Profile section moulded by multi-injection moulding and forming a seal or a moulding for the body of a motor vehicle, and method for manufacturing same

A technology of multiple injection molding and contour parts, applied in the field of contour parts, can solve problems such as difficult assembly, incorrect operation of functional parts, high friction coefficient, etc., and achieve good sealing and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

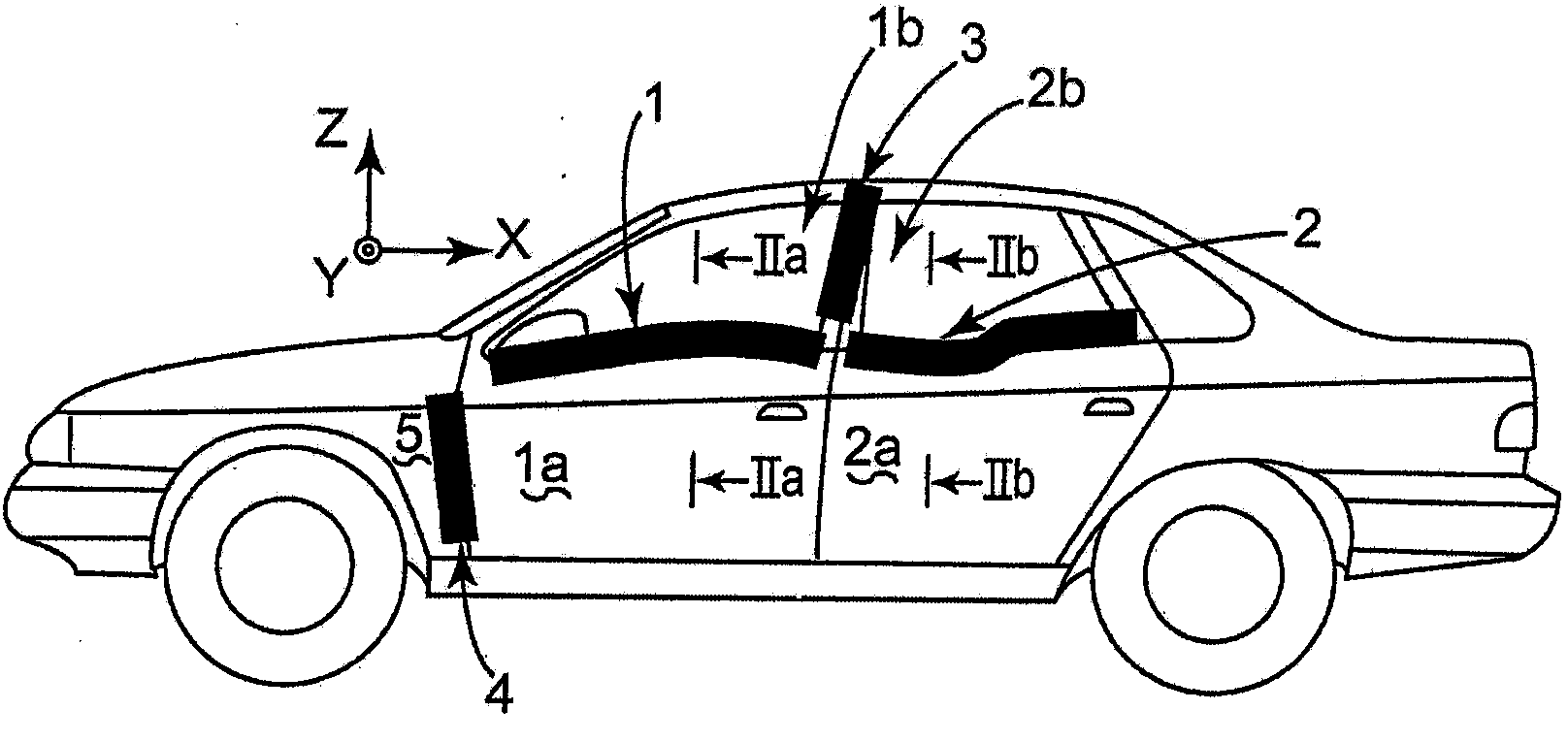

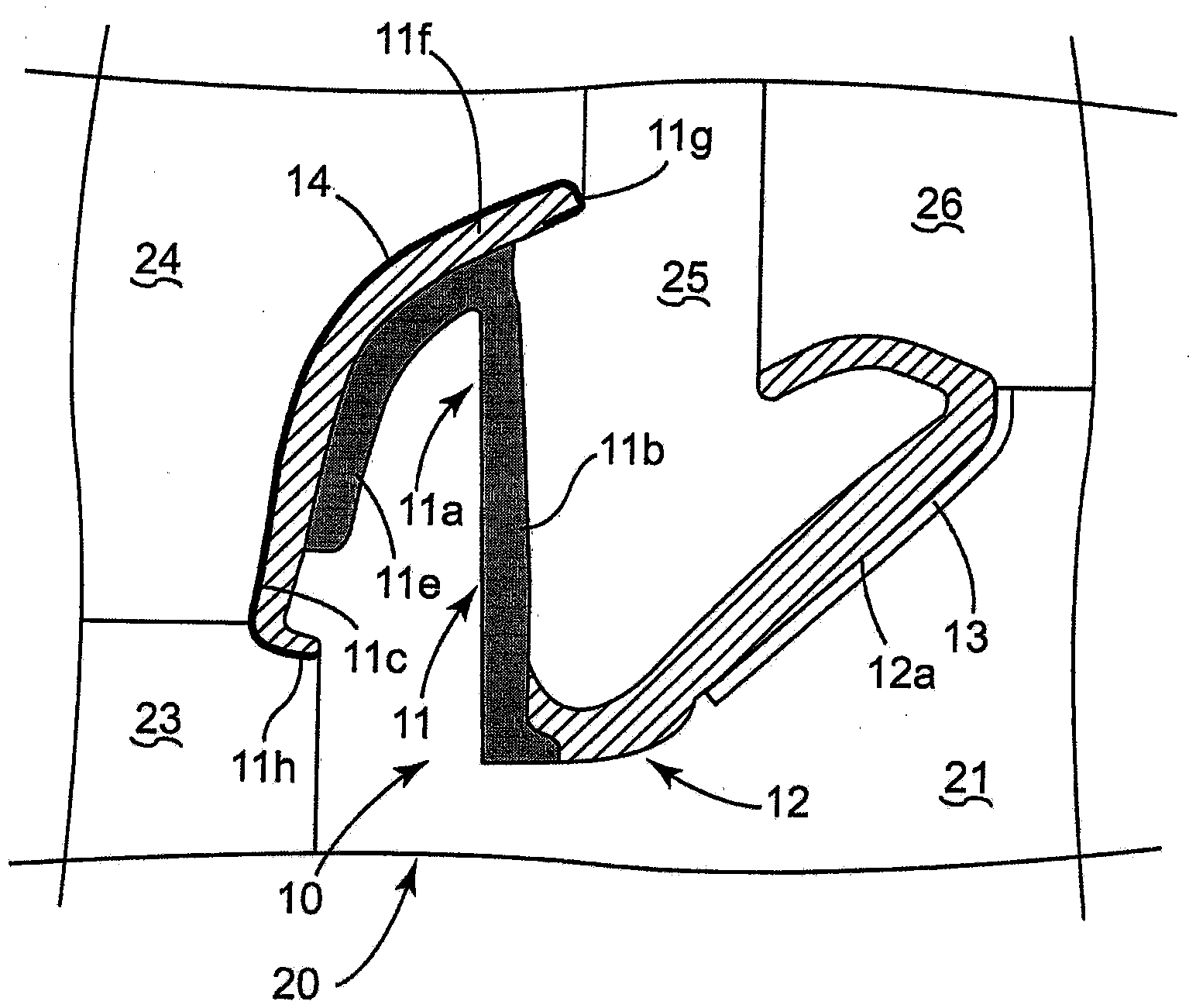

