Cutter performance test bench

A technology of cutter and test bench, which is applied in the testing of machine/structural components, instruments, measuring devices, etc., can solve problems such as difficulty, low data accuracy, and widely varying field planting conditions, and achieves the effect of solving adaptability problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

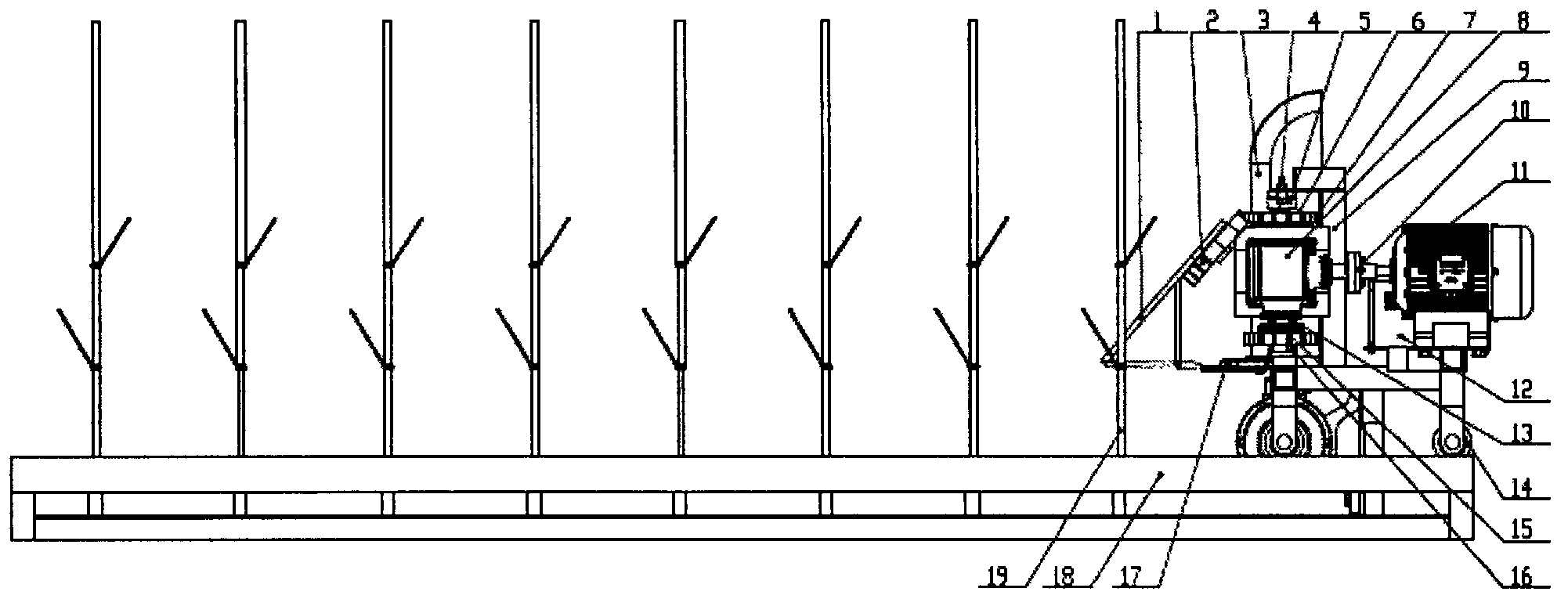

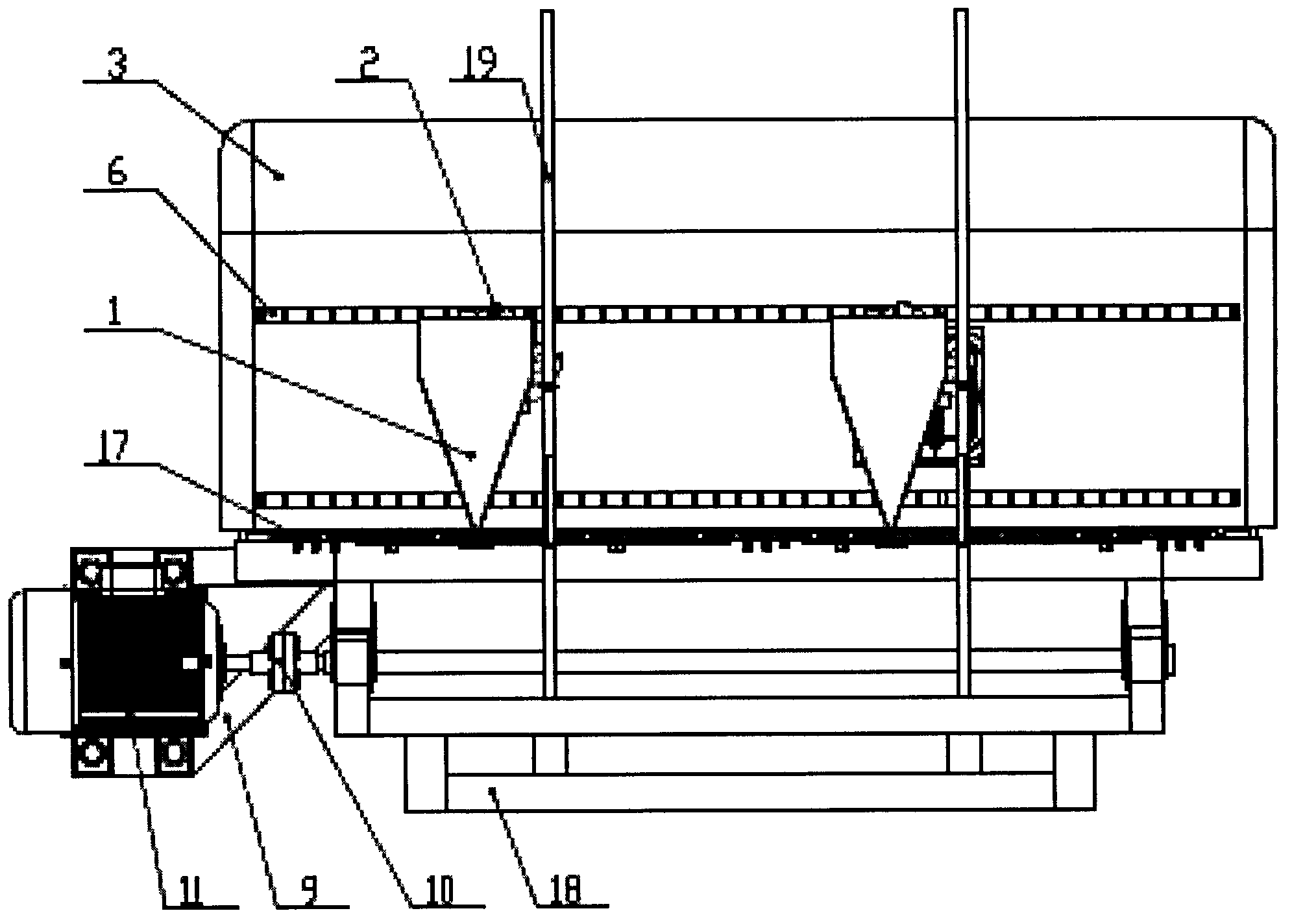

[0013] exist figure 1 Among them, the described cutter performance test bench includes a frame (9), which is characterized in that the frame (9) is also equipped with a crop divider (1), a reel (2), Baffle plate (3), bearing seat (5), the stand of cutter assembly (17), reducer (8), crank slide frame mechanism (16), the both sides of frame (19) are provided with motor (11 ), the bottom of frequency converter (12), frame (9) is provided with the installation notch of four ground wheels (14), and guide rail (18) is used for the positioning groove of inserting grain seedling (19) on the guide rail (18).

[0014] exist figure 1 In the illustrated embodiment, the slider crank mechanism includes a slider crank, a sleeve and a slide frame on the cutter assembly, which converts the rotary motion of the slider crank into the reciprocating linear motion of the movable blade of the cutter assembly.

