Application of a laser tracker in the measurement of coaxiality of hollow shafts of a large-scale ball mill

A laser tracker and coaxiality measurement technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of difficult operation, poor sight, difficult and accurate positioning of steel wires, etc., and achieve accurate measurement values and measurement accuracy. High, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

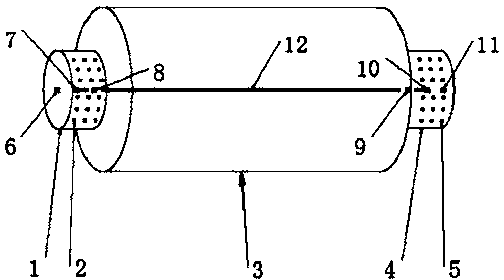

[0019] Such as figure 1 As indicated, familiarize yourself with the laser tracker. The laser tracker uses laser ranging as a means and uses complete spherical coordinates as a measurement system to measure space stationary targets, track and measure moving targets. It generally consists of a laser tracking head, a controller, a user computer, a target ball, and measurement accessories.

[0020] On-site erection of instruments: When determining the erection position of the instrument, strive to meet the data collection at all measurement positions. Because external vibration will affect the measurement accuracy, the position of the instrument is required to be a fixed platform, preferably on a concrete foundation, and there should be no cranes or cars around.

[0021] Turn on the instrument: due to instrument handling, long-term use, bumps, collisions, etc., the measurement accuracy of the laser tracker is very different before and after calibration. Therefore, the instrumen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com