Environment-friendly ice melting agent prepared by using waste acetic acid produced in dimethyl phthalate production and preparation method thereof

A technology of mosquito repellent and waste acetic acid, which is applied in the environmental field, can solve the problems of difficult purification and recovery, corrosion of carbon steel and reinforced concrete structures, equipment corrosion and large environmental impact, and achieves a high degree of biodegradability, reducing raw material costs, Effect of improving ice melting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

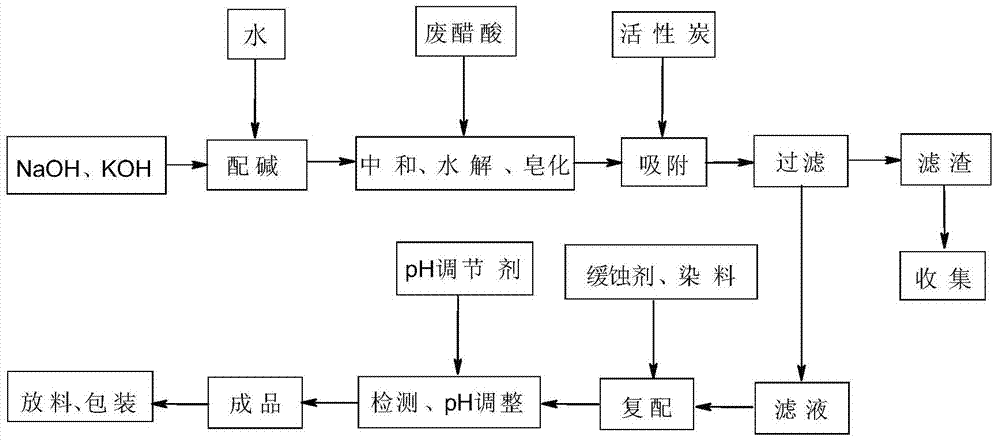

Method used

Image

Examples

Embodiment 1

[0039] Add 42g of sodium hydroxide and 200g of water to the reaction bottle to make lye, dropwise add 50g of waste acetic acid containing acrylate produced in the production of mosquito repellent ester, control the reaction temperature at 70°C, measure the pH value after the reaction, use alkali Liquid adjustment pH9-11. 0.5 g of activated carbon was added to the reaction solution, stirred for 0.5 h, the material temperature dropped to 40° C., and the crude product was suction filtered to collect the filtrate. Add 0.08% sodium dihydrogen phosphate, 0.1% sodium metasilicate, 0.05% sodium tartrate, and 0.02% sodium copper chlorophyllin to the filtrate by mass fraction. Add 1.5 g of acetic acid to adjust the pH to 7.5 to obtain an ice-melting agent product. According to the national standard "Road deicing and snow melting agent GB / T23851-2009", the product's snow melting and ice melting ability, carbon steel corrosion rate and concrete corrosion rate were measured, compared with...

Embodiment 2

[0041]Add 32g of sodium hydroxide to the reaction bottle, add 15g of potassium hydroxide, add 200g of water, make lye, add dropwise 50g of waste acetic acid containing acrylate produced in the production of mosquito repellent, and control the reaction temperature at 80°C. Measure the pH value and adjust the pH to 9-11 with lye. 0.4 g of activated carbon was added to the reaction liquid, stirred for 0.5 h, the temperature of the material dropped to 40° C., and the crude product was suction filtered to collect the filtrate. Add 0.2% sodium dihydrogen phosphate, 0.1% sodium metasilicate, 0.1% sodium tartrate, and 0.02% sodium copper chlorophyllin to the filtrate by mass fraction. Add 1.2 g of acetic acid to adjust the pH to 7.8 to obtain an ice-melting agent product. According to the national standard "Road Deicing and Snow Melting Agent GB / T23851-2009", the product's snow melting and ice melting ability, carbon steel corrosion rate and concrete corrosion rate were measured, com...

Embodiment 3

[0043] Add 42g of sodium hydroxide and 200g of water into the reaction bottle to make lye, dropwise add 50g of waste acetic acid containing acrylate produced in the production of mosquito repellent ester, control the reaction temperature at 75°C, measure the pH value after the reaction, use alkali Liquid adjustment pH9-11. 0.5 g of activated carbon was added to the reaction solution, stirred for 0.5 h, the material temperature dropped to 40° C., and the crude product was suction filtered to collect the filtrate. Add 0.3% sodium dihydrogen phosphate, 0.2% sodium metasilicate, 0.1% sodium tartrate, and 0.02% brilliant blue pigment to the filtrate by mass fraction. Add 1 g of citric acid to adjust the pH to 8.3 to obtain an ice-melting agent product. According to the national standard "Road Deicing and Snow Melting Agent GB / T23851-2009", the product's snow melting and ice melting ability, carbon steel corrosion rate and concrete corrosion rate are measured, compared with sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com