A skimming device for purifying the surface of the core pool

A pool and core technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of personnel contamination, foreign objects and personnel falling into the pool, etc., to ensure the depth of water entry , reduce volume and weight, reduce the effect of construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

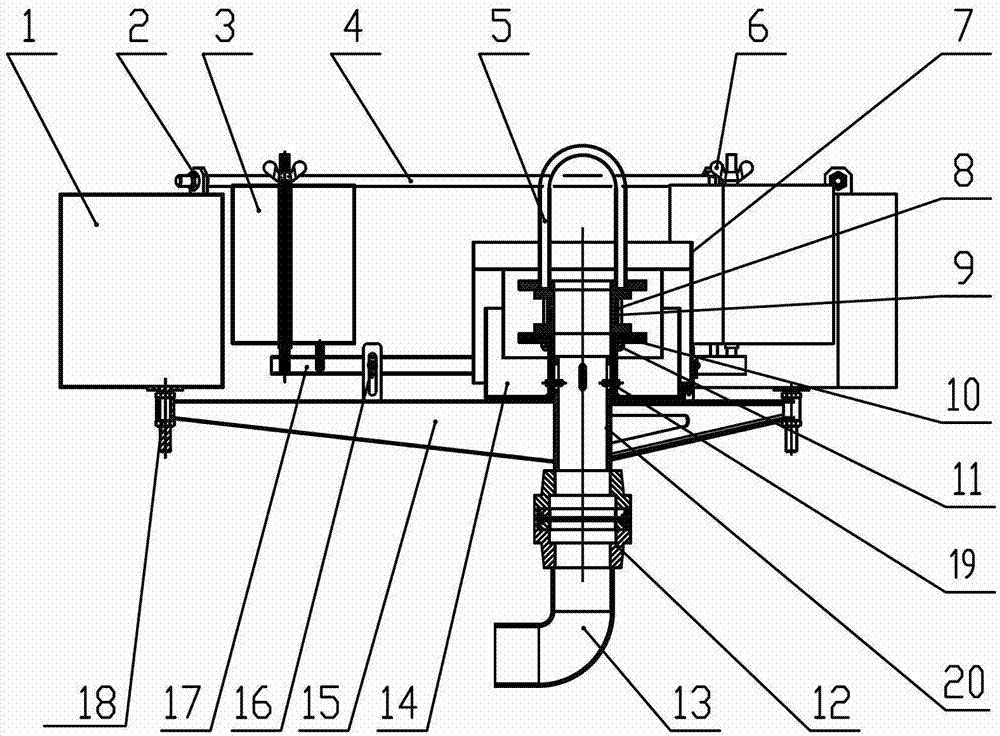

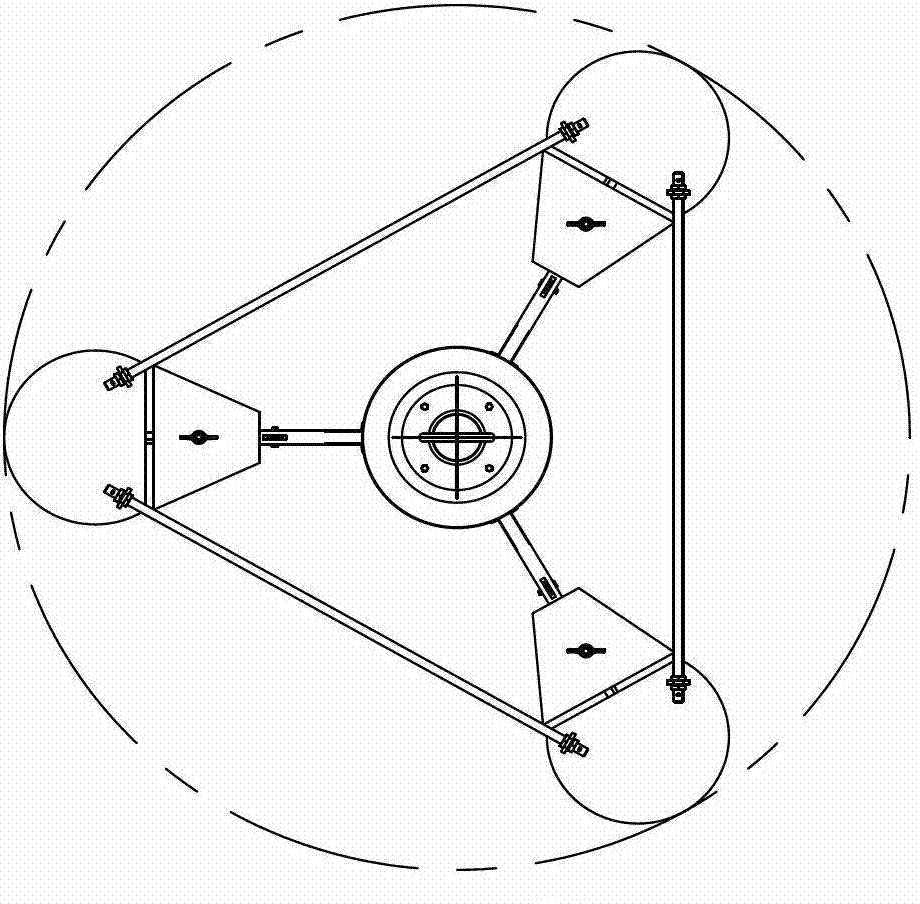

[0017] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] like figure 1 and figure 2 As shown, the present invention is a slag skimming device for purifying the surface of the core pool. Use thin-walled parts with a wall thickness of 2 to 3mm. A wall thickness of 3 mm may be preferred.

[0019] The present invention specifically includes the following devices:

[0020] Three outer buoys 1, three inner buoys 3 and corresponding supporting structures; under the buoyancy provided by the outer buoys 1 and inner buoys 3, the skimming device floats on the surface of the pool, the upper cylinder 7 sinks into the water, and the suction pump The water is pumped out and filtered through the suction elbow 13 and then discharged into the pool; wherein, the outer buoy 1 is a three-quarter cylindrical structure, and the inner buoy 3 is a trapezoidal structure.

[0021] The upper cylinder 7 is a cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com