Work device

一种工作器械、工具的技术,应用在仪器、切割工具、机械设备等方向,能够解决操作者疲劳等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

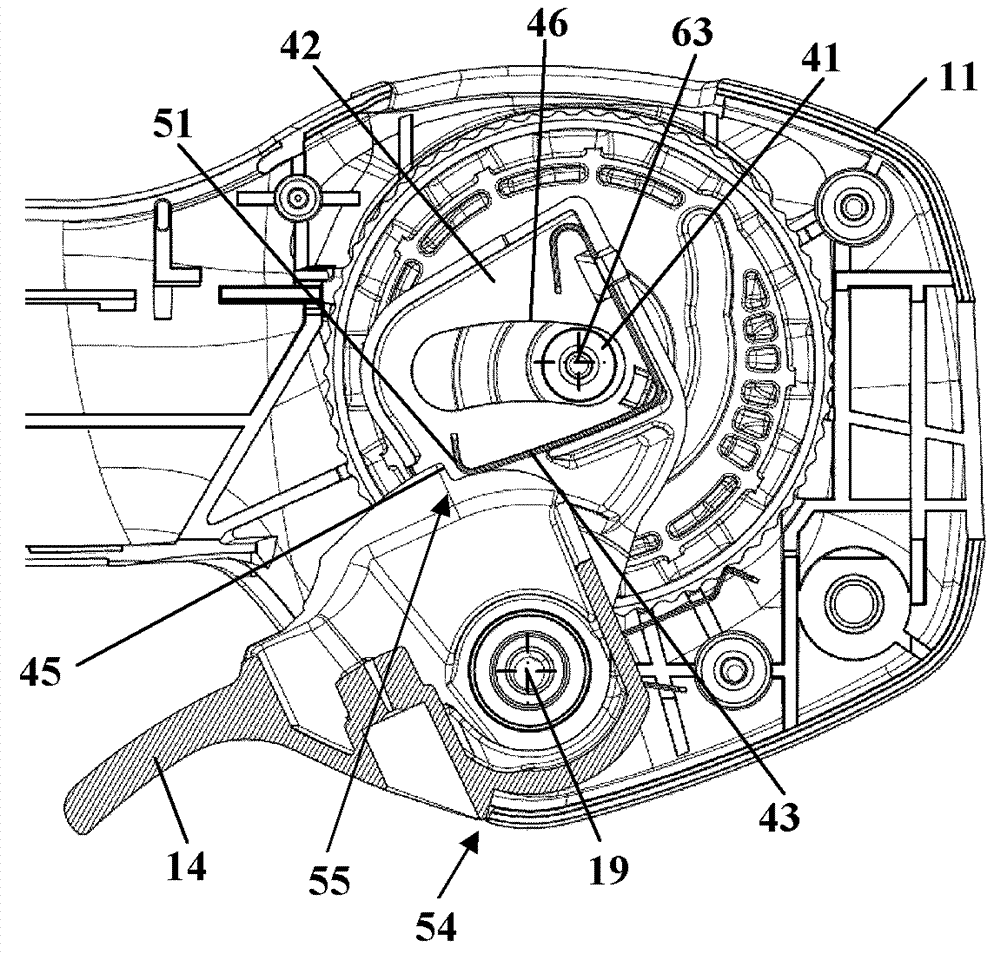

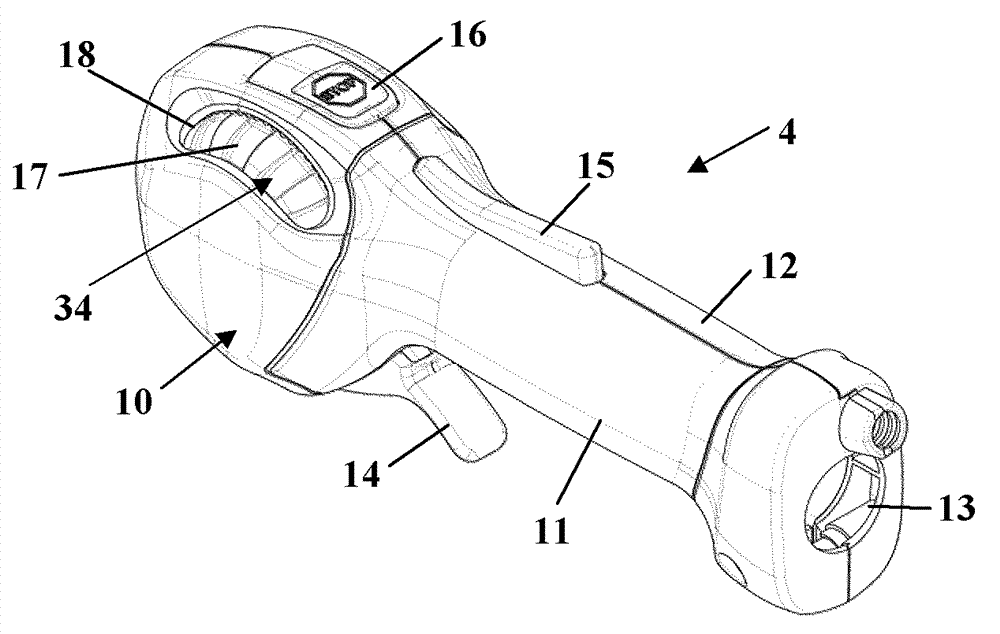

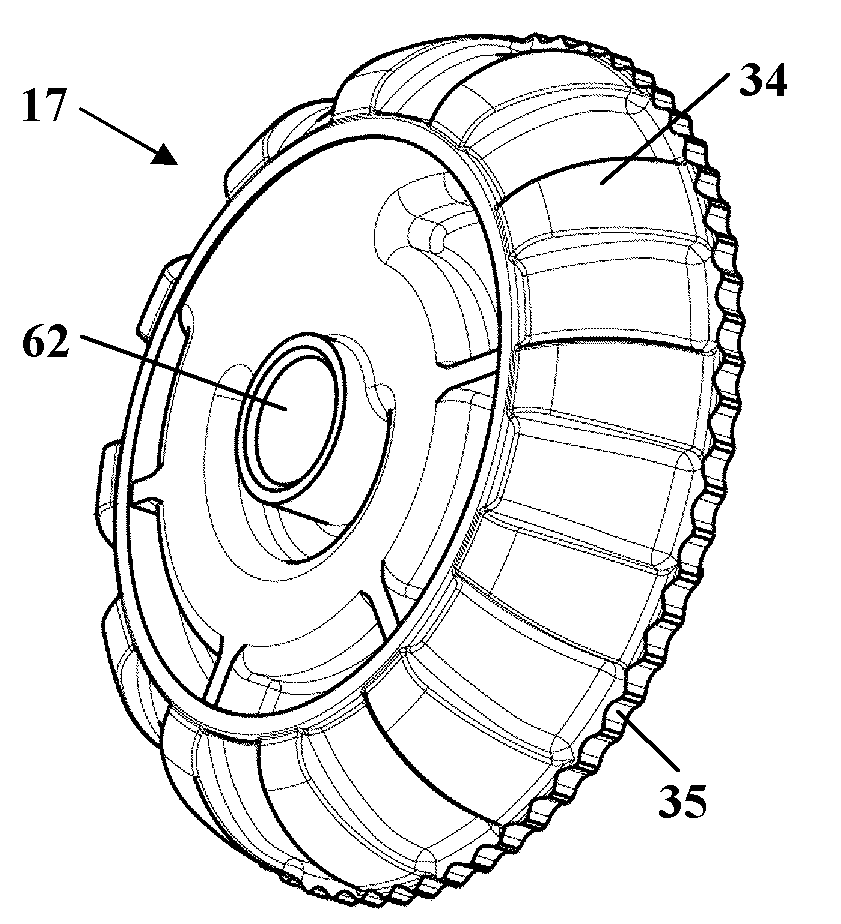

[0036] figure 1 A hand-held power tool, a field trimmer 1 , is shown as an example for a power tool. However, the design of the intermediate stop described below can also be used advantageously in other work implements, in particular in other hand-held work implements, especially in sprayers (Sprühgeröt), blowers (Blasgeröt), hedge trimmers ( Heckenschere), olive harvesters (Olivenernter) or similar objects. For blowers and sprinklers, the means are fan impellers (Geblöserad) which deliver the working air flow. For harvesting devices such as olive harvesters or the like, the tools are formed by moving fingers, hooks or the like that act into the tree or shrub.

[0037] The trimmer 1 has a motor housing 2 in which the figure 1 Drive motor not shown. The motor housing 2 is connected via a guide tube 3 to a mowing head 6 , from which a cutting wire 7 protrudes. The cutting head 6 is driven in rotation. The flight circumference of the cutting wire 7 is partially covered by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com