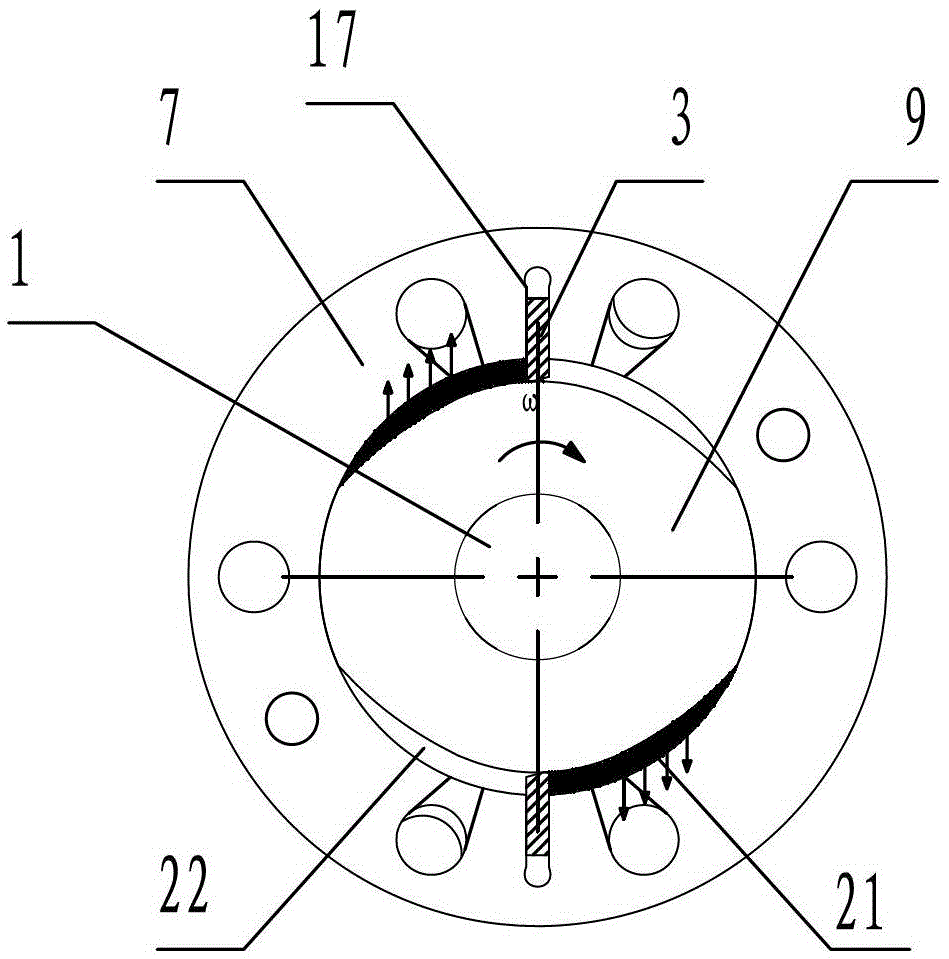

[0021] Embodiment: a hydraulic clutch of the present invention, as attached figure 1 , attached figure 2 , attached image 3 As shown, it includes an input shaft 1 and an output shaft 6 arranged coaxially, and one or more cam-type rotors 9 are arranged on the input shaft 1. Correspondingly, one or more swivel rings 7 are arranged on the output shaft 6. A preferred solution is that each rotor 9 corresponds to one swivel ring 7; the swivel ring 7 has a circular inner cavity, and the rotor 9 is accommodated in the inner cavity.

[0022] A plurality of slots 17 are radially provided on the circumferential wall of the inner cavity of the swivel ring 7, and the vanes 3 are slidably arranged in the slots 17. The root of 3 protrudes out of the slot 17 against the outer peripheral surface of the rotor 9; the cross section of the rotor 9 includes a circular arc segment and a curved segment, and the circular arc segment of the rotor 9 forms a clearance fit with the inner cavity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com