Sliding contact type electromagnet conveying belt

A technology of electromagnets and conveyor belts, which is applied in the field of conveyor belts, and can solve the problems of common conveyor belts such as omissions in transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

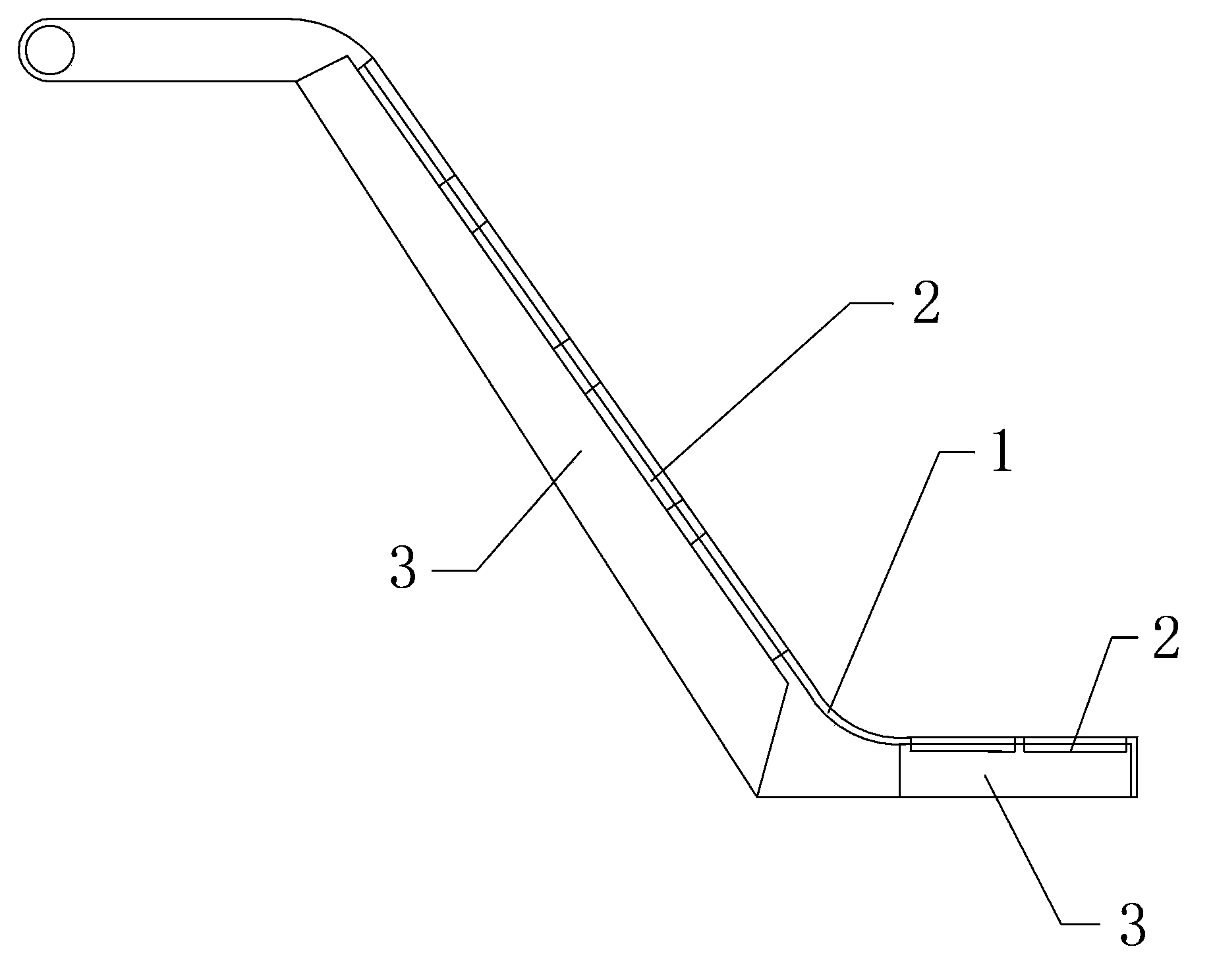

[0009] Such as figure 1 A sliding-contact electromagnet conveyor belt is shown, the lower end of the conveyor belt is fixed with an electromagnet layer 1; The power supply slide rail 3 at the lower end of the conveyor belt realizes cooperative power supply; the power supply slide rail 3 is not provided at the end of the conveyor belt;

[0010] The present invention having adopted the above-mentioned technical scheme absorbs the filtered iron scraps on the surface of the conveyor belt through the magnetic force of the electromagnet, and the power supply of the electromagnet realizes the power supply with the slider installed on the electromagnet and the power supply slide rail at the lower end, so that It is possible to limit the travel of the conveyor belt with magnetic force by setting the formation of the power supply slide rail.

[0011] The above description is only a preferred embodiment of the present invention, and does not limit the present invention in any form. Alth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com