Locking combined hook ring

A technology of combining hooks and shackles, applied in the direction of pipeline supports, pipes/pipe joints/pipes, mechanical equipment, etc., it can solve the problems of not being able to install at a large angle or even vertically, and the hooks cannot be locked and fixed, so as to achieve convenient combination and flexible use. Safety and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

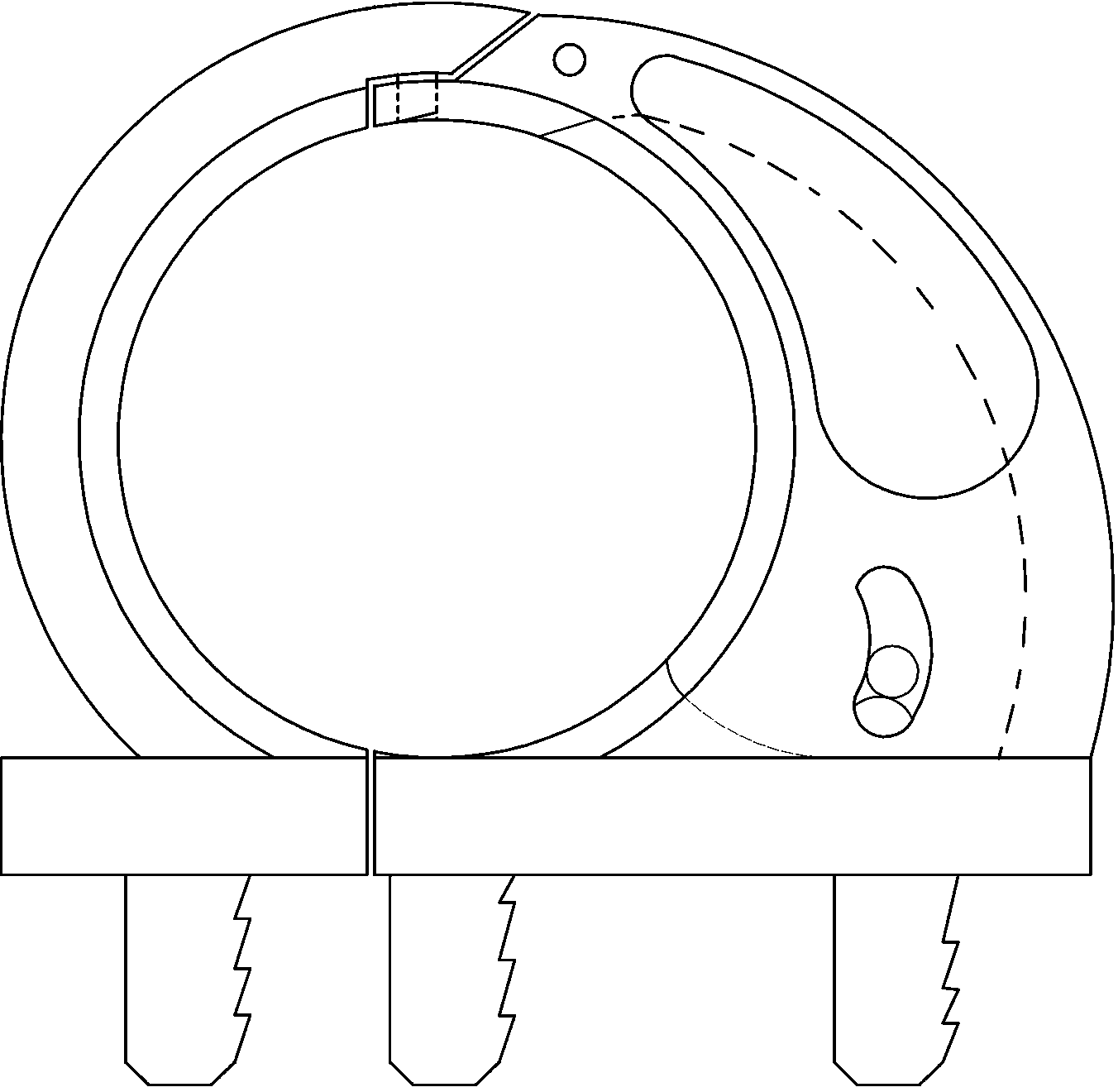

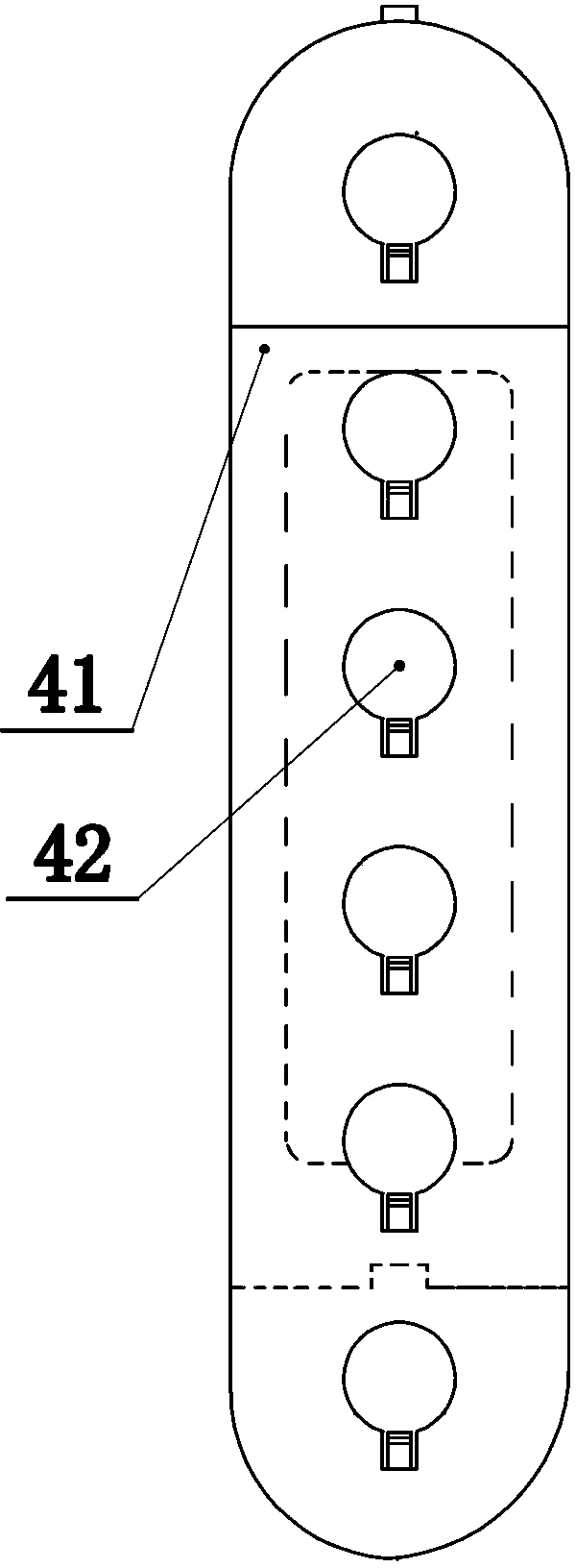

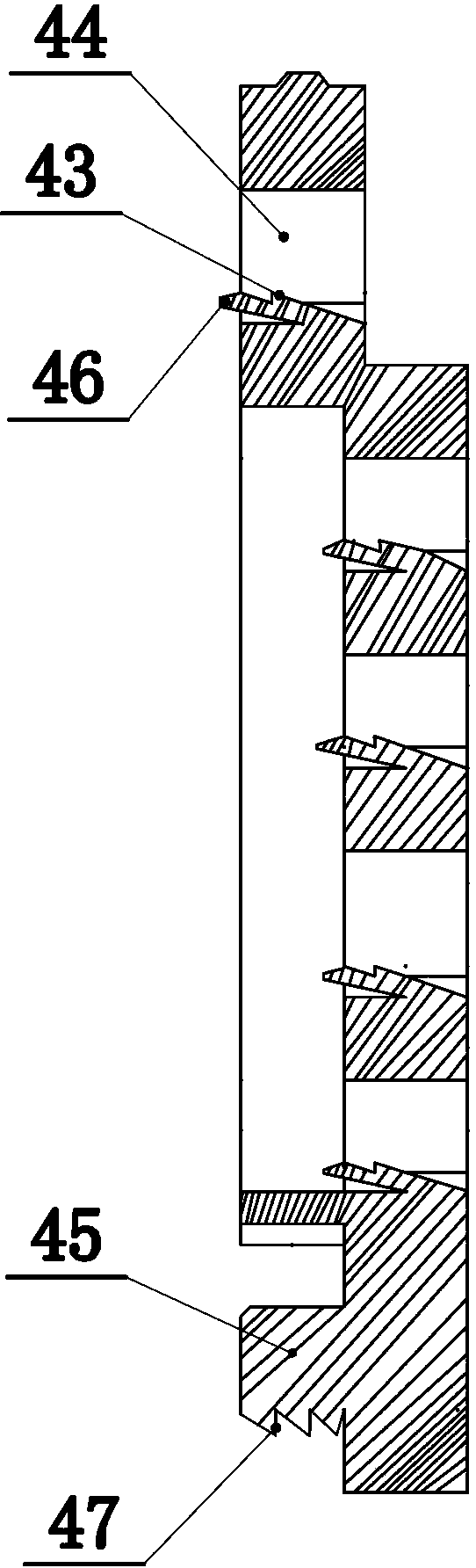

[0028] Hook between the hooks 41. Such as Figure 10-13 As shown, when multiple hooks are hooked, if there are many hooks, the first hook 41 is fixed through the through hole 44 on the hook 41, and the through hole 44 of the next hook 41 is inserted into On the horizontal post 45 on the upper hook body 41, press down the elastic teeth 43 in the through hole 44 on the lower hook body 41. The elastic teeth 43 in the through hole 44 and the horizontal post 45 of the previous hook body 41 are pressed down. The anti-dropping teeth 47 cooperate to prevent disengagement and complete the connection between the hooks; when disassembling, the pressing table 46 needs to be pressed down to separate the anti-dropping teeth 47 from the elastic teeth 43, and directly pull out to complete the disassembly. Hook body 41.

[0029] The locking block 21 is fixedly installed in the lower closure buckle 31. Such as Picture 9 , The locking block 21 and the lower closure buckle 31 are installed. Inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com