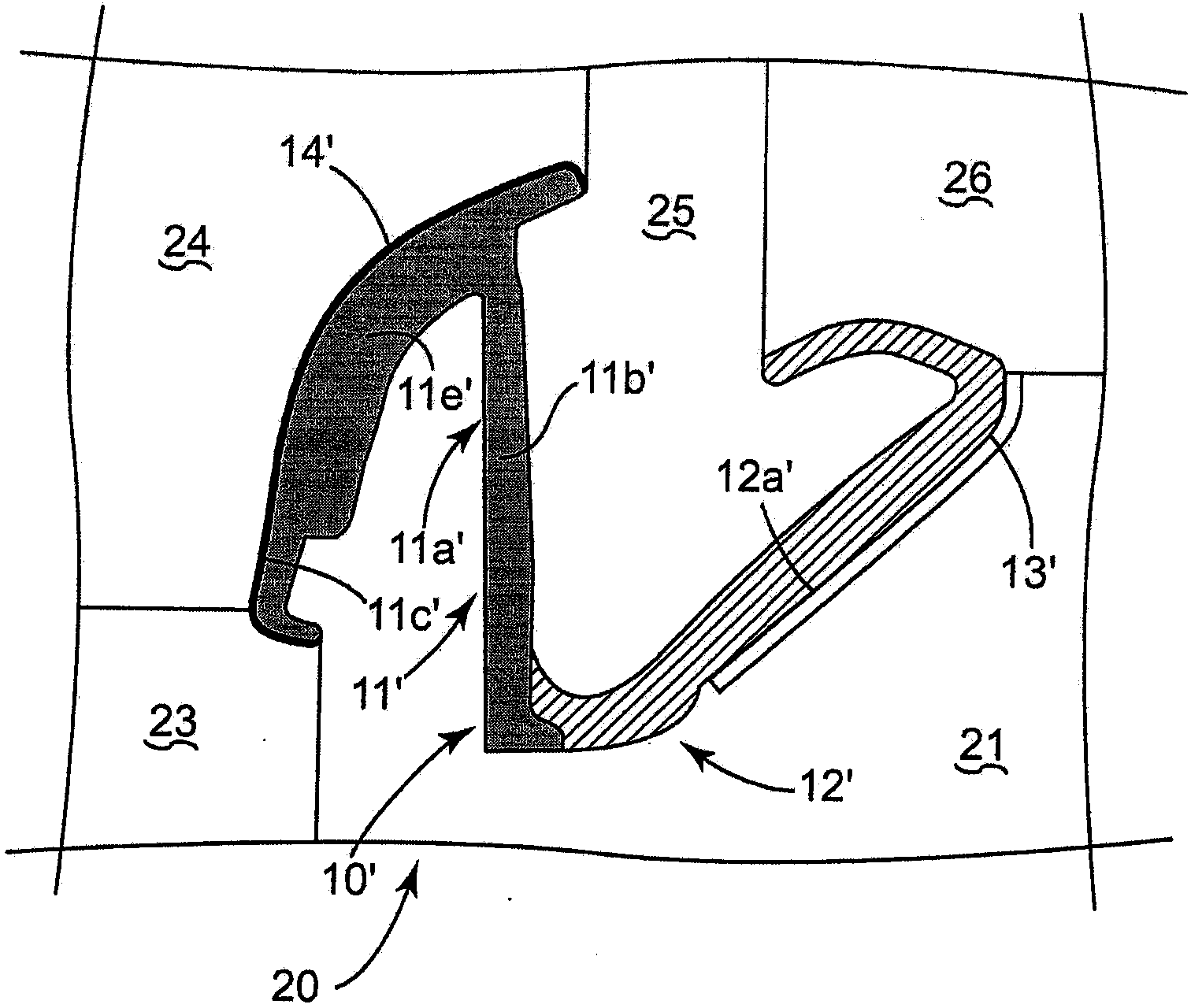

[0085] In the following, the qualifiers "axially inner" and "axially outer" will be used in the usual way to designate the position of the profile element towards the inside and towards the outside, respectively, along the axis Y of the width of the vehicle (this transverse horizontal direction Y is referred to as defined as being perpendicular to the XZ plane defined by the longitudinal horizontal direction X and the vertical direction Z). To visualize these directions X, Y and Z, refer to figure 1 , Figure 4 with Image 6 .

[0086] Such as figure 1 As shown in , in the case of seals, for example, the profile according to the invention can form trim inserts or seals at various locations 1, 2, 3 and / or 4 on the body of a motor vehicle in order to withstand The wear coat provides a sealed contact between the body support and another element of the vehicle, such as a fixed sunroof or lift glass. Each of areas 1 and 2 shows the profiles constituting the inner and outer fri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com