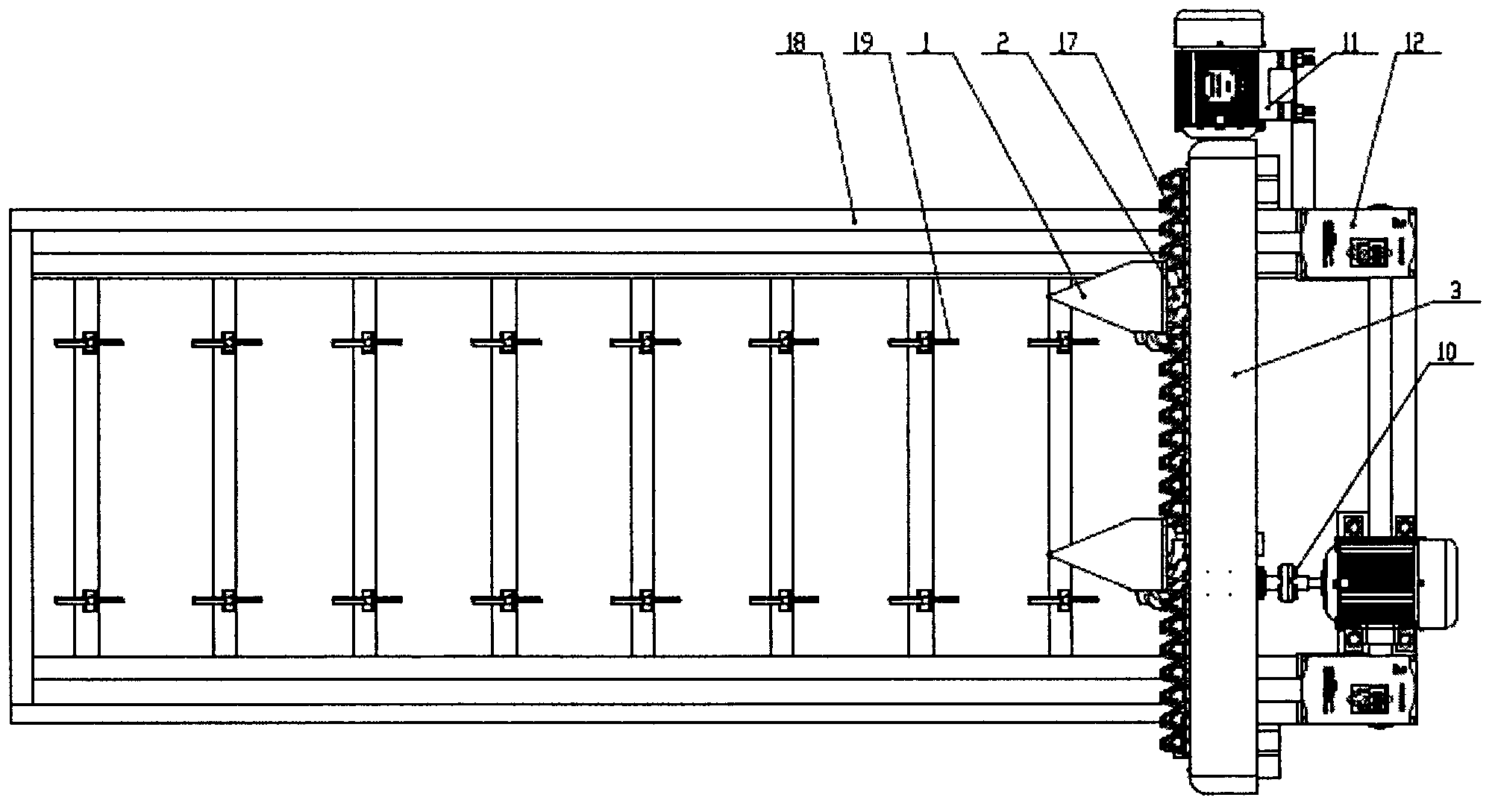

[0015] exist figure 2 In the shown embodiment, the cutter assembly includes a knife h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com