Laser cutting carrier

A technology of laser cutting and laser cutting machine, which is applied in the direction of laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems that the multi-faceted cutting requirements cannot be met, and achieve the effects of simple structure, improved efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

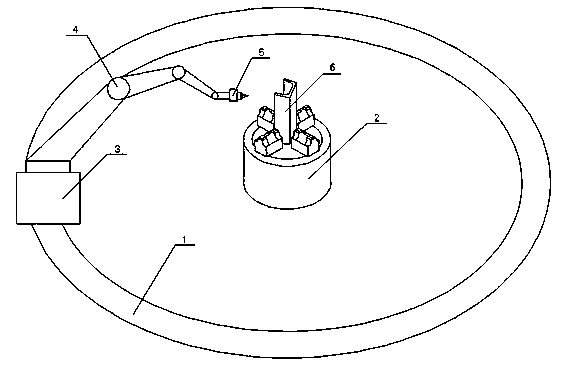

[0012] See attached figure 1 , the present invention proposes a laser cutting carrier, including a laser cutting machine 3, the laser cutting machine 3 is placed on a circular track 1, a tooling fixture 2 is placed in the center of the circular track 1, and the laser cutting machine 3 is placed along the circular track 1. The shaped track 1 rotates 360° around the fixture 2. The laser cutting machine 3 adopts a manipulator structure, and the fixture 2 is a chuck claw structure, which can rotate 360° by itself.

[0013] When in use, first fix the channel steel 6 of the workpiece to be processed on the fixture 2, adjust the laser cutting machine according to the c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap