Method for verifying engine model in off-line way

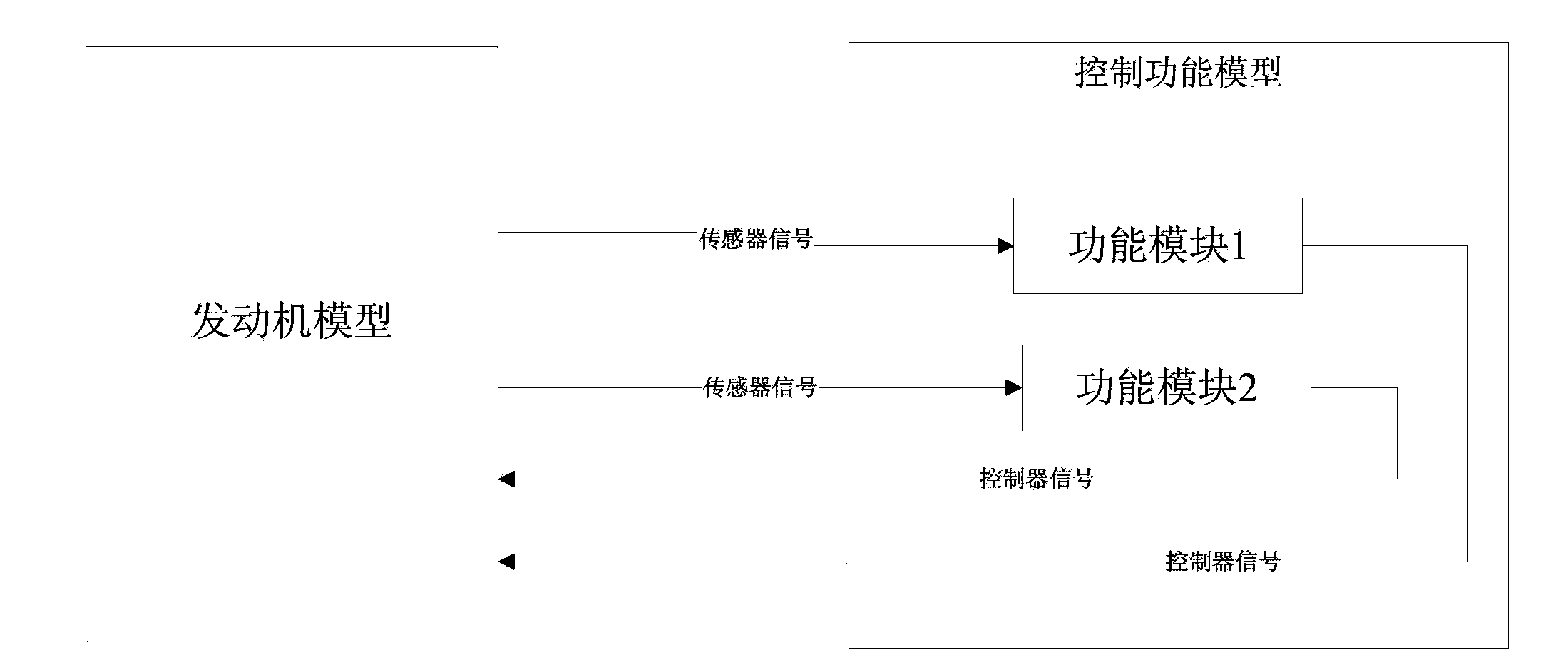

An engine and model technology, applied in simulators, instruments, control/regulation systems, etc., can solve problems such as verification result deviation, design error, uncontrollable execution sequence, etc., and achieve the effect of avoiding result deviation and design error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

