New bearing cage riveting automatic indexing machine

A bearing cage, automatic indexing machine technology, applied in the field of bearing processing, can solve the problems of high labor intensity, short-range electromagnetic radiation, poor riveting accuracy, etc., to improve production efficiency, reduce labor intensity, and solve high temperature burns. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

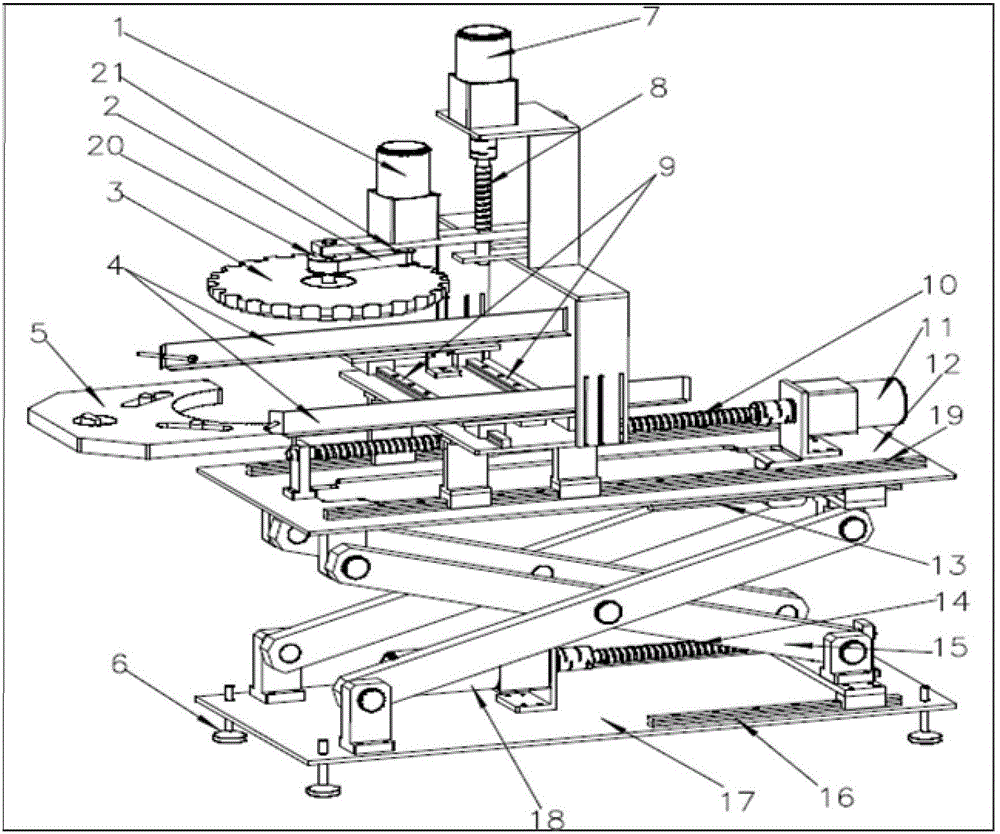

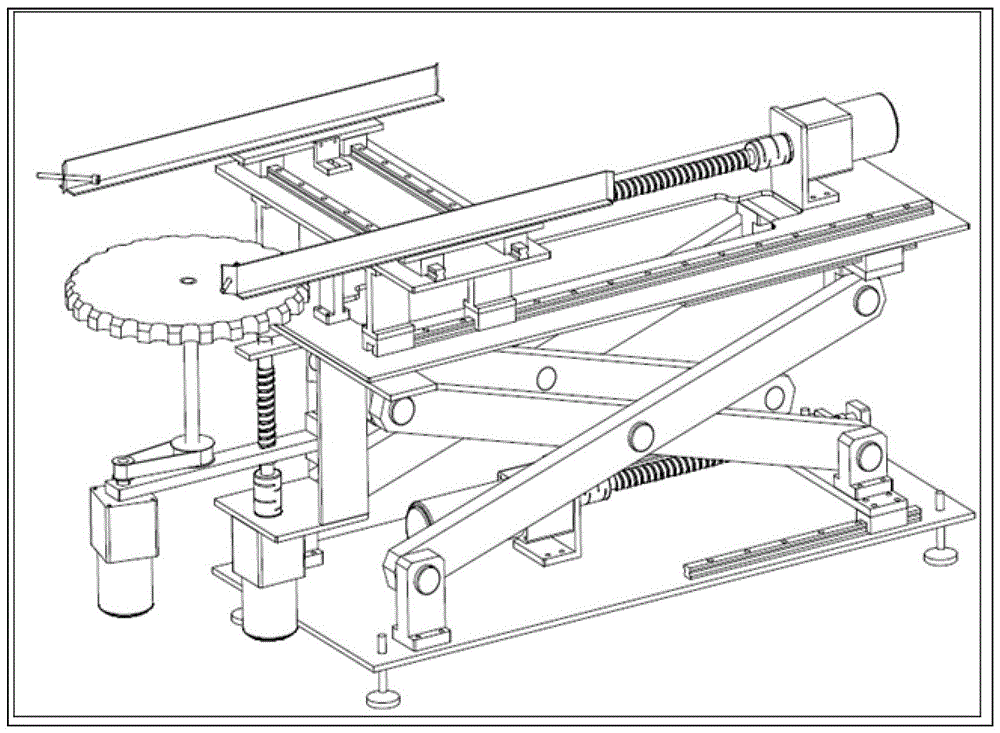

[0040] The structure of the new bearing cage riveting automatic indexing machine of the present invention is as follows: figure 1 shown.

[0041] Set parameters through the touch screen, through PLC logic control, through PLC, servo drive pulse control, through the indexing servo motor 1 to connect the driving shaft and the active synchronous wheel 21, the active synchronous wheel 21 is connected to the synchronous belt 2, and the synchronous belt 2 is connected to the slave The driven synchronous wheel 20 is connected, the driven synchronous wheel 20 is connected with the driven shaft and the faceplate 3, and the faceplate 3 is precisely matched with the semi-finished bearing to realize precise indexing.

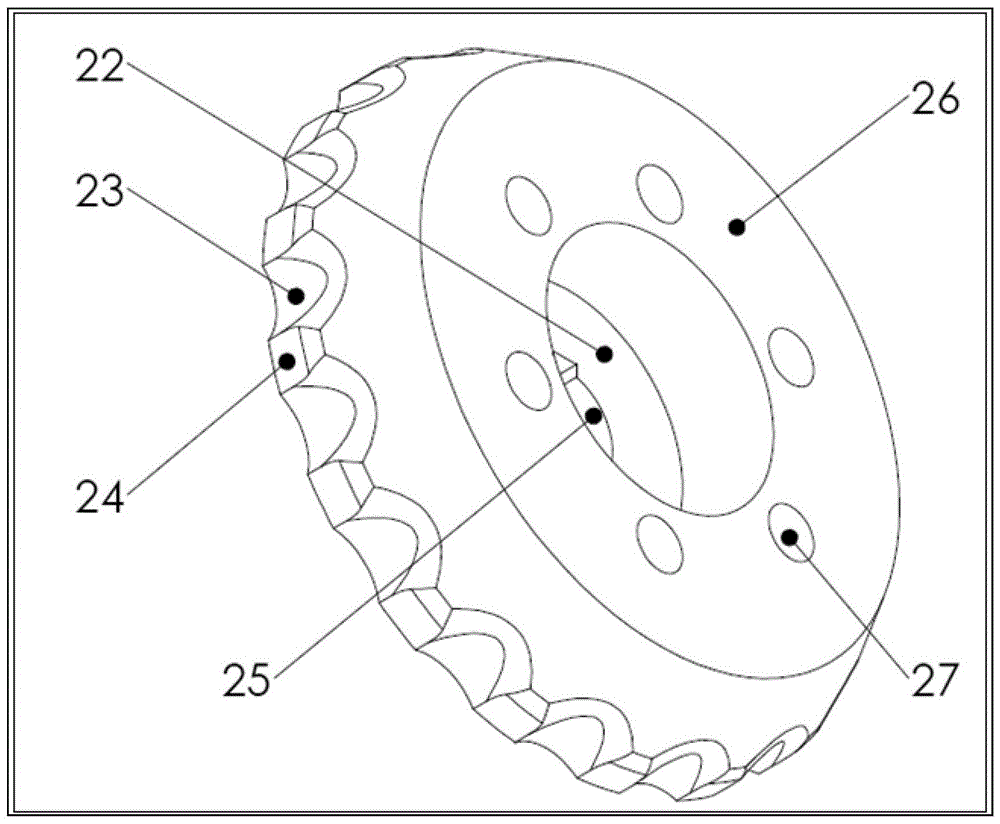

[0042] The highlight of this part of the invention lies in the use of the component faceplate 3 and the servo drive system, and there are specific instructions for the faceplate (such as image 3 ).

[0043] Through the connection of the vertical lifting platform 12 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com