Sieving device of dry-process granulating machine

A technology of dry granulation and sieving, which is applied in the fields of filtration and sieving, solid separation, chemical instruments and methods, etc. It can solve the problems of poor purity of finished granules, high fine powder rate of finished products, and low sieving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

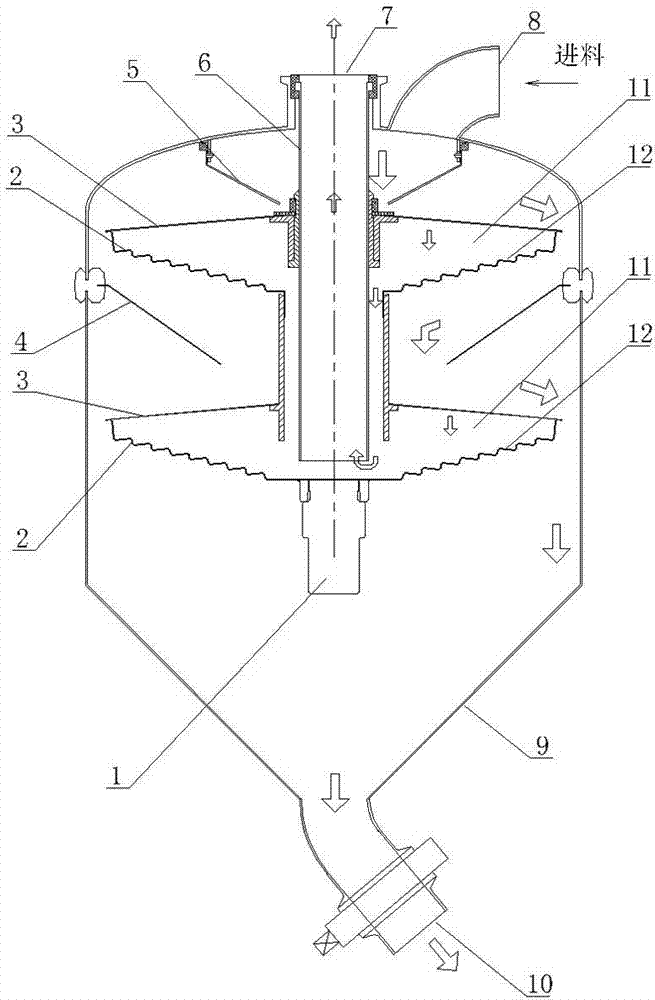

[0011] The accompanying drawings represent the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

[0012] As shown in the figure, the sub-sieving device of the dry granulator of the present invention includes a sub-sieve bucket 9, a sieve plate 3 and a powder receiving pan 2, and the barrel wall of the sub-sieve bucket 9 is provided with a feed inlet 8 and a fine powder outlet. Feed port 7 and finished product discharge port 10, feed port 8, fine powder discharge port 7 are arranged on the top of sub-sieve bucket 9, finished product discharge port 10 is located at the bottom of sub-sieve bucket 9, fine powder discharge port 7 Connected with the negative pressure system, the sieve tray 3 is set in the sub-sieve barrel 9 to separate the feed port 8 from the finished product outlet 10, and the up and down vibration of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com