Numerically controlled lathe with dedusting function

A CNC lathe and functional technology, applied in the field of CNC lathes, can solve problems such as processing result errors, achieve the effects of reducing processing errors, facilitating chip removal, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

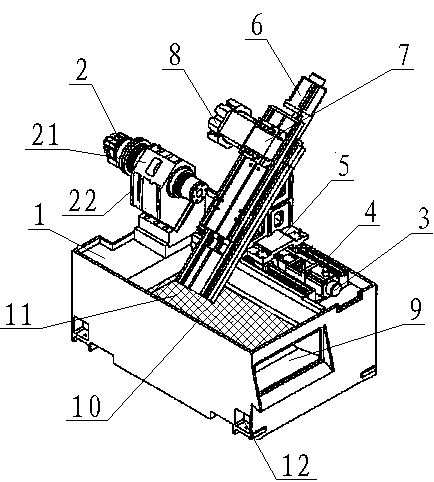

[0016] see figure 1 As shown, a CNC lathe with dust removal function includes a bed 1, a spindle assembly 2 arranged at the upper left end of the bed 1, a Z-axis assembly 3 fixedly arranged on one side of the spindle assembly 2, and the Z-axis assembly 3 The saddle 5 connected with the linear slide rail 4 on the upper part, and the X-axis assembly 6 arranged on the saddle 5, a slide plate 7 is installed on the X-axis assembly 6, and a tool rest 8 is installed on the slide plate 7, the described The bed 1 is provided with a chip storage tank 9, and the chip storage tank 9 is provided with an opening 10, and the opening 10 is connected with the upper surface of the bed 1, and a filter grid 11 is installed in the chip storage tank 9, and the bed Body 1 outside is provided with the dust suction groove 12 that is connected with chip storage groove 9 pipelines.

[0017] The main shaft assembly 2 is provided with a main shaft seat 21 , and the outer surface of the main shaft sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com