Breaking prevented bottle

A bottle and anti-drop technology, applied in feeding bottles, etc., can solve the problems of crisis baby’s healthy growth, glass material is easy to slip, glass feeding bottle falls to the ground, etc., to prevent scratches or burns, improve use safety, Guaranteed cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

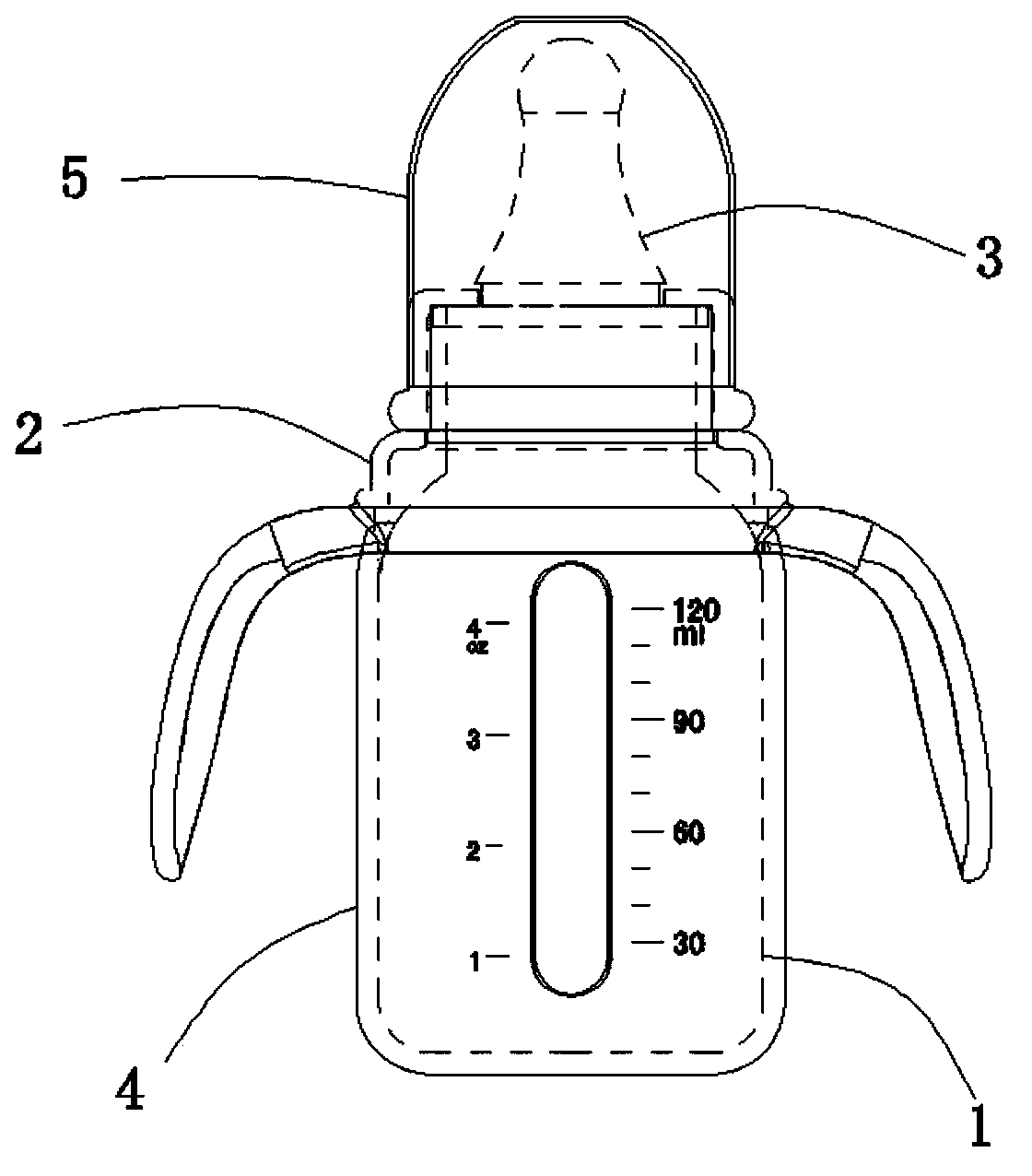

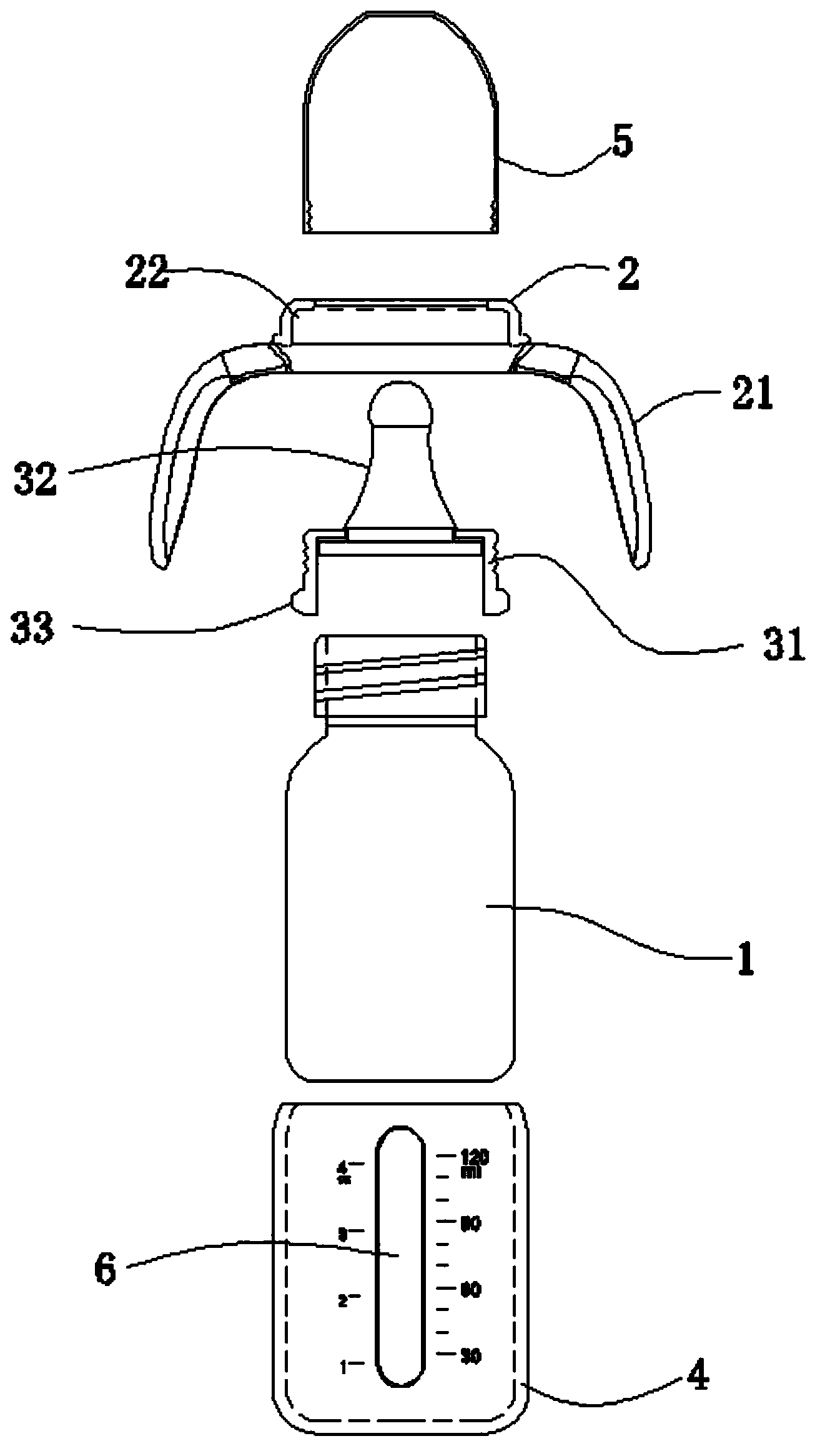

[0020] see figure 1 with figure 2 , a kind of drop-proof bottle provided by this embodiment, it comprises a container 1, a cover body 2 and a pacifier 3, and this pacifier 3 is arranged on the container 1 through the cover body 2, and the outer surface of the container 1 A protective sheath 4 is sheathed, and an isolation cover 5 capable of covering the teat 3 is provided on the nipple 3 . An isolation cover 5 is provided to prevent the pacifier from contacting foreign matter, and ensure the pacifier is clean, which is beneficial to health.

[0021] The protective cover 4 is a silicone cover with an upward opening, and the opening of the silicone cover is gradually closed. A transparent or translucent vertical window 6 is provided on the silicone sleeve, and at least one measuring scale mark is provided on one side of the vertical window 6 . In this embodiment, the left side of the vertical window 6 is provided with an ounce measurement scale mark, and the right side is sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com