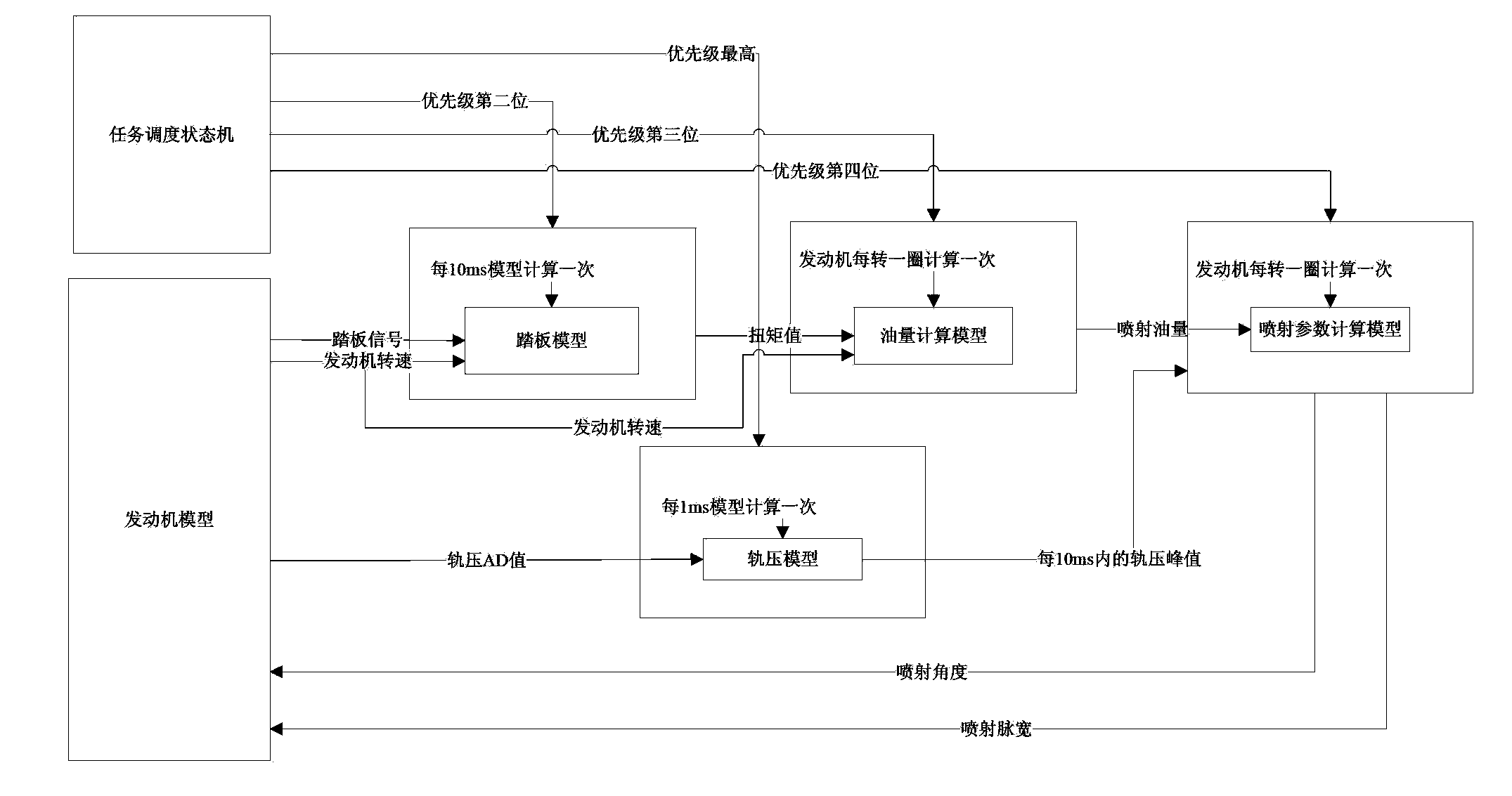

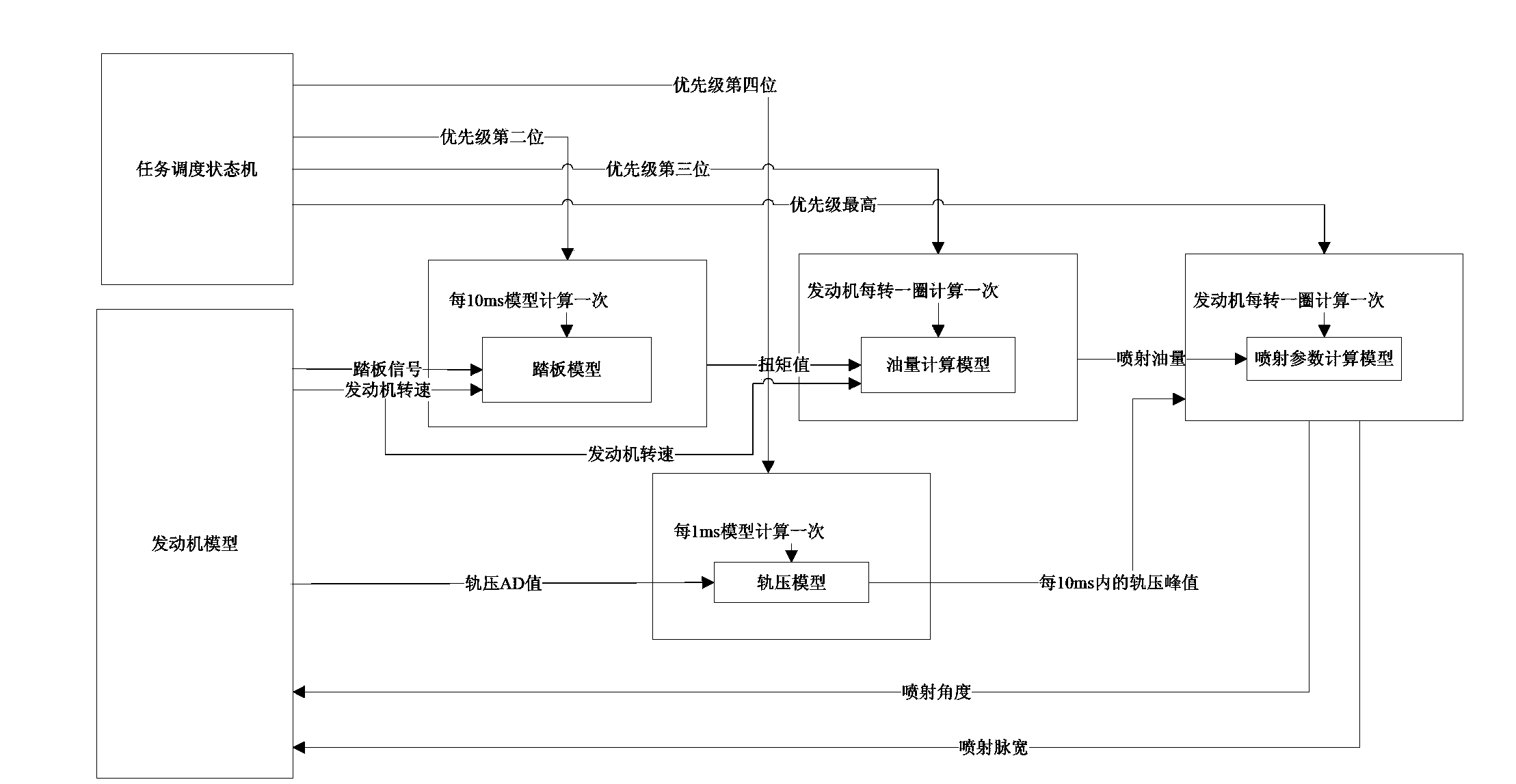

[0034] like figure 2 As shown, adopting the method for offline verification of the engine model of the present invention, it is assumed that the engine control function has four control modules: a rail pressure module, a pedal module, a fuel volume calculation module, and an injection parameter module;

[0035] Define the execution sequence for each control module according to the actual control requirements of the engine:

[0036] The execution timing of the rail pressure module is: data is sampled once every 1ms, and the peak values of the current 10 values are taken every 10ms;

[0037] The execution timing of the pedal module is: data is sampled and calculated every 10ms;

[0038] The execution sequence of the fuel quantity calculation module and the injection parameter module is: the data is calculated once every revolution of the engine.

[0039] Set metering trigger conditions for the above four functional modules: trigger the rail pressure module every 1ms, trig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com