Blow moulding machine

A technology of a plastic container and a locking mechanism, which is applied in the special transmission machinery of the glass blowing machine, etc., can solve the problems of complex technology and poor durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

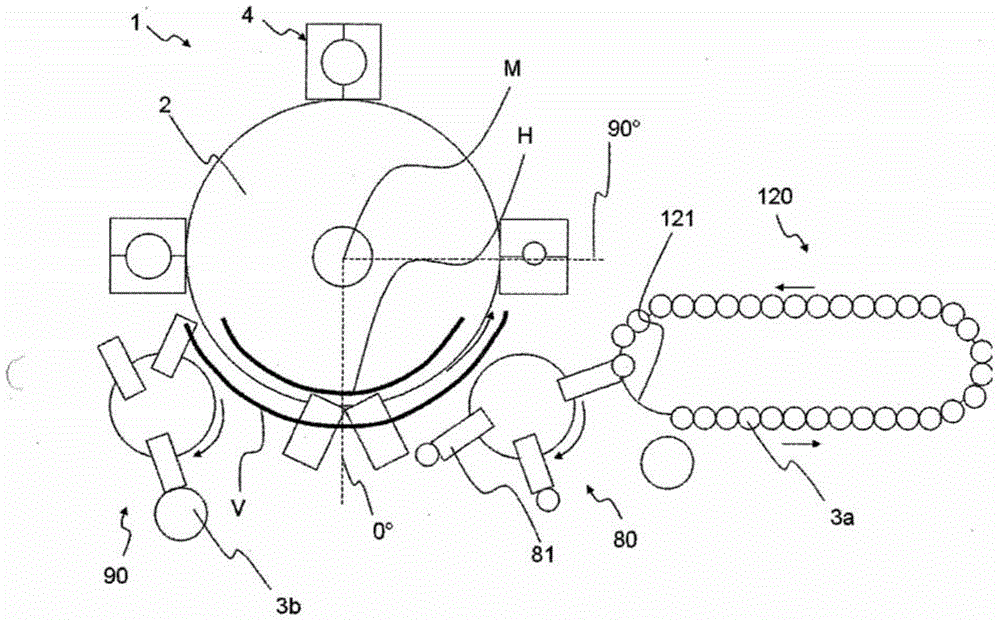

[0062] figure 1 A plant 1 for the production of plastic containers 3b according to the invention is shown. In the present example, the plastic pre-forms 3 a are first transported on a transport chain 121 and heated by a heating device 120 . The plastics material pre-forms 3 a heated in this way are then taken up by a feed star wheel 80 and transported to a plurality of forming stations 4 . In the present example, said feed star wheel 80 has a plurality of arms 81 which are rotatable relative to the star wheel and which in any case are provided with support elements ( not shown), such as clips, are used to support the plastic preform.

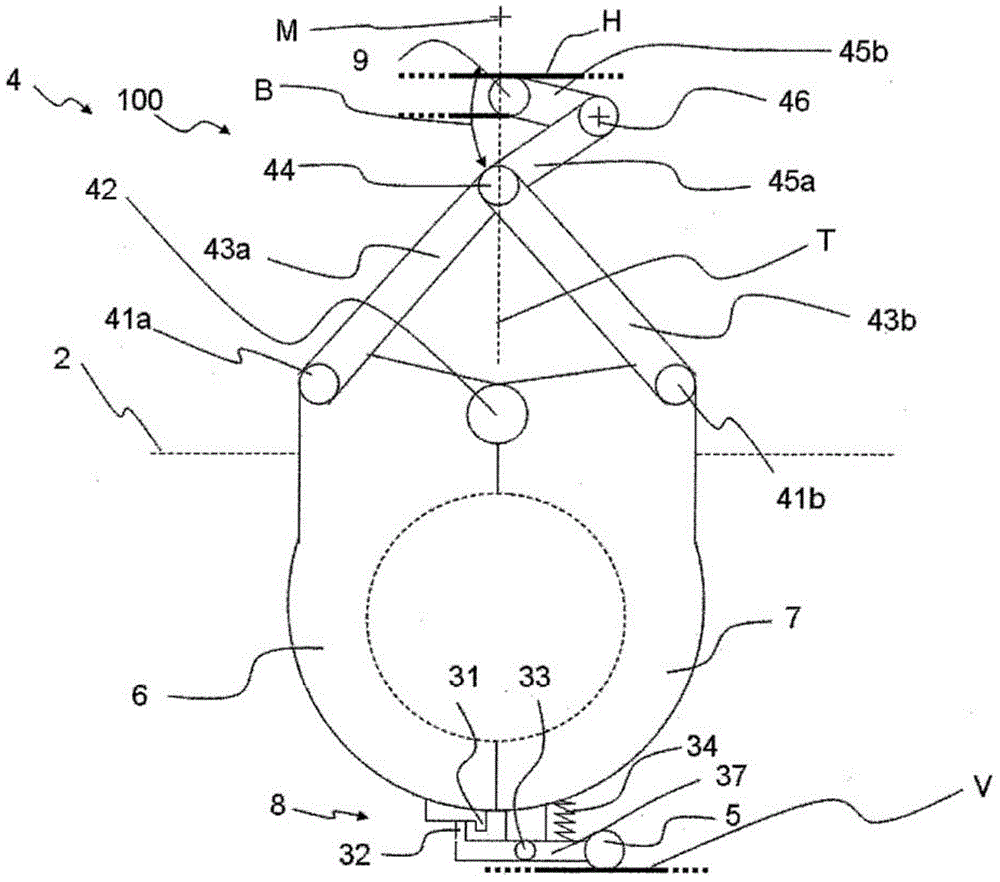

[0063] Reference numeral 2 relates to a rotatable carrier on which a plurality of forming stations 4 (only four are shown here in the figure) are arranged. In the present example, these forming stations 4 have a first blow mold carrier part 6 and a second blow mold carrier part 7 . The blow-molded parts are arranged on these carrier parts